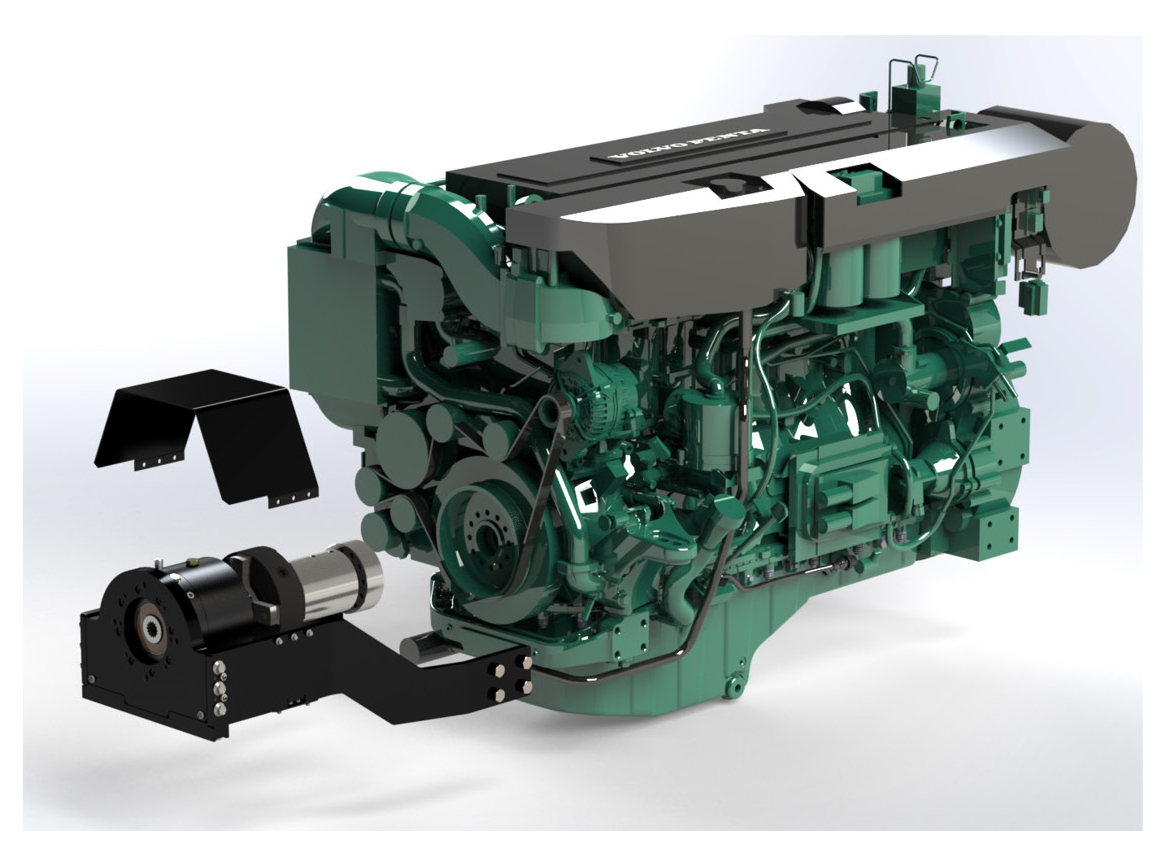

The Logan Front of Engine PTO Clutch mounted to a Volvo D13 provided Frank White the solution he needed to power the hydraulic systems on the Point Break.

Frank White has been fishing for salmon and shrimp in Alaska for over 20 years. His boat, the 39 ft. Point Break uses gillnets and pots powered off the rear of the engine, and refrigeration and bow thrusters powered off the front of the engine.

The Point Break is powered with a Volvo Penta 12.8 liter D13 MH 441 kW / 600 HP engine. In 2020, White wanted to upgrade the Point Break with a refrigeration unit and bow thrusters, but the hydraulic pump on the back of his engine did not have the capacity to support the additional loads.

On White’s previous fishing boat, the Triad, he used a Logan PTO Clutch off of his Detroit Diesel 4.7 liter 4-71 engine to supply power to his hydraulic systems. Pleased with his previous experience, White wanted to return to Logan Clutch. “I loved the Logan clutch so much I put a bigger one on my new boat,” says White. Since there was no room on the back of the Volvo engine, White’s mechanic recommended he find an alternative spot to draw power from. The Volvo D13 did not have any live PTO interfaces to bolt on equipment, so White needed a solution.

