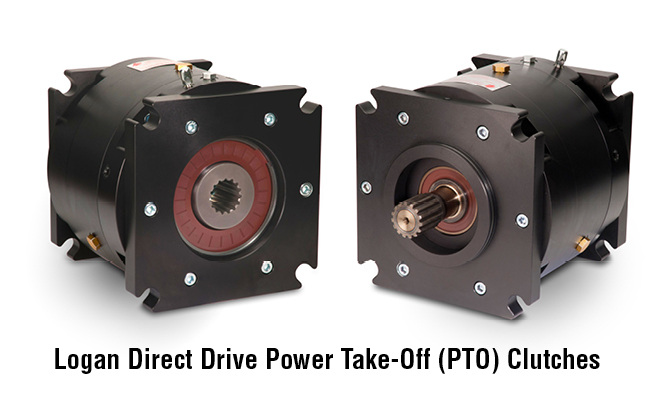

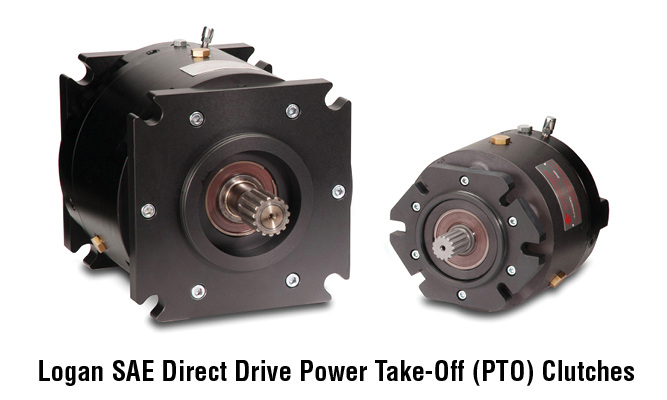

SAE Direct Drive PTO Clutches

Simple, Efficient, High-Torque Design

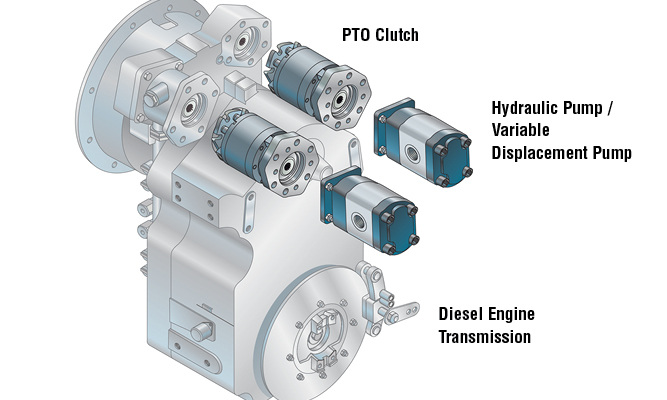

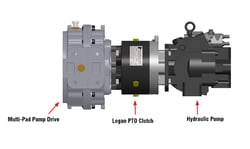

Logan Power Take-off (PTO) clutches are self-contained, heavy-duty, corrosion resistant design - and mount between the live auxiliary PTO pad of your engine, gearbox, or transmission, and auxiliary attachment or pump drive. Applications include a variety of Industrial, On-Highway, Marine, Construction, Agriculture, Mining, Oil Field, and Rail applications.

Benefits:

Experience reduced fuel consumption, lower emissions, and extended service intervals by engaging the drive only when needed. Additional benefits include quieter operation through intermittent pump use and lower horsepower demand during cold starts or machine start-up. For example, disconnecting the hydraulic drive system during engine start-up, Logan SAE PTOs helps optimize performance and efficiency.

Capacity: Industry leading Torque ranges from 200 lb. ft. to 2200 lb. ft.

