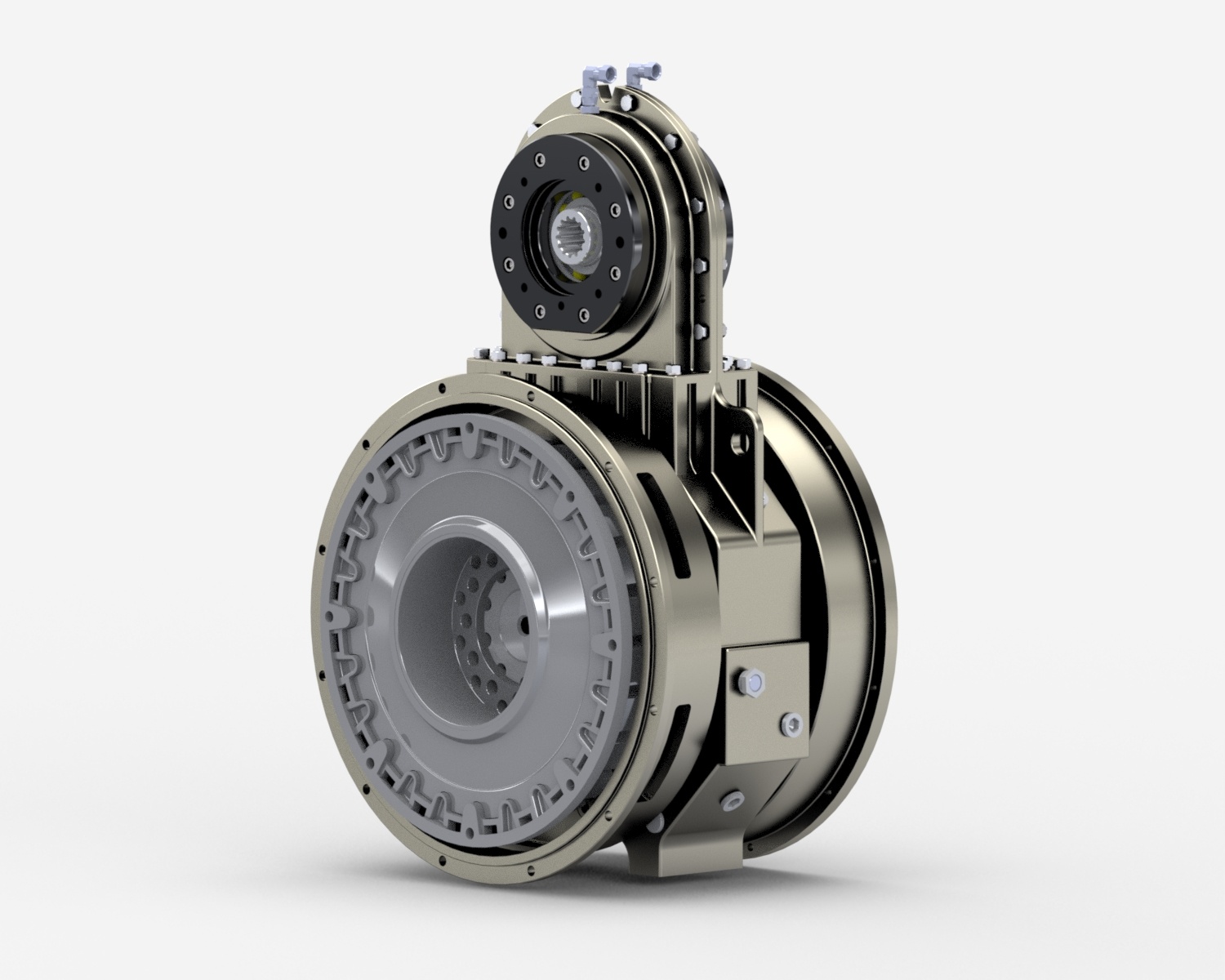

FlexaDrive™ Mobile

The Logan FlexaDrive™

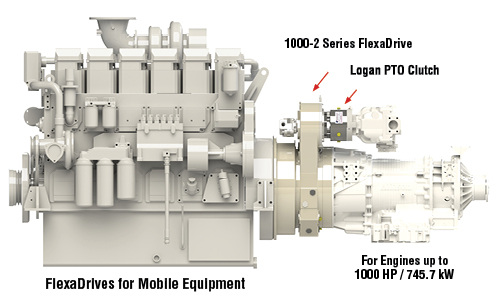

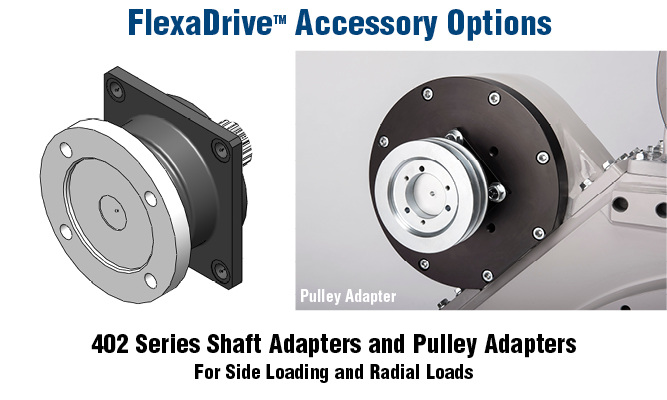

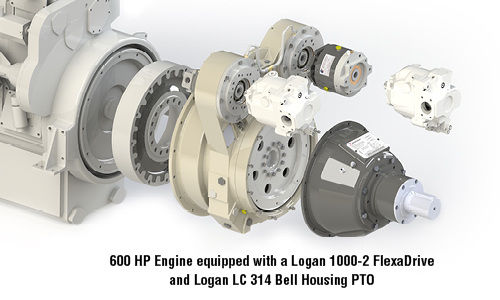

Logan FlexaDrives are designed to mount directly to popular SAE flywheel housings, with typical sizes ranging from an SAE No. 3, No, 2, No. 1, up to a No. 0 size.

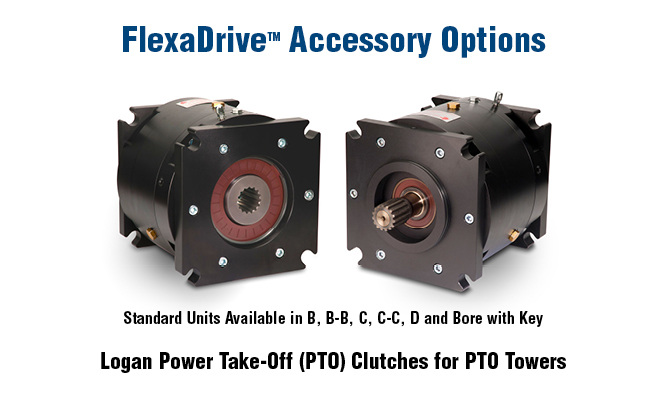

Optional Logan direct-drive PTO clutches offer on-demand engagement for hydraulic pumps, axial motors, electric drives, and other attachments, eliminating the need for continuous operation.

Incorporating a Logan FlexaDrive and PTO enables OEMs to significantly cut fuel use and emissions, extend driveline life, and reduce maintenance and downtime by activating drives only when needed, enhancing operations and efficiency.

Applications:

-

Hybrid Drive Systems

-

Marine Propulsion

-

Mobile Equipment

-

Industrial Skid Mounted Systems and Gensets

-

Railway Locomotives and Maintenance Equipment

-

Rock Crushing and Mineral Processing

-

Environmental and Recycling Equipment

-

Tree and Brush Chipper

Advantages:

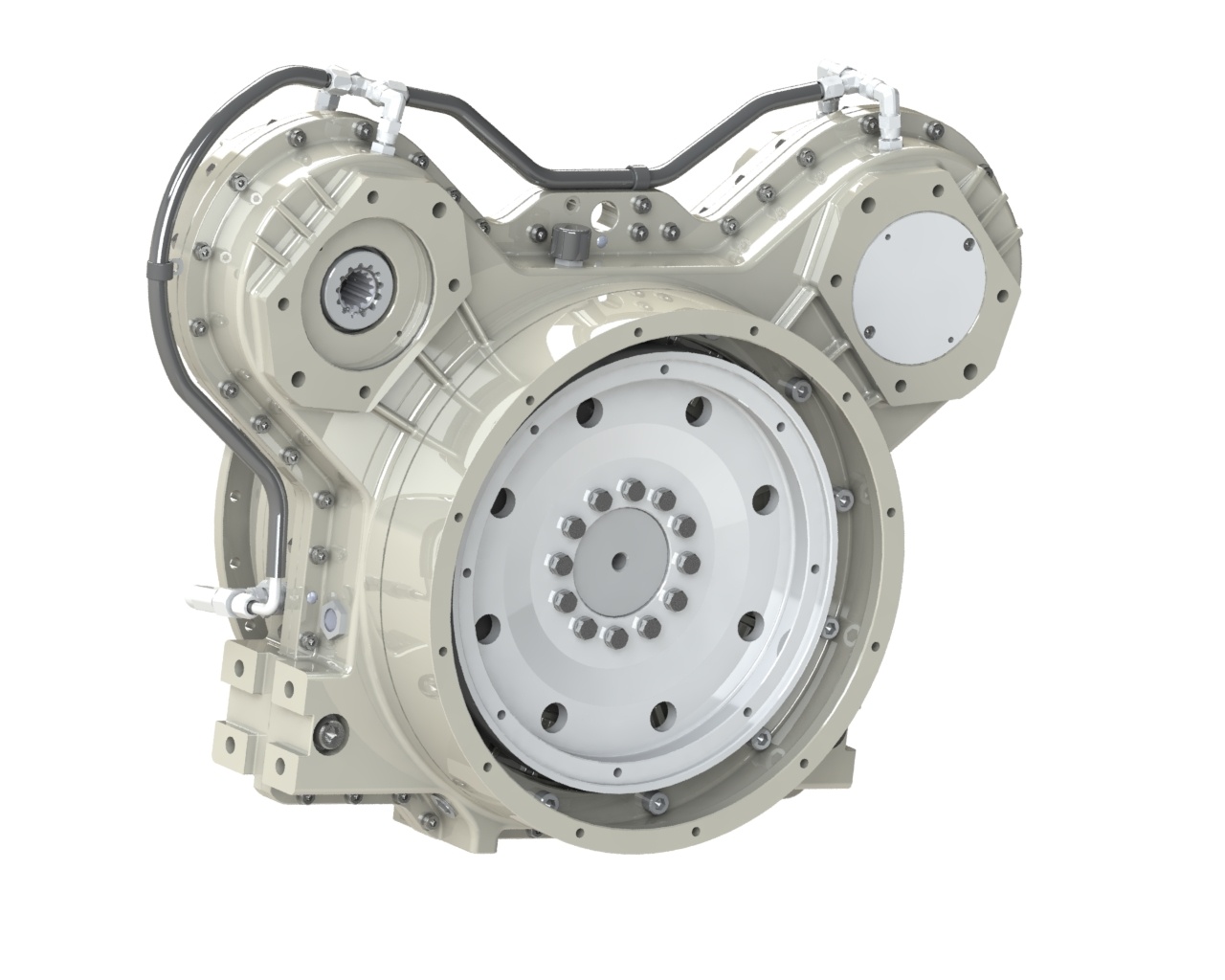

- Up to (4) live PTO/PTI positions

- Short axial length, plus full torque transmission

-

Available in: SAE 1, 2, 3 and 0 Bell Housing sizes

-

Flexible couplings in: SAE 11.5”, 14” and 18” flywheel sizes

-

Up to 1000 HP or 745 kW @ 2200 RPM

-

Short axial length, plus full torque transmission

FlexaDrive™ Mobile Products:

1-Position Pump Drive-800 HP

Rated at 800 HP / 600 kW under continuous duty, the Logan FlexaDrive is a self-contained, single tower, multiple pump drive gearbox, which provides full engine power between your engine (power take-off) and transmission. Logan 800-1 FlexaDrive input and output housings mount to standard SAE No.1, No. 2 and No. 3 flywheel housings (SAE J617 and SAE J617 Flywheels) and to any specified drive shaft. FlexaDrives can be positioned up to 90º in either direction.

