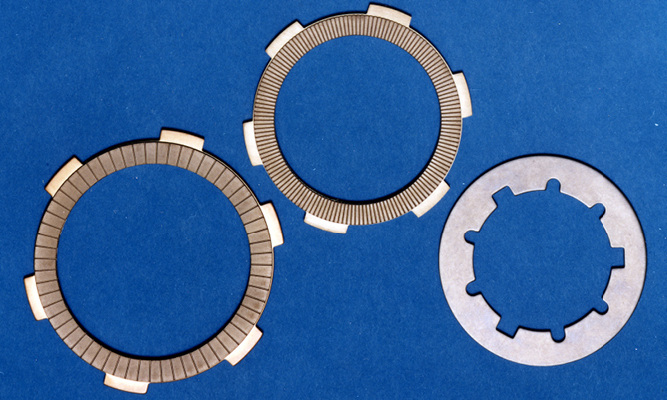

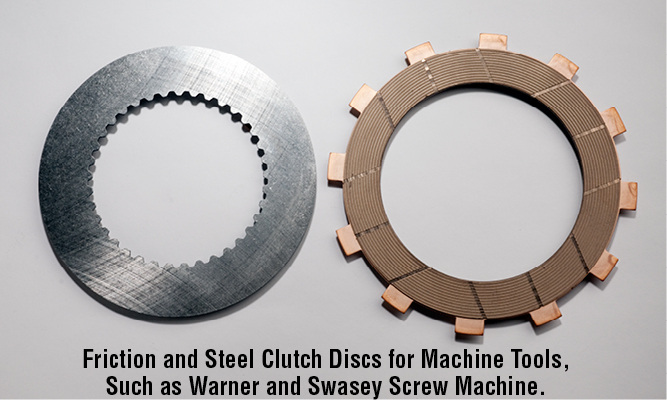

Friction and Steel Clutch Discs

Logan Clutch and Brake Discs

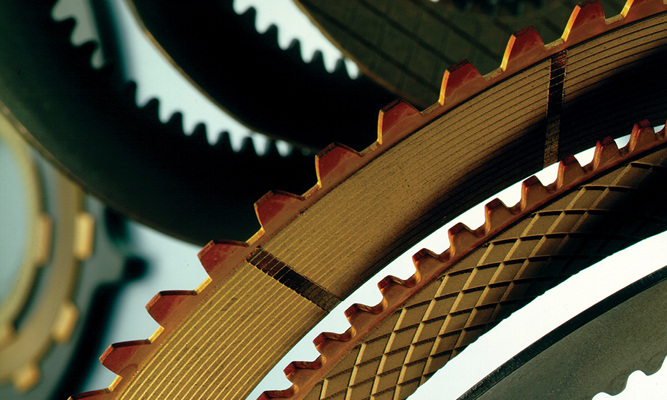

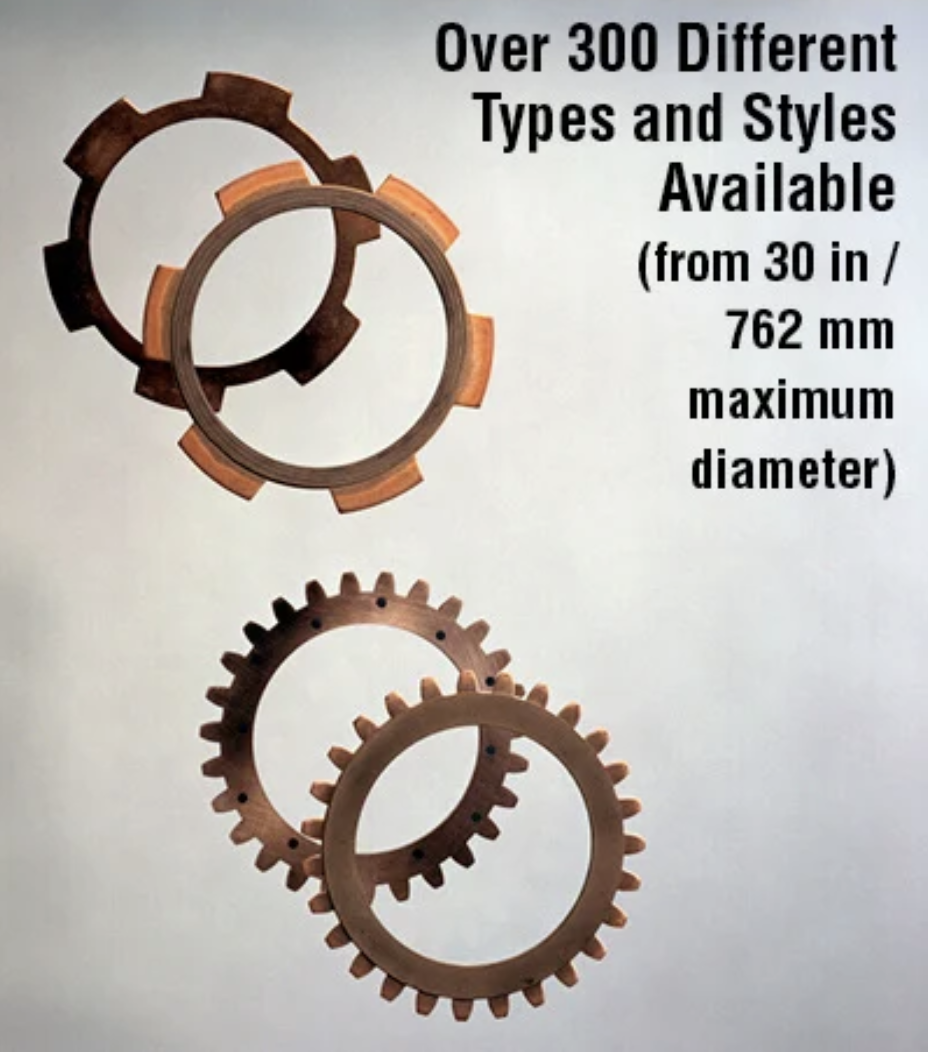

Logan manufactures and stocks a wide variety of both friction faced and high-carbon steel discs for wet or dry clutch and brake applications. The Company also incorporates the latest technology in friction facing material.

