Adding Logan Front of Engine Power Take-off (PTO) Clutches to the SSV Oliver Hazard Perry increases maneuverability, efficiency and safety.

Traditional Sails Equipped with Modern Day Power

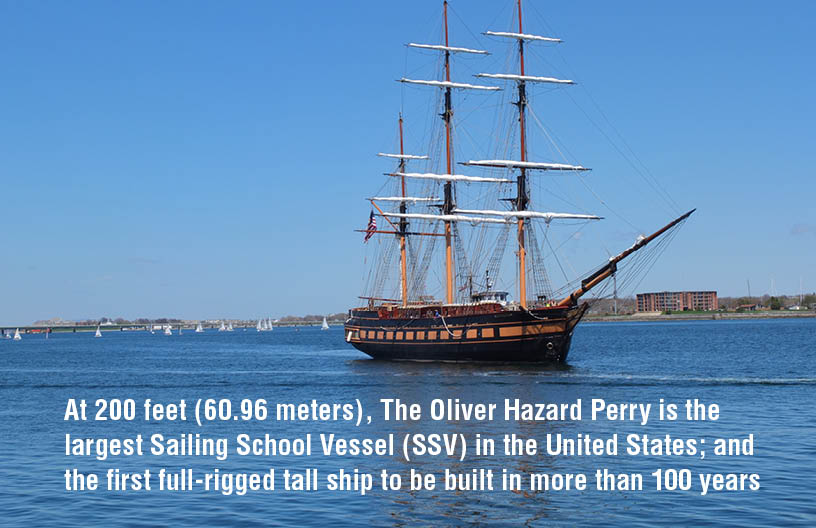

The world’s newest tall ship, the SSV Oliver Hazard Perry, calls Newport, Rhode Island its home. The 200-foot vessel is the largest privately owned tall ship and largest civilian sail training vessel in the U.S. With her three-masted square rig towering 13 ½ stories high, she’s second in size only to the US Coast Guard’s Barque Eagle when compared with any other Tall Ship in America.

The tall ship’s namesake, American Commander Oliver Hazard Perry, won the battle of Lake Erie during the War of 1812 and popularized the phrases, “ We have met the enemy and they are ours” and “Don’t give up the ship.” The massive ship is certified for Ocean Service. The ship has a full-time crew of 17, accommodations for 32 and a day sail capacity of up 85 people. Team building is a key part of the curriculum where students become part of the operating “crew” of the vessel, learn nautical sciences, oceanography and some terrestrial and celestial navigation.

Although the three-masted Oliver Hazard Perry has more than 20 sails and 14,000 square feet of sail area, the steel hulled Perry still depends on its twin Cat C12 series 385 horsepower diesel engines for main propulsion and twin John Deere diesel 4045AFM85 99 kW gensets power the bow thrusters and windlass.

Captain Russell Bostock, the vessels construction superintendent, chose the Deere Genset arrangement. “I was looking for a Tier 3 engine that could handle the continuous duty cycle of a generator. I’ve had good experience with John Deere powered cargo pumps on tank barges and chose to stay with Deere on this project.”

Bostock goes on to explain that the gensets alternate daily, each powering the full electrical load of the vessel.