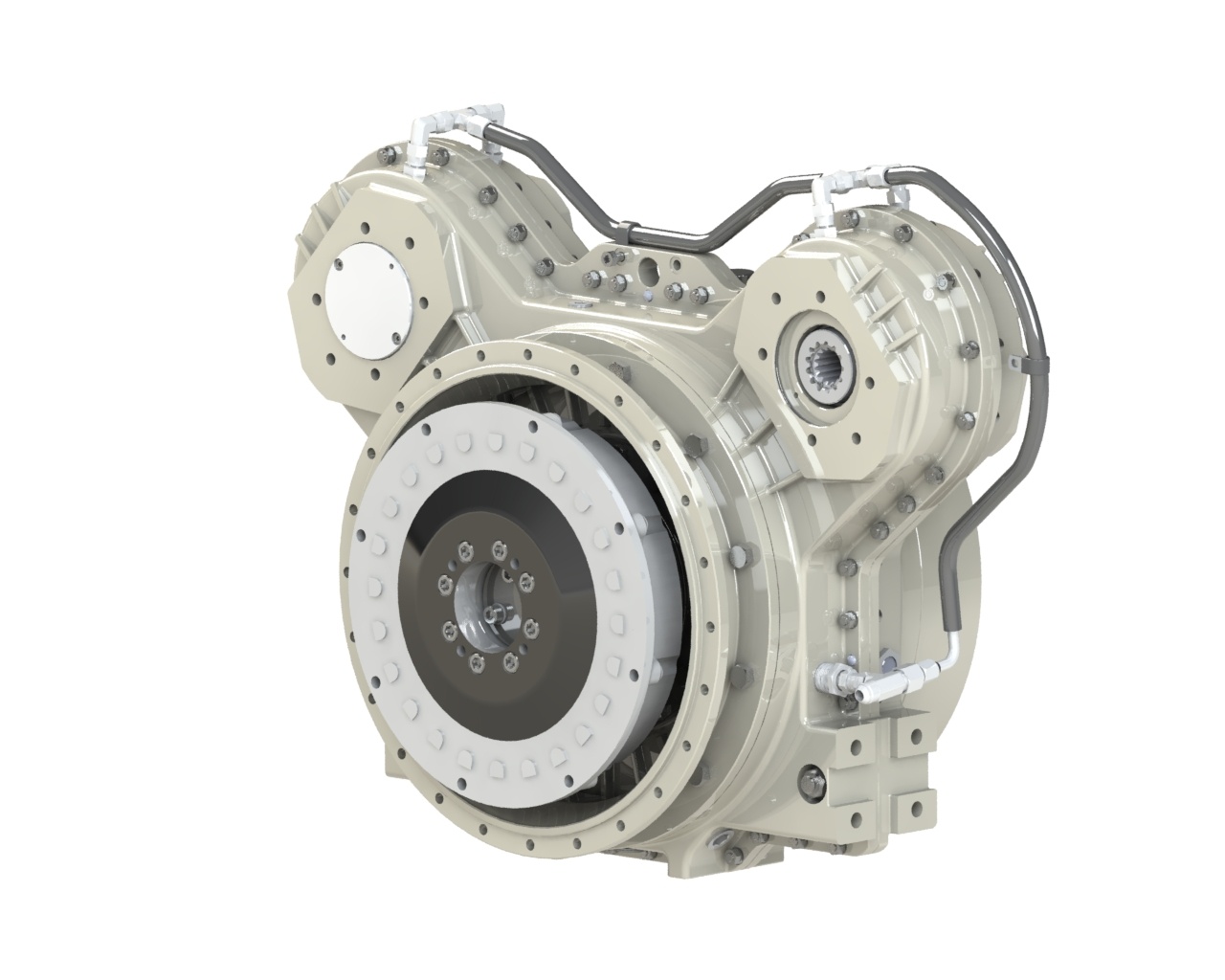

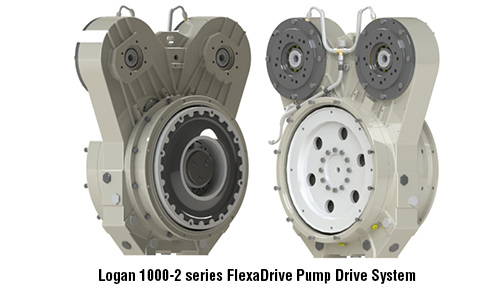

2-Position Pump Drive - 1000 HP

The Logan 2-Position Pump Drive is outfitted for up to four (4) PTI/PTO pads, and can accommodate up to 1000 HP / 745 kW Engines, with maximum speeds up to 2200 RPM and total heads capacity of 320 HP / 240 kW. A single head has a maximum 160 HP/120 kW. Various step-up gear ratios are available for direct drive PTO's. A single head has a maximum 160 HP/120 kW. Various step-up gear ratios are available for direct drive PTO's. Available with standard SAE #0 and SAE #1 inputs and outputs or special direct drive adapters.