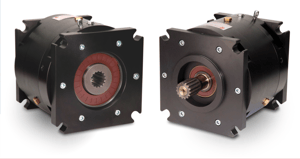

PTO Clutches - How They Work

Logan PTO Clutches are hydraulically

or pneumatically actuated, and self-contained within a rugged, light weight corrosion resistant housing, that does not require external shielding. A splash oil bath provides lubrication to the multiple disc, self-adjusting, wet clutch pack.

Pressurizing the cylinder, forces the piston to clamp and lock the friction and separator discs. When pressure is removed, release springs separate the separator discs, which provides a running clearance between discs when the clutch is disengaged. In the event of power disruption, (ABS type approved) manual engagement screws are

used to mechanically engage the clutch.

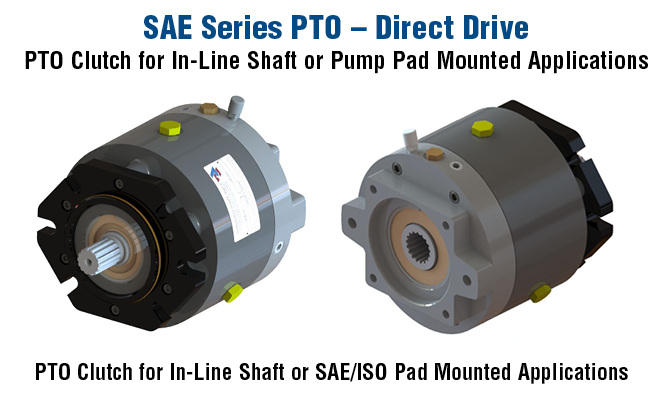

Mounting Options:

