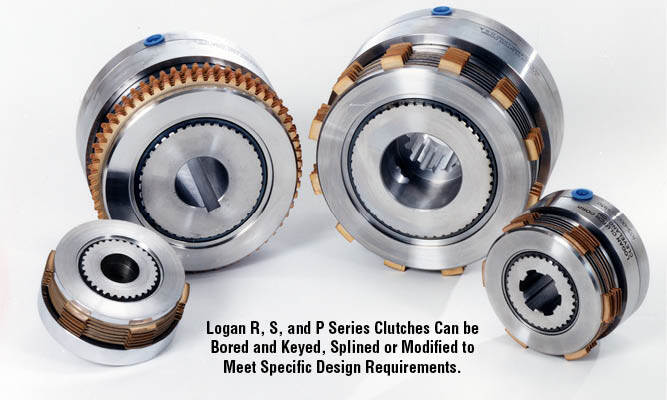

Industrial Hydraulic Clutches and Pneumatic Clutches

Simple, Compact, High Torque Design

Logan Fluid or Air actuated clutches, brakes, and clutch-brake combinations are used in a wide variety of Machine Tool, Industrial, Marine, Municipal, Mining and Off-Highway applications. Our attention to quality and service, along with the ability to modify standard units to meet specific customer needs, has led to the success and growth of Logan Clutch Corporation.

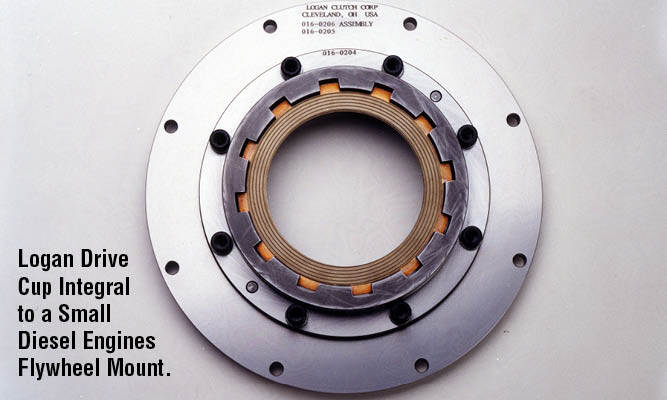

Logan Air / Fluid actuated Bell Housing PTO™ clutches are Self-Adjusting™ and designed to mount directly to a diesel or gasoline engine’s flywheel.

Applications

- Machine Tools

- Industrial

- Construction

- Agriculture

- Marine

- Mining

- Rail

- Oil Field

- Lawn & Turf Equipment

Advantages:

- Maximum torque / minimum envelope

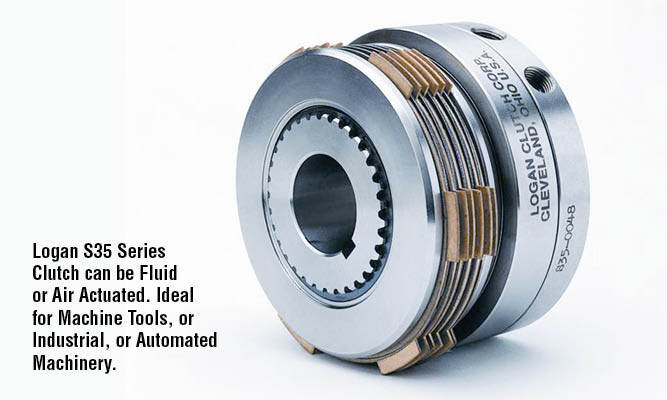

- Hydraulic or pneumatic actuation

- Wet or dry operation

- Fast engagement / Quick release

- Minimal freewheeling drag

- Compact design

- Custom bore diameters / Keyways

- Modified standards for specific design requirements

- Increased torque and RPM capability

- Geared friction disc and drive cup interface

- Custom drive cups

- Forced cooling & Thrust bearing lubrication

- Mounted for use as a power-applied brake

Industrial Hydraulic Clutches and Pneumatic Clutches

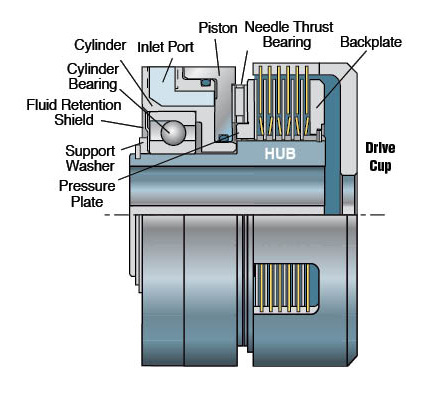

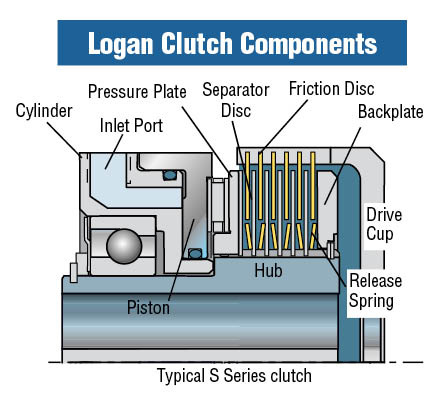

S Series

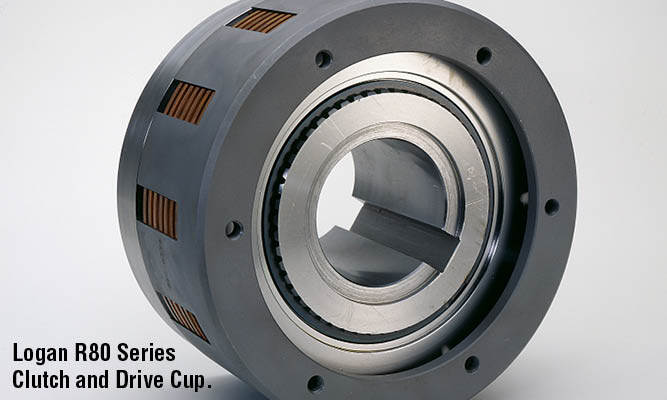

R Series

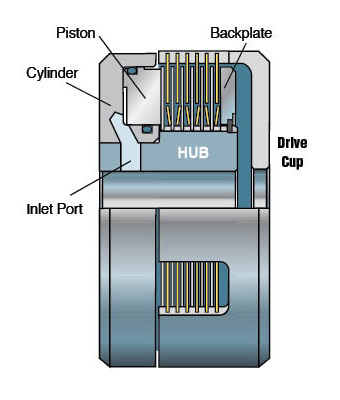

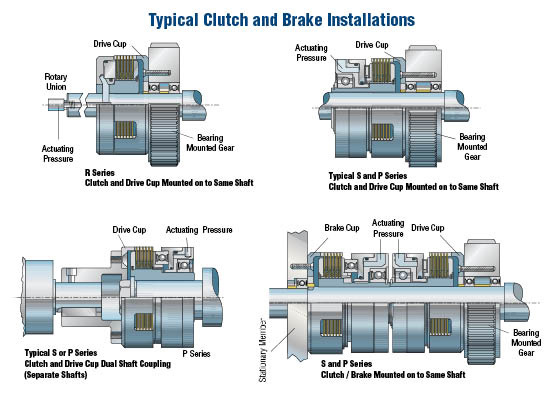

The R series design provides maximum torque within a small envelope. In the R Series design, the piston and actuating cylinder, which is integral with the mounting hub, rotate. Bearings are not required. The shaft on which the hub mounts is rifled and cross drilled to provide passage for the actuating media. A press fit or cap seals are necessary to prevent media pressure loss due to seepage past the hub and shaft interface.

P Series

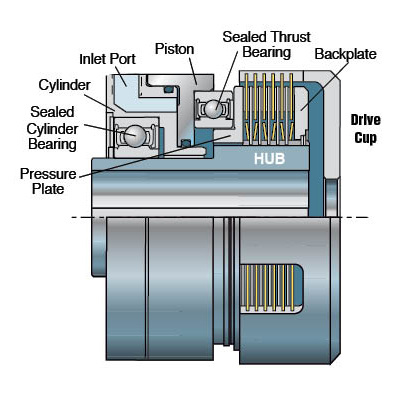

The P series design is similar to the S series, which is designed for wet operation. The difference between the two models occurs in the bearings. P Series bearings are pre-lubricated and sealed and do not require external lubrication. Torque ratings are based on the P Series disc pack operating in dry conditions thus requiring lower actuation pressure to achieve relatively high rates of torque.

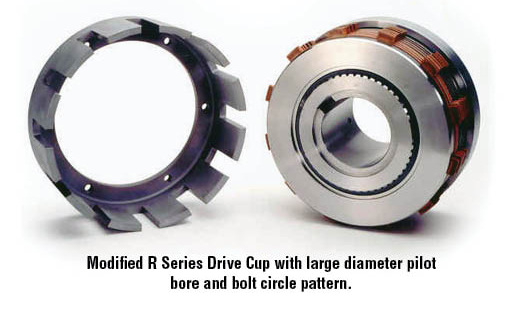

Clutch and Brakes Drive Cups

Logan Drive Cups are manufactured to perform in harsh conditions. Contact surfaces are heat treated to ensure long life. Standard cups are furnished with 1 " and 2 " diameter pilot bores. All models can be furnished with standard lug or gear toothed configurations.