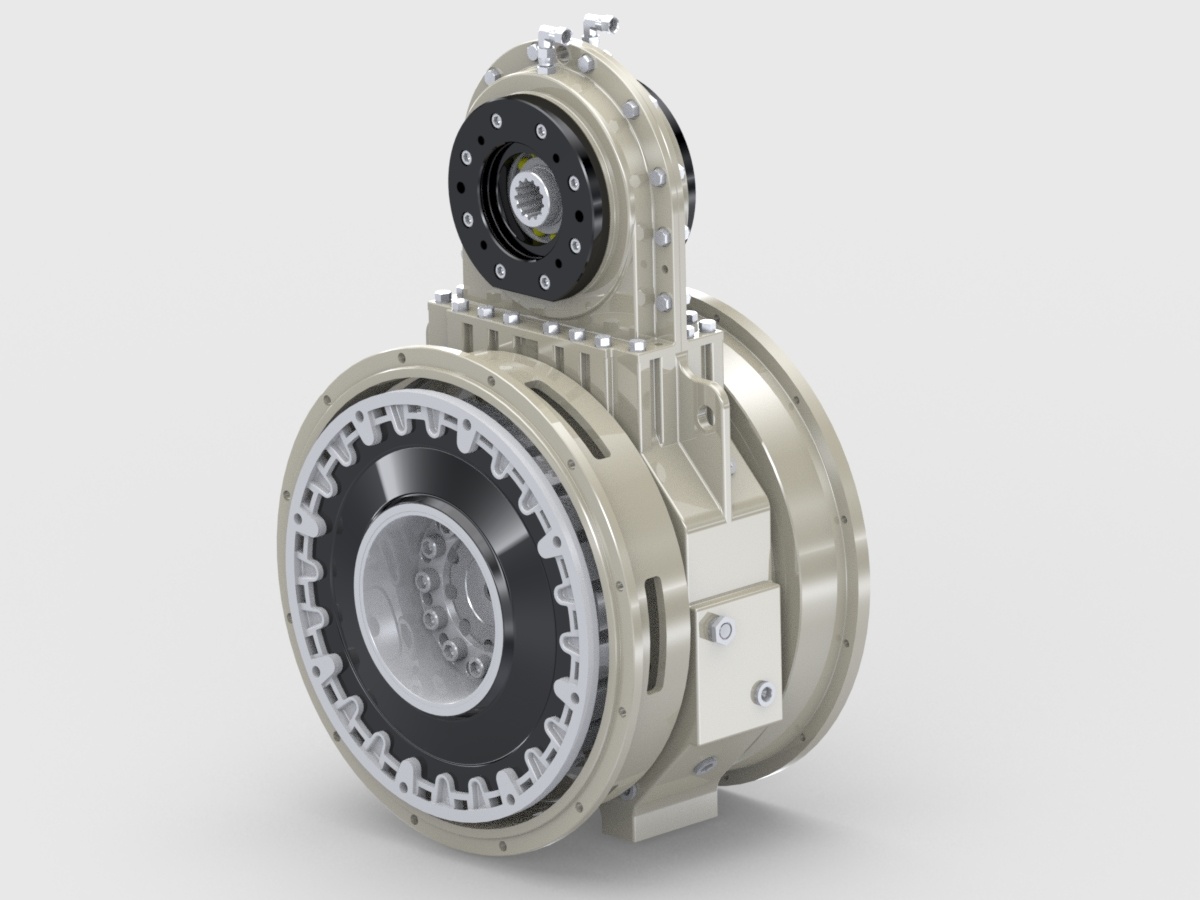

Two-Position Pump Drive - 700 HP

The Logan 2-Position Pump Drive is outfitted for up to four (4) PTI/PTO pads and can accommodate up to 700 HP / 522 kW Engines, with maximum speeds up to 2200 RPM. Total heads capacity of 300 HP / 225 kW. A single head has a maximum 160 HP/120 kW. Various step-up gear ratios are available for direct drive PTO's