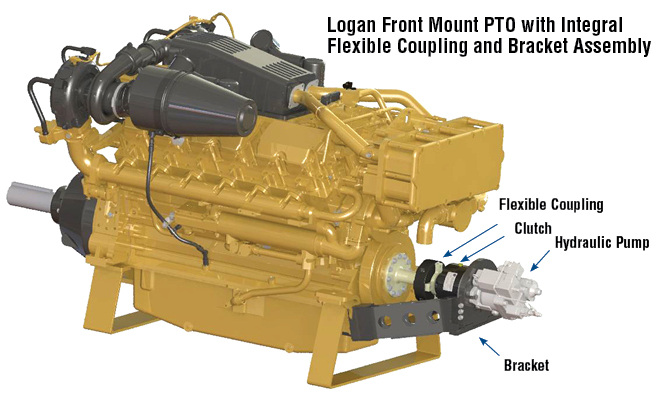

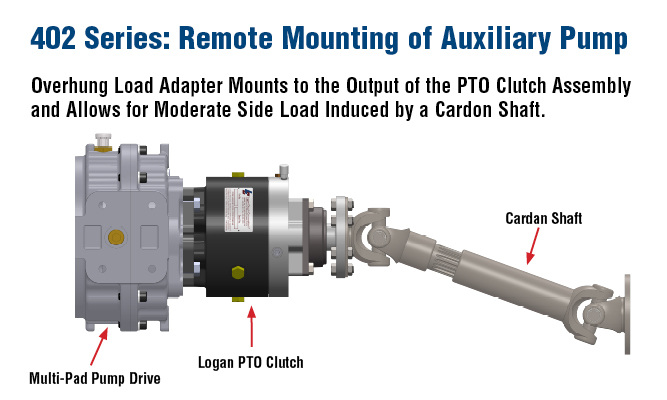

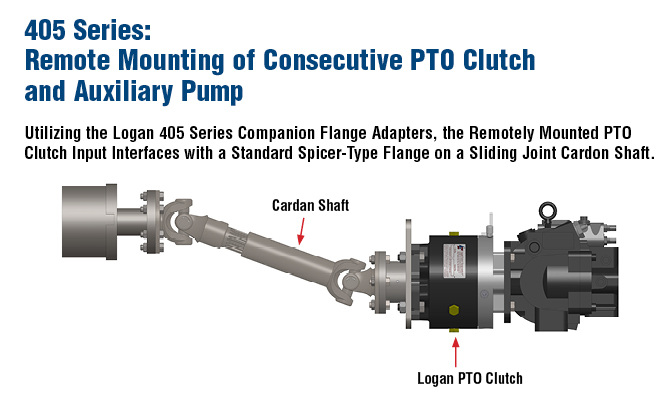

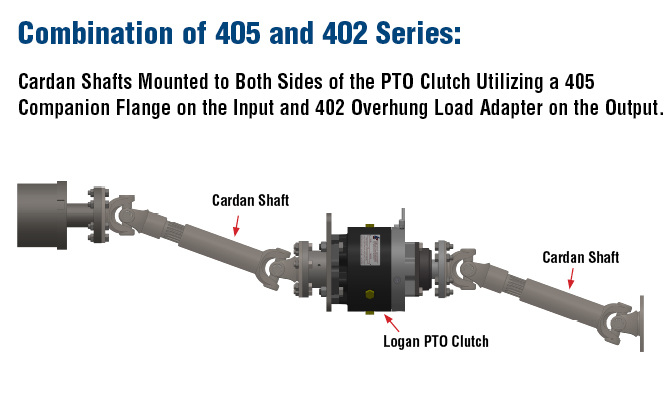

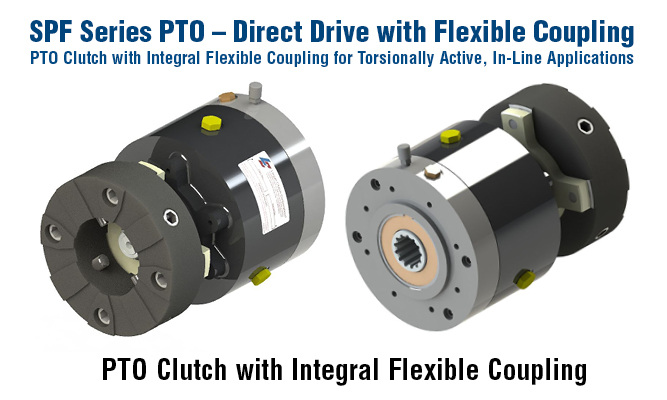

Ideal for in-line shaft or pump pad applications from an engine, or PTO pad. SAE or ISO mounting flanges. Available in A, B, C, C-C, D/E, E and F splines, plus bore and keyway configurations. Overhung Load Adapters (OHLA) are also available in common Dana or DIN style flanges. Integral torsional couplings available.

Standard Specifications:

Standard Logan SAE PTO’s have input torque ranges from 159 lb. ft. (216Nm) to over 3,000 lb. ft. (4068 Nm).

Operating Speeds:

Operating range from 1 to 3,000 RPM under load conditions.

Modified Standards:

Higher horsepower, torque ranges, speeds, actuation pressures, and design configurations are available to meet customer's specific design requirements.

PTO Clutch Applications

- Single and multi-station pump drives

- On and off-highway transmissions

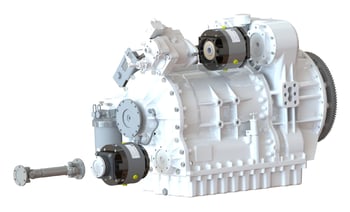

- Marine transmissions

- Mobile or stationary auxiliary drives

- Connect / disconnect direct drives, winches, reels, hoists, and more

- Connect-disconnect clutch between engine and electric or permanent magnet motor drives

Advantages:

- Heavy-duty, self-contained corrosion-resistant design requires no external lubrication

- Air or hydraulically actuated. Self-adjusting, multiple-disc pack design

- Smooth engagement / disengagement

- Simplified, compact, high-torque design

- Remote activation from a control panel or operator's station

- Optional manual engagement screws (should power flow be disrupted)

