Screw Machines

Screw Machine

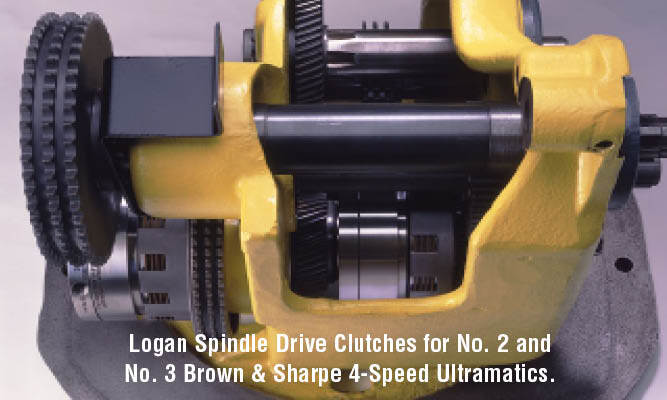

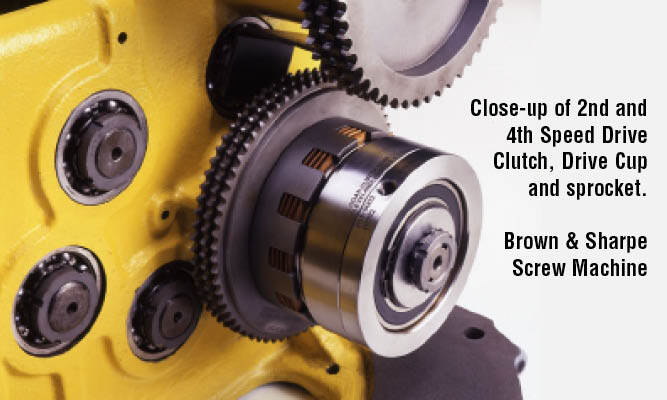

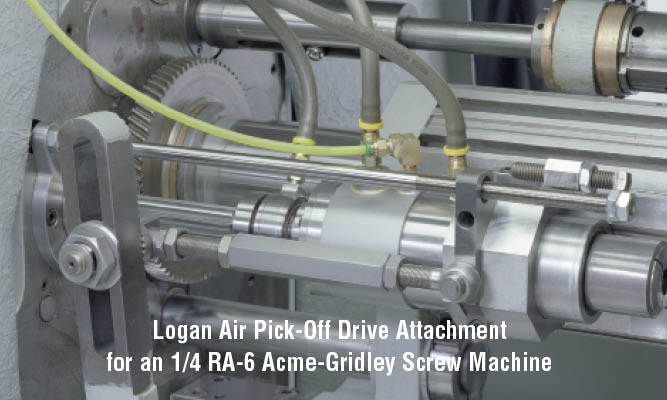

Logan Clutch Corporation is an OEM manufacturer of hydraulic and air actuated clutches. They are used in Acme-Gridley, New Britain, Wickman, Davenport, Warner & Swasey, Euroturn, and Gildemeister Screw machines. In addition, Logan manufactures screw machine controls, (microprocessor controls) and real-time data collection software to use in conjunction its control system.

Logan Air / Fluid actuated Bell Housing PTO™ clutches are Self-Adjusting™ and designed to mount directly to a diesel or gasoline engine’s flywheel.

Where Used:

- Acme-Gridley

- New Britain

- Euroturn

- Davenport

- Wickman

- Conomatic

Advantages:

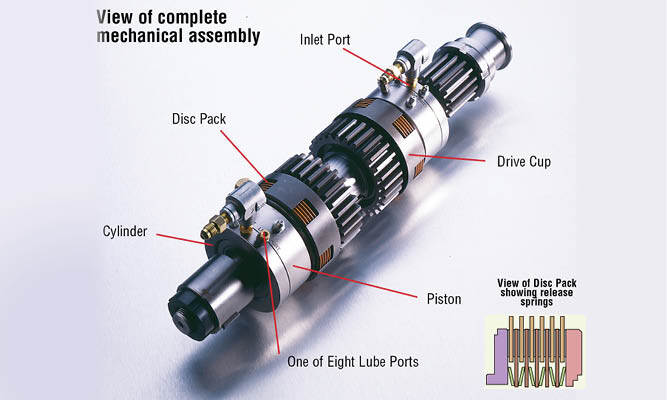

- Self-adjusting disc pack (no slippage)

- Extremely accurate - uniform thread depth over millions of parts

- Large cylinder: piston area for maximum torque

- Up To 200% more torque than mechanical clutches

- Simple to install

- Most Logan Air Threading™Clutches utilize existing clutch drive cups, (clutch gears), spacers and shafts

- Increase tap life through positive clutch engagement

- Eliminates mechanical linkages lever arms, adjusting collars, dog levers, spring pins, yokes, clutch sleeves, etc.

- Eliminates mechanical clutch adjustment

.jpg?width=340&height=150&name=XTP1b__1677545937%20(1).jpg)