Overview

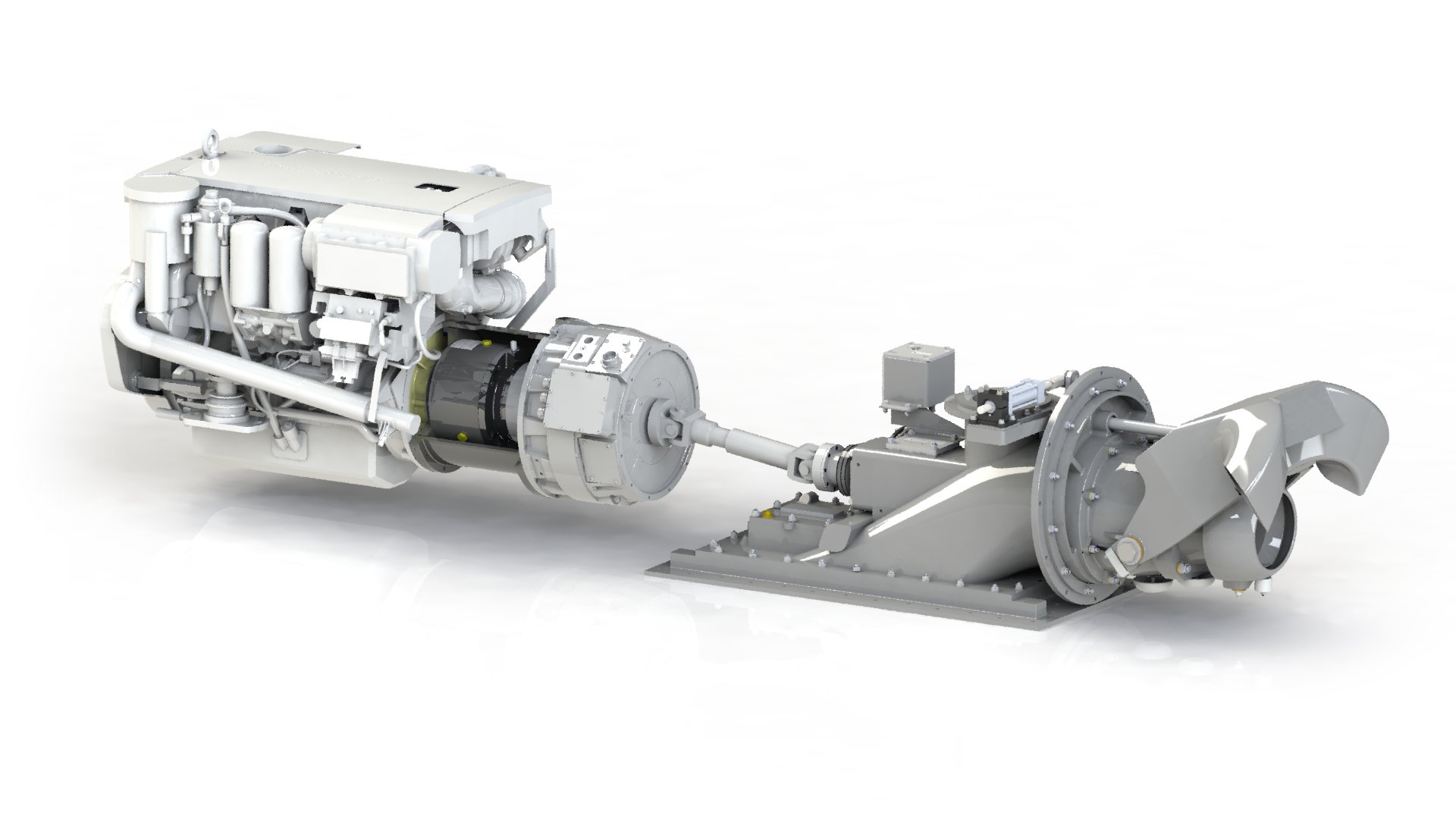

Public safety agencies are being asked to reduce emissions, fuel consumption, and diesel engine idle time without compromising mission readiness. This hybrid marine propulsion case study documents an approach that prioritizes mechanical simplicity and serviceability: an in-line diesel–electric hybrid driveline that uses a disconnecting direct drive PTO clutch to mechanically couple and decouple power sources.