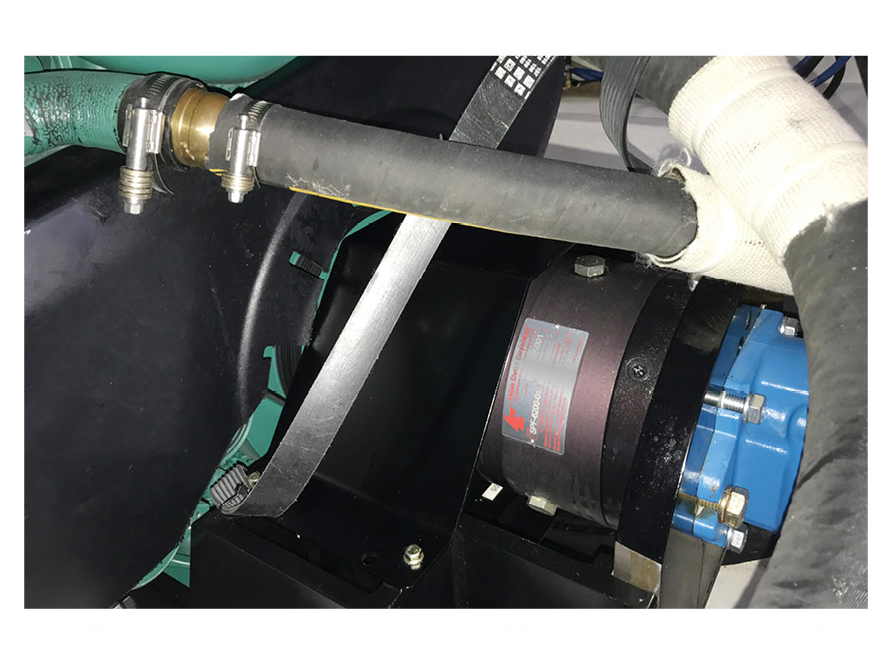

Says White, “A lot of engines that size do have multiple ports for hydraulic applications. This one didn’t. I love this engine (The Volvo D13), but my only option at that point was to put this front mount kit on. I was lucky enough that Logan Clutch could build one.” Using the Logan Front Mount Kit, White was able to equip his Volvo D13 with a Logan 600 Series PTO Clutch to power his new hydraulic systems. The Logan PTO clutch actuates using pressure from the Twin DiscTM transmission. A Logan SOFTSTART™ 24VDC Manifold reduces the 350 psi. transmission pressure to the 200 psi. clutch engagement pressure, allowing for smooth engagement.