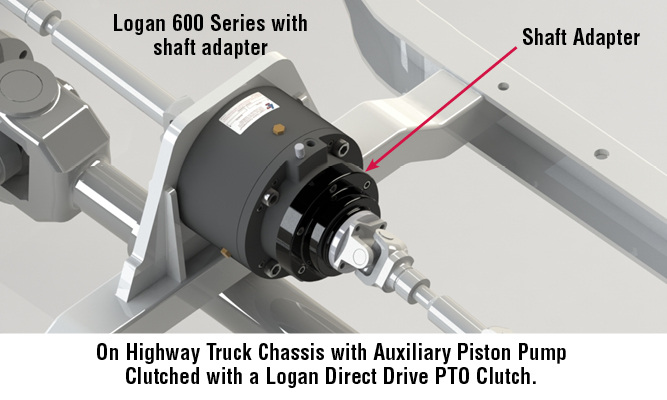

- Optional shaft adapters and overhung load adapters for Dana or Spicer style flanges

- American Bureau of Shipping (ABS) type approval

- Oil bath for flow through cooling

SAE PTO Products:

Mobile Applications

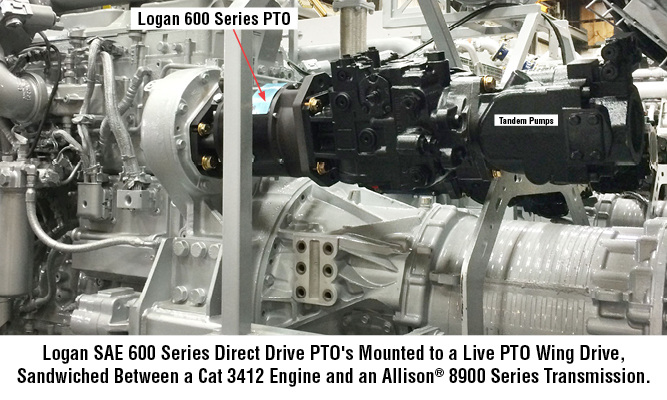

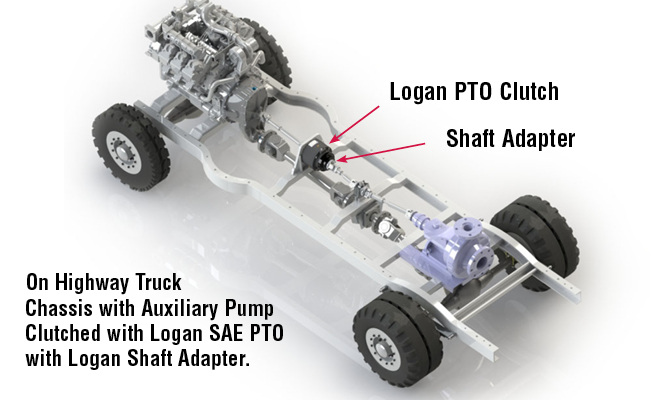

Logan SAE PTO Clutches are designed to mount between the power take-off of an engine and an auxiliary attachment, i.e. sandwiched between the live PTO and hydraulic pump, or as a connect-disconnect for a driveline.

Direct Drive Side PTO Clutches for Allison Transmissions

Logan Hi-Capacity, Soft-Start PTO clutches for Allison 3000 and 4000 Series Transmissions.

HPU Hydraulic Power Units – Manifolds and Start-up Kits

Logan offers Hydraulic Power Units, Softstart Manifolds and Start-up kits, which are designed to simplify Logan Clutch installations and to provide reliable engagement of your Logan Clutch.