Operating Profile

The vessel must support low-speed patrol, docking, and surveillance using electric propulsion while preserving immediate access to diesel power for pursuit, emergency response, and high-speed transit.

System Components

This hybrid driveline integrates the following named components:

-

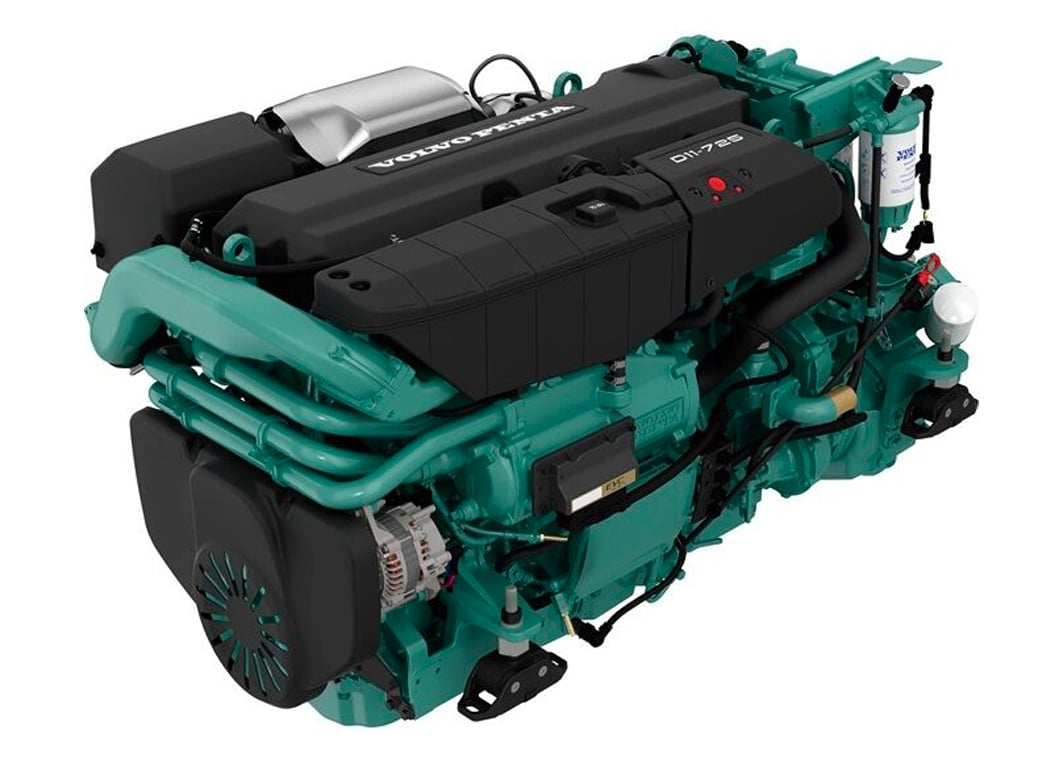

Volvo Penta D11 diesel engine (625 HP class) prime mover for high-speed response and extended-range operation

