Front of Engine Power Take-Off (PTO) Clutches

Front of Engine PTO Clutches

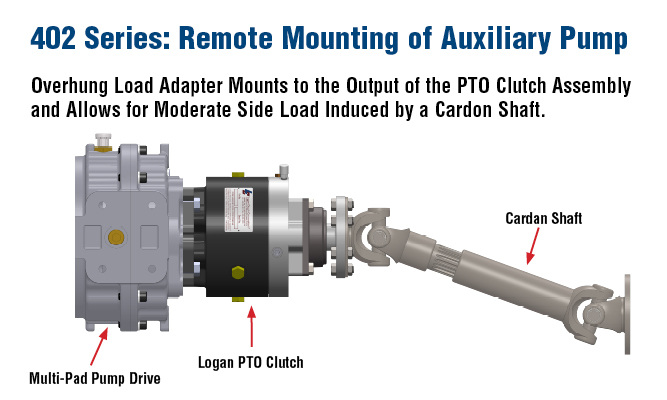

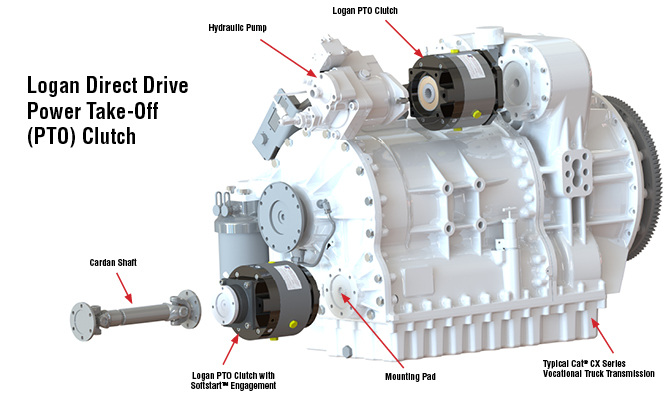

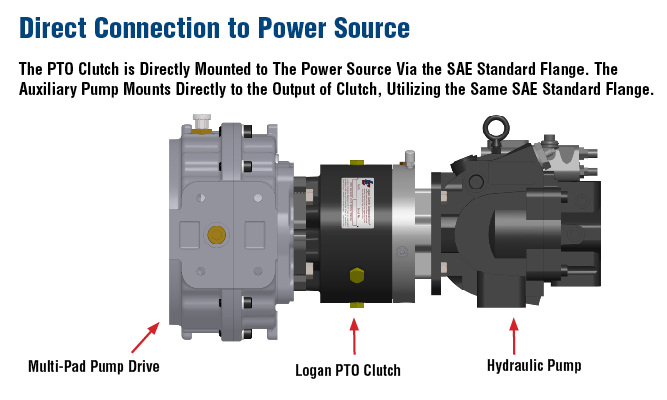

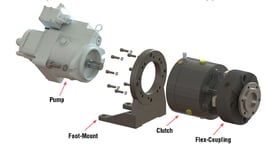

Front of Engine PTO clutches are used in a variety of Industrial, On-Highway, Marine, Construction, Agriculture, Mining, Oil Field, and Rail applications. They are designed to mount between the power take-off of the engine and auxiliary attachment, i.e. single or multi-station pump drive.

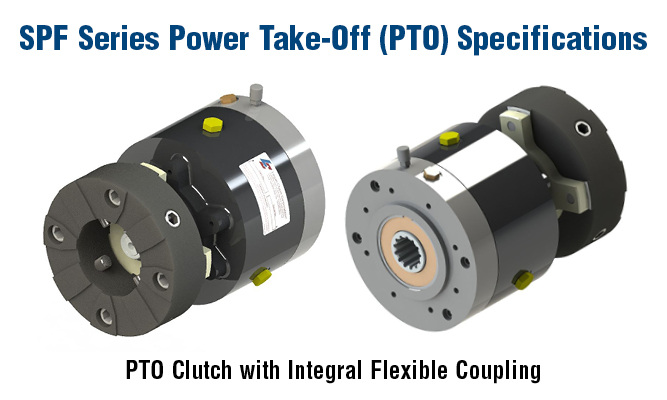

Logan Air / Fluid actuated Bell Housing PTO™ clutches are Self-Adjusting™ and designed to mount directly to a diesel or gasoline engine’s flywheel.