In addition to our line of air/fluid actuated Clutches and Brakes, Logan manufactures and stocks a wide variety of friction-faced and high-carbon steel clutch discs for use in a variety of applications. Call our factory for details.

End Uses:

- Marine

- Industrial

- Off-Road

- Mobile Equipment

Advantages:

- Reduce tooling costs with existing Logan tooling

- Improve the quality of your existing friction or steel separator discs with improved friction material coefficients, heat treat specifications and mating disc surface finishes

- Reduce costs and improve delivery by ordering small lots from existing Logan disc inventory

Replacement friction and steel clutch discs for:

- Twin Disc

- Dana / Formsprag / T.B. Woods

- Rockford

- Carlyle Johnson and more

- Ortlinghaus

- Desch

- Stromag

Applications include:

- Mechanical Threading Clutches

- Spindle Stopping Clutches

- Mechanical High Speed and Feed Clutches

- Azimuth Thrusters

- Z-Drives

Logan Groove Pattern Descriptions and Friction Materials

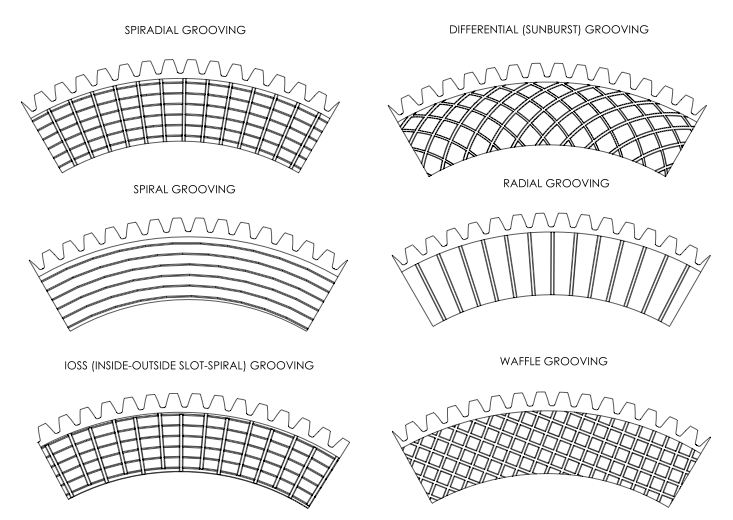

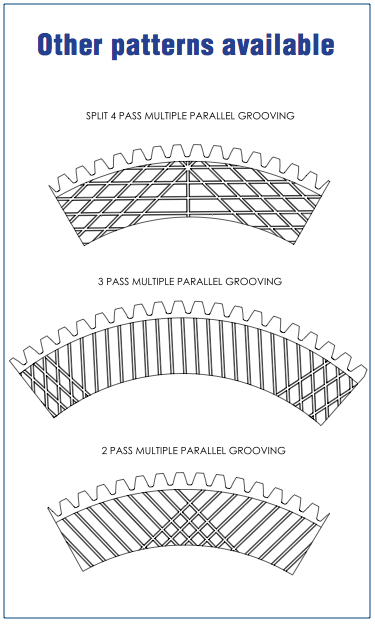

Logan Groove Patterns

Logan groove patterns enable oil to be redirected for fast heat dissipation or contained to allow adequate lubrication in applications where only a mist or spray of oil is available.

Our wide offering of integrally molded groove patterns enable our materials to provide high energy and low wear. Consistent durability, and competitive friction coefficients are additional features when compared to other materials.

Spiradial

Grooving pattern that may be used in wet (with oil) applications where there is limited oil available due to the design of the brake or clutch

Differential

A relatively common pattern, also known as the "sunburst", is generally suitable for ordinary applications where which sufficient oil is available

Spiral

Normally used in sump-type applications where the part is partially submersed in oil

Radial

May be used in either wet or dry applications (depending on the specific design requirements)

Inside-Outside-Slot-Spiral (IOSS)

Complex, high-energy grooving pattern can meet the demands of severe applications where there is very little oil or only a spray of oil available

Plain

A plain lining, with no grooving, can be used for dry brakes or clutches

Logan Friction Materials

Metallic Friction

Our metallic friction materials are composed of a number of base metals. Copper, bronze, iron or iron-bronze bases conduct heat away from the part during use, allowing controlled motion.

Ceramic Friction

Our ceramic friction materials act as insulators, driving heat away from the friction material surface. They also offer low wear, for applications that demand long life and high durability.

Graphitic Friction

The graphite in our graphitic friction materials gives them high energy capacity and low wear, making them ideal for demanding applications.

Contact Our Sales Team

Our Sales Engineers can help you find the exact product or service you need to succeed.