-

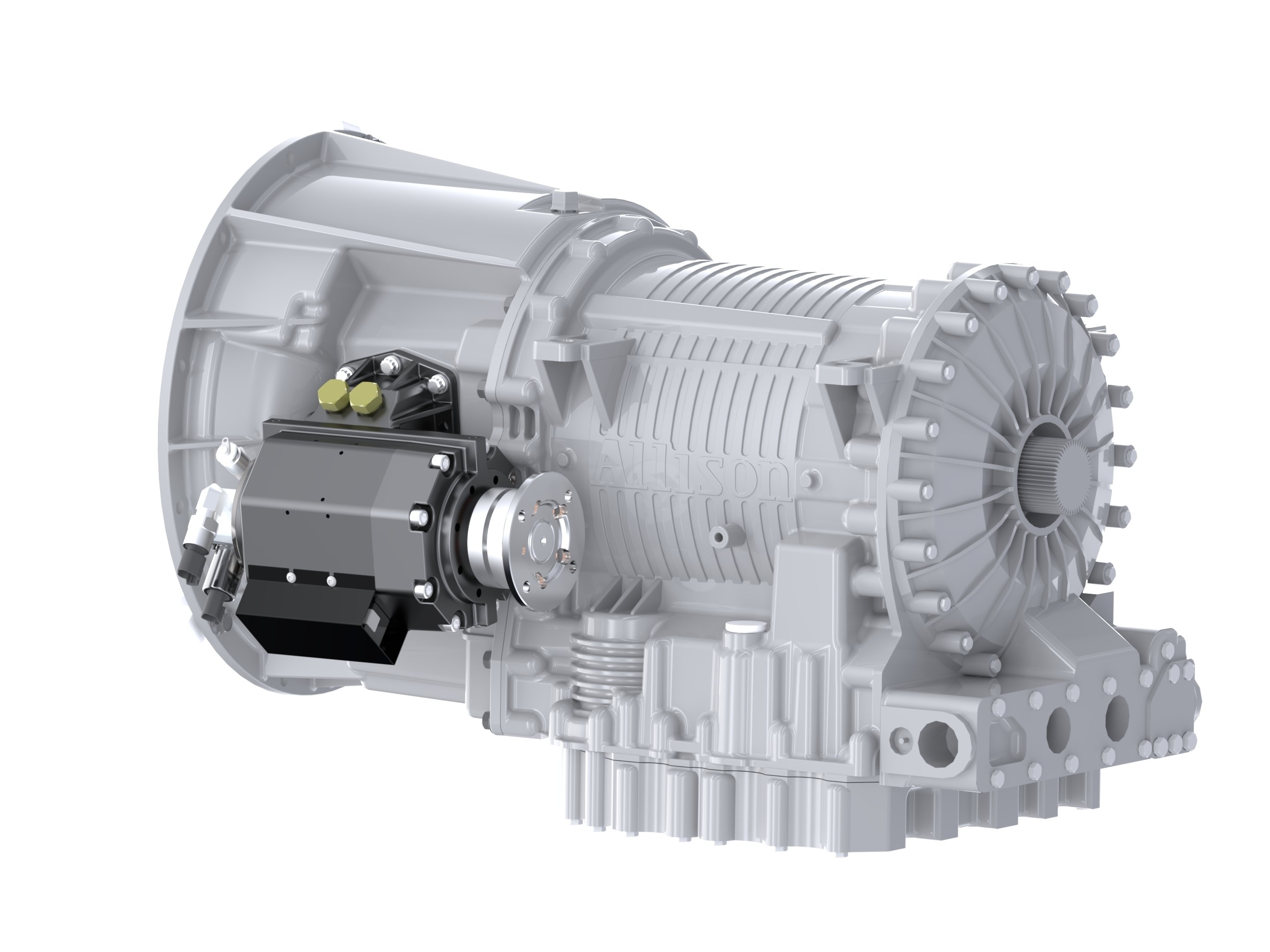

Logan 2200 Series self-contained direct drive PTO clutch — mechanical coupling/decoupling device between diesel engine and electric motor

-

Danfoss EM-PMI300-T310 electric motor — in-line electric propulsion and generation

-

Hamilton Jet waterjet — final propulsion unit for shallow water and maneuverability

Driveline Architecture: In-Line Diesel–Electric Hybrid Waterjet Propulsion

Each propulsion line is arranged in-line: the Volvo Penta D11 diesel engine is aligned with the Danfoss EM-PMI300-T310 electric motor, and the output drives a Hamilton Jet waterjet. Between the diesel engine and electric motor is the Logan 2200 Series direct drive PTO clutch.

This configuration preserves a straight-through torque path while enabling mechanical decoupling. Eliminating a power-splitting transmission reduces complexity, lowers parasitic losses, and simplifies alignment and long-term service in a marine environment.

How the Hybrid Driveline Works

The Logan direct drive PTO clutch provides the mechanical disconnect required for hybrid operation:

-

In electric-only mode, the clutch disengages to isolate the diesel engine. This prevents continuous engine drag and allows the electric motor to drive the Hamilton Jet waterjet independently.

-

In diesel mode, the clutch engages to provide a rigid, high-torque mechanical connection capable of transmitting the diesel engine’s output through the electric machine to the waterjet.

-

In combined mode, diesel power is available with electric assist to improve acceleration and upper-end performance.

-

In diesel-driven charging mode, the diesel engine can back-drive the electric motor as a generator, replenishing battery reserves without a dedicated generator set.

This approach uses mechanical coupling and decoupling instead of torque blending through a complex transmission, which improves predictability and