Applications

- Single and multi-station pumps

- Mobile or stationary auxiliary drives

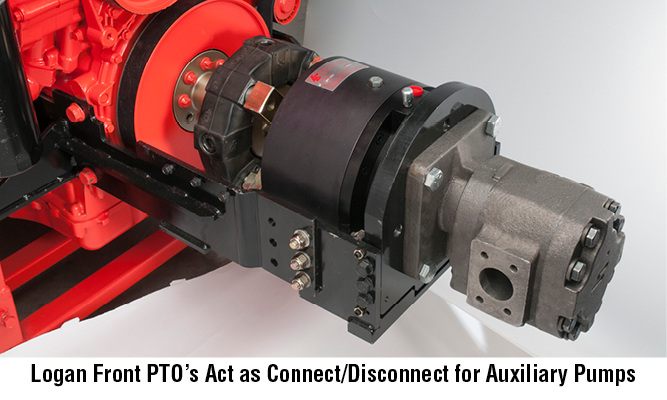

- Connect / disconnect direct drives

- Winches, reels, hoists and more

Advantages:

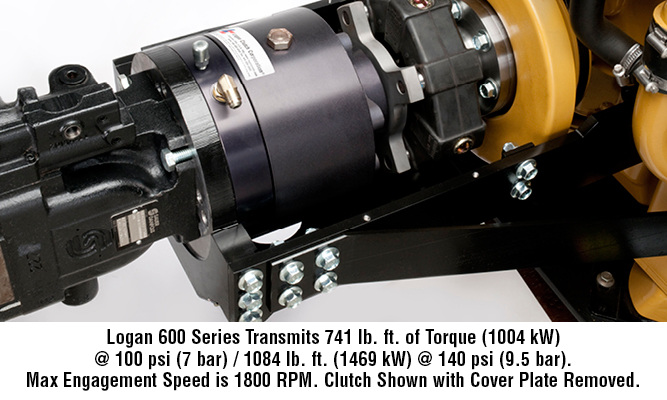

- Simple, efficient, high-torque design

- Reduces fuel consumption and CO2 emissions: engaging drives and pumps (only when required)

- Easier-engine starts: lowers horsepower draw and cranking power required during machine start-up by disconnecting the hydraulic system from the engine

- Reduces ambient noise: through intermittent use of pumps and equipment

- Cooler running hydraulic systems: heat is generated whenever oil dumps from high to low pressure without producing work. Disconnecting the PTO Clutch reduces the destructive effects of heat – lowering maintenance costs and hydraulic oil requirements

- Extends the life of drive systems and components

Front of Engine PTO Products:

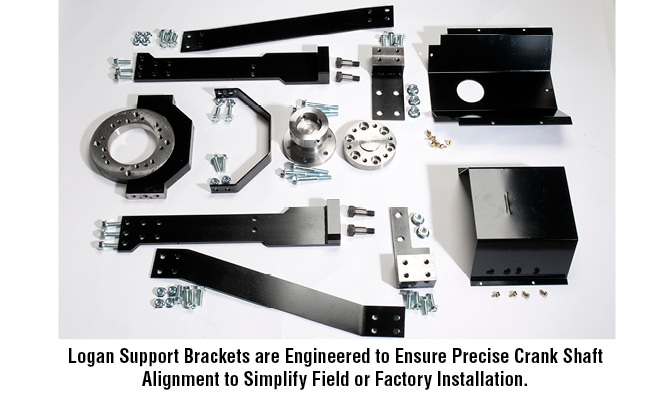

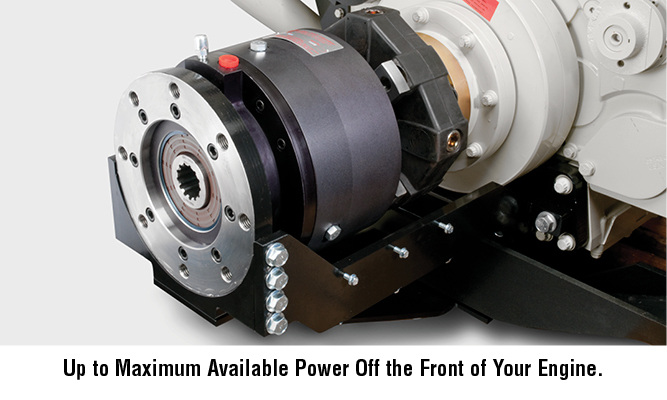

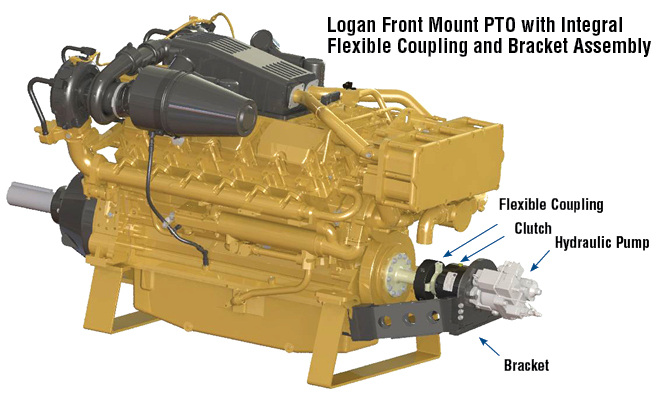

Front PTO Mounting Options

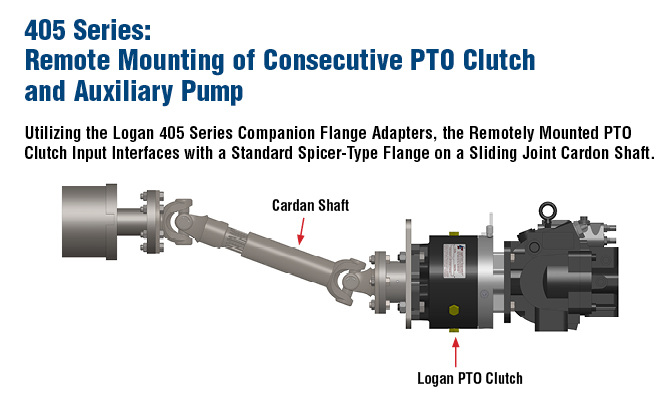

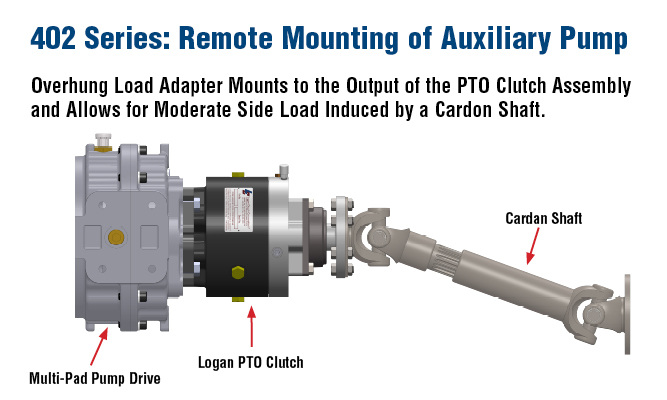

Logan Front of Engine Power Take-off (PTO) Clutches come with a variety of mounting options to fit the needs of your engine

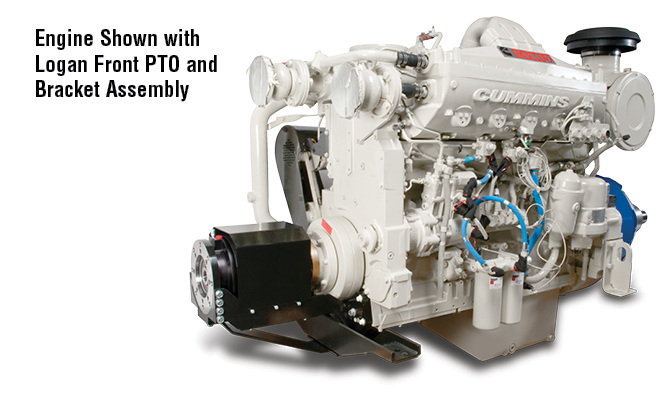

Front PTO Cummins Diesel Engines

Logan Front Mount PTOs are easily installed with simple hand tools on a variety of Cummins Diesel Engines using the Logan-engineered mounting bracket for precise alignment