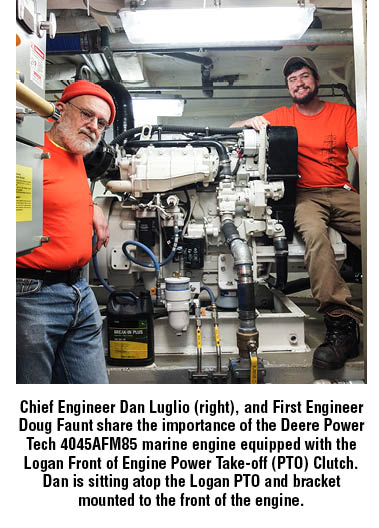

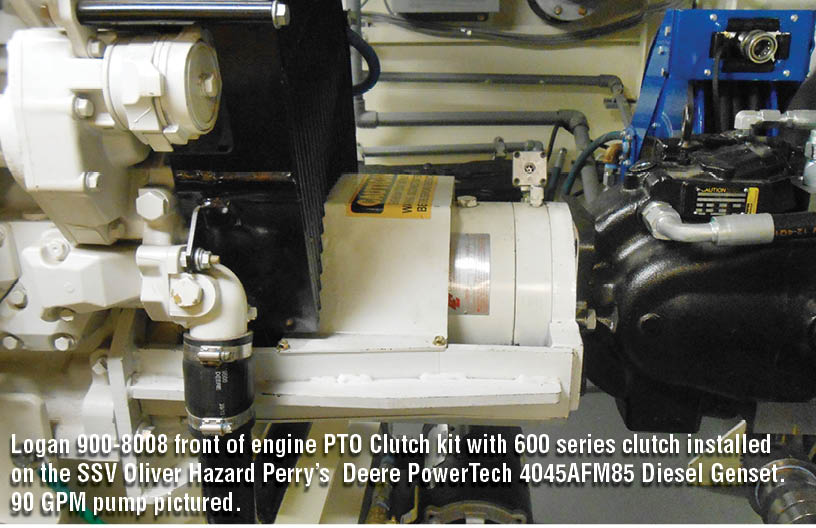

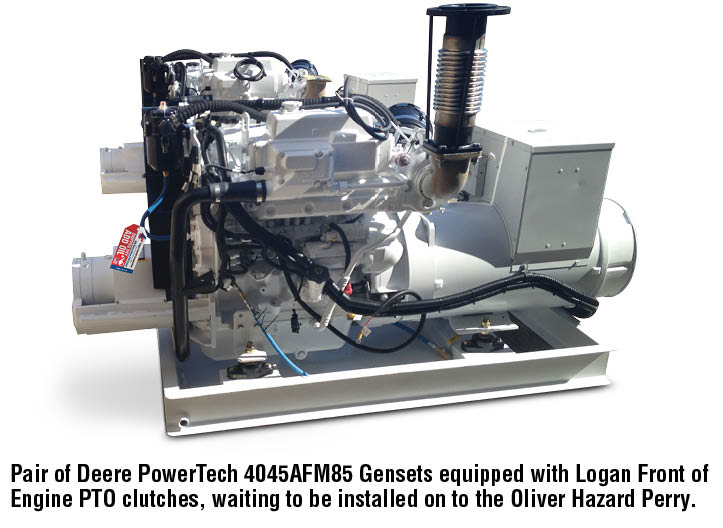

The Deere gensets, supplied by Kennedy Engine, Biloxi, Mississippi, are equipped with Marathon generators on the flywheel housing and Logan Front of Engine PTO Clutches on the front of the engine. Logan 600 series clutches drive 90 GPM hydraulic pumps which control the ship’s bow thrusters (maneuvering) and windlass (to hoist the ship’s anchors and mooring lines), along with other hydraulic powered equipment.

Bostock says, “The ship displaces almost 600 tons (544 metric tons) and each anchor and chain assembly weighs over 6,000 lbs. (2.7 metric tons).” Each Logan PTO clutch, powered by the Deere genset will haul in all of that weight, plus transmit enough torque to independently or together control the ship’s bow thrusters when maneuvering in and out of port – or in close quarters with other vessels.

Tommy Kennedy, owner of Kennedy Engine, has worked with Logan sales engineers on other propulsion and connect-disconnect options for hydraulic pumps that power Z-Drives, bow and tunnel thrusters, deck winches or windlasses.

“If the hydraulic pump drew power from the main engine during docking procedures, or in transit, lower horsepower may mean less maneuverability” – adding to an already potentially dangerous situation. “Having the hydraulics and Logan PTO’s run from the Deere 99-kW gensets, gave ship designers and architects the option to use the front pulley from each of the main engines as power take-offs for the ship’s fire pumps,” says Tommy Kennedy.

The Challenge: Power On-demand

Hydraulically powered bow thrusters allow precise control over the movement of the ship’s bow while maneuvering in and out of small ports, around other vessels, or during docking procedures. The hydraulically powered anchor windlass controls a chain assembly which weighs over 6,000 lbs. (2.7 metric tons). Each genset must power the thrusters and windlass together or independently, when needed and at variable speeds.