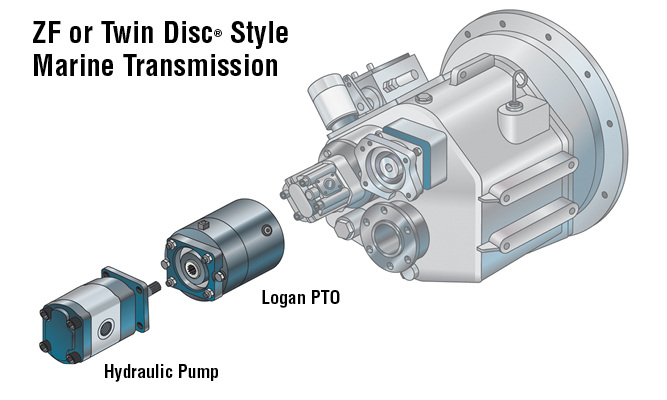

Marine Applications

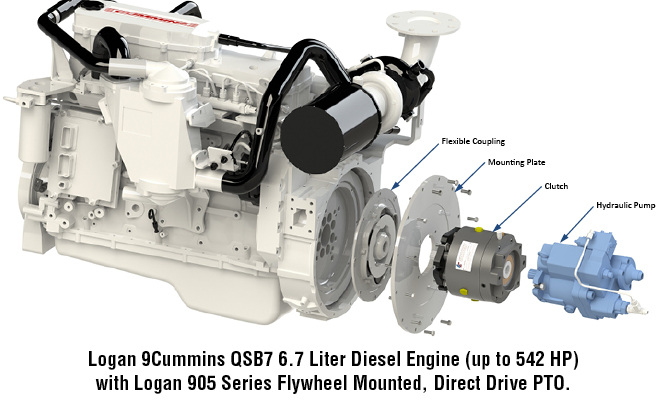

Logan SAE PTO Clutches are designed to mount between the power take-off of an engine, marine transmission, or genset.

Optimizing REPTO Applications with Logan Direct Drive PTO Clutches

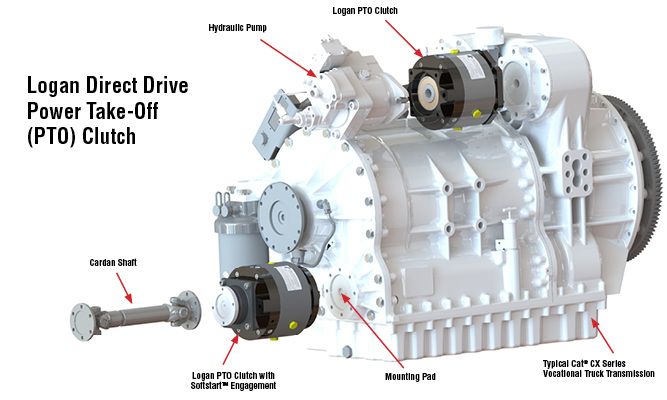

Logan Direct Drive Power Take-Off (PTO) clutches provide a robust and efficient solution for Rear Engine PTO (REPTO) applications in on-highway vehicles.

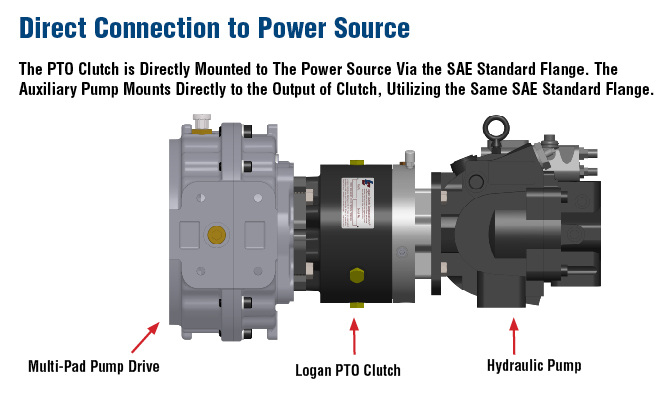

PTO Clutch Mounting Options

The PTO clutch is directly mounted to the power source via the SAE standard flange. The auxiliary pump mounts directly to the output of clutch, utilizing the same SAE standard flange.