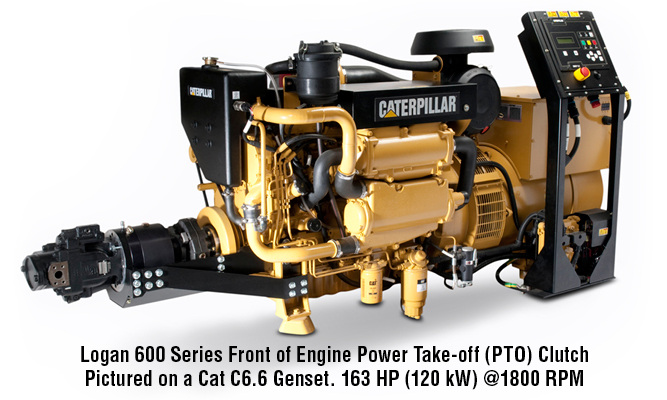

Front PTO CAT C6.6 and 4.4

Logan Front Mount PTOs are perfect for auxiliary attachments on the front of Cat6.6 and 4.4 Diesel Engines

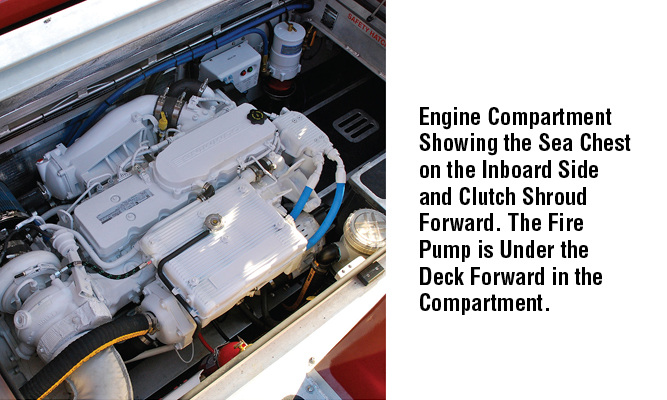

Front PTO Scania D12 and D16 Marine Engines

Logan Front Mount PTOs work for a variety of marine applications with the Scania D12M and D16M Diesel Engines and Generator Sets

MAN i6-800 Diesel Engine

Logan Front of Engine PTO Clutches – On-Demand Power for Hydraulic Pumps, Winches, Reels, and Hoists

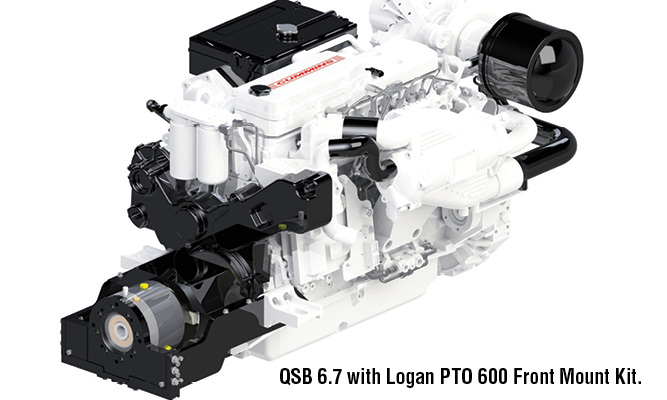

Front PTO Cummins QSB 6.7 QSB 7

Logan Front Mount PTOs are easily installed with simple hand tools on Cummins QSB 6.7 Diesel Engines and QSB 7 Generator Sets using the Logan-engineered mounting bracket for precise alignment

Front PTO John Deere 4045T

Logan Front Mount PTOs fit a variety of John Deere engines, including the popular John Deere 4045T Diesel Engines

Front PTO Scania D12 and D13 Marine Engines

Logan Front Mount PTOs for Scania D12M and D13M Diesel Engines and Generator Sets is an ideal solution for powering auxiliary equipment

KOHLER Diesel Genset

Logan Front of Engine PTO Clutches for KOHLER Generator Set Models 33kW to 200kW

Logan Clutch Front Mount Kits For Volvo Penta Engines

Volvo D11 Diesel Engine 510 - 626 HP (375 - 460 kW), Max. Torque 1365 - 1594 Lb.ft (1851 - 2161 Nm)