The Logan Solution:

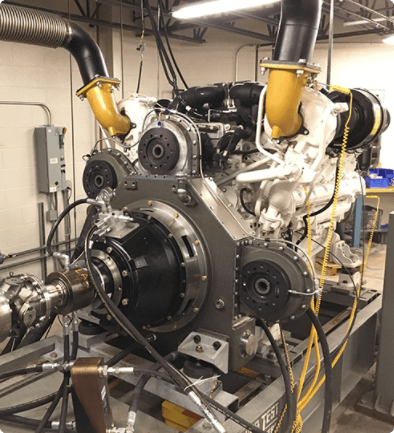

The vessel’s construction superintendent, Captain Russell Bostock, together with ship designers and John Deere Engine Dealer Kennedy Engine chose a Logan engineered Front of Engine Power Take-off (PTO) clutch kit. The Logan front PTO kit is designed to directly mount to most diesel /combustion engine crankshaft pulleys, using a Logan mounting bracket equipped with a Centa torsional coupling and mounting plate to accommodate the simple mounting of any brand of hydraulic pump. The simple compact design fits the front of the engine and enables power on demand to any commercially available hydraulic pump (A through E splined).

The Logan Advantage:

- Logan Power Take-Off Clutch: Compact, self-contained, air or fluid activated, self-adjusting™, abs type certified logan power take-off (pto) clutch .

- Reduced Labor and Installation Costs: The Logan engineered mounting bracket reduces yard installation time and keeps custom fabrication requirements to a minimum.

- Less Torsional Vibration: The engineered bracket mounts directly to the engine, and incorporates a Centa flexible coupling, which further reduces susceptibility to torsional vibration.

- Logan Soft-StartTM Manifolds and Power Packs: Logan offers complete 12 VDC or 24 VDC activated manifolds and power packs to engage the Logan PTO remotely from any location on the vessel – engine room, bridge or wheelhouse.

Two Gensets with Logan Front mount kits were ordered and installed on the vessel to control the large 90 GPM pumps. The clutches allowed the pumps to engage remotely from the same area as the Genset Controls and work only when needed. A second hydraulic valve was installed to control the bow thruster and windlass separately.

Since the hydraulic pumps are now engaged on demand, there’s less wear and tear on the pumps; less fuel is consumed which lowers emissions and less noise in the engine room occurs. The crew especially appreciates less noise because bunks tend to be near the engine room.

Bostock says “From a reliability and maintenance perspective, the Logan Front of Engine PTO gave us the option we were looking for to hydraulically control the windlasses and thrusters. The alternative would have been to use electrically controlled windlasses and thrusters which would have required extensive wiring, and circuit protection devices. We know we made the right decision.”

The Logan Advantage:

Fewer engines to buy and maintain = Faster return on investment (ROI)

Installing and operating a hydraulic pump (on demand via a Logan clutch) from the front of an auxiliary engine / genset allows, in this situation, the use of the front pulley of each of the main engines to be used as power take offs for fire pumps, eliminating the need for an additional, auxiliary engine.

Convenient operation = Increased efficiency and safety

Logan’s complete hydraulic and pneumatic manifolds are activated by 12 or 24 volt DC power, enabling the controls to engage the clutches from anywhere on the vessel.

Reduced wear and tear = Lower maintenance costs

Hydraulic pumps no longer run continuously, and operate only when needed. Pumps require less frequent routine maintenance and replacement.

Less fuel consumption = Saves time and money

Less fuel is consumed since pumps run only when required, instead of running continuously during genset operation. This saves fuel, refueling time and expense.

Reduced emissions = Cleaner environment

Engines running under lower stress and strain reduce fuel consumption, which leads to lower emission levels.

Logan Clutch Corporation is proud to be a part of history. The SSV Oliver Hazard Perry is the first American tall ship to be built in more than 100 years and is the largest civilian Sailing School Vessel in the US.

The SSV Oliver Perry:

The SSV Oliver Perry:

- Carries the name of American Commander Admiral Perry who won the battle of Lake Erie during the War of 1812 and is known for the phrase, “Don’t give up the ship”

- Includes 7 miles of rope, 160 belaying pins, 20 sails and 14,000 sq. ft of sail

- Is classified as an ocean-going full-rigged ship

- At 200 feet / 60.96 meters, the SSV OHP is second in size only to the US Coast Guard’s Barque Eagle (295 feet / 89.916 meters)

- Conducts educational activities. All who sail aboard are crew and take active roles in sailing the ship safely

- Meets and exceeds all USCG and ABS safety requirements for a ship of her size

- Ports in Newport, Rhode Island