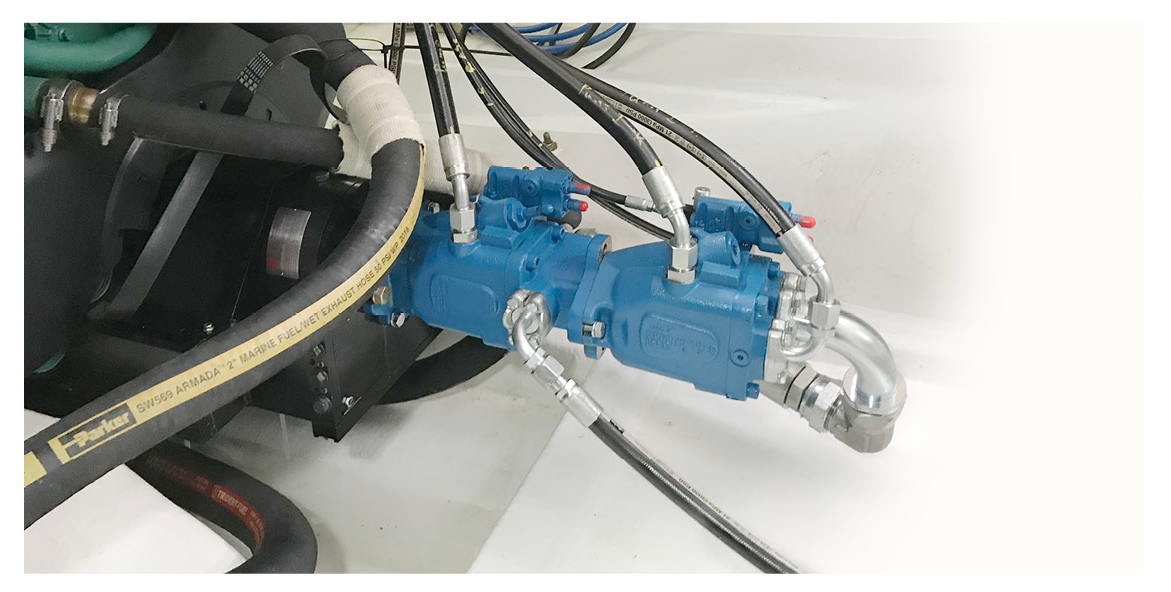

White uses the Logan PTO clutch to engage and disengage hydraulic pumps off the front of his engine for his refrigeration system and bow thrusters. A small hydraulic pump runs the 5 ton nominal RSW refrigeration unit made by Integrated Marine Systems. A larger, 13 cubic centimeter pump powers the NAIAD Dynamics bow thrusters.

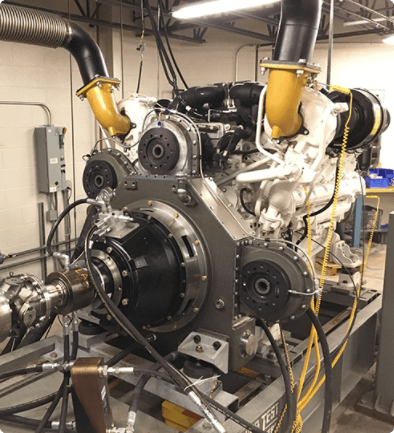

Logan 600 Series Front of Engine PTO Clutch kit Mounted to a Volvo Penta D13 MH engine

On-Demand Clutch Engagement of Hydraulics Reduces Fuel Consumption and Lowers Emissions

By using a Logan clutch to engage and disengage his hydraulic pumps, White is able to reduce fuel consumption and equipment wear by only powering the pumps when necessary. At idle, fuel consumption is roughly ½ gallon/hour. By just engaging the bow thrusters, fuel consumption increases by another ½ gallon/hour to 1 gallon/hour. The Point Break runs for 1000 hours each year. Without a Logan clutch, the hydraulic systems would always be running, so that ½ gallon/hour would account for 500 gallons each year. With fuel costs over $4/gallon, that’s over $2000/year. Further, each gallon of diesel burned produces 22.5 lbs. of CO2, so that additional load would yield 11,250 lbs. or 5.6 tons of CO2 each year. That’s more than a passenger car emits in a year just to power the bow thrusters. As CO2 emissions continue to be a concern, clutch technology enables the additional fuel to be consumed only when necessary.

The Logan PTO Clutch supplies on-demand power via the hydraulic pump for bow thrusters and refrigeration

The Logan PTO Clutch supplies on-demand power via the hydraulic pump for bow thrusters and refrigeration

Logan PTO Clutch Provides Safety and Noise Reduction for Crew Comfort

In addition to reduced fuel consumption and equipment wear and tear, White has noticed the safety and reduced noise of on-demand engagement of hydraulic systems. When it comes to hydraulic systems, White says, “If you don’t have a clutch and there’s a leak, there’s just no stopping the fluid – that’s a safety issue. You can’t shut off the engine if you’re using it to go.” White continues, “It doubles the noise of the engine when you flip on the switch.” The crew onboard benefits from the reduced noise, “It’s that big 13 cube pump screaming away at 2700 psi.,” said Frank, “and I just shut the PTO off and it’s a relief like shutting off the engine.”

Logan’s Exceptional Customer Service

Logan’s tangible benefits of reduced fuel consumption reduced wear and tear, and reduced noise, as well as added safety, are complemented by its customer service. “They don’t make excuses,” says White. Logan always answered the phone and promptly responded. Whenever there was an issue, he’d work with the engineers to figure it out. According to White, “Logan Clutch really shined.”

Click here to learn more about our customer service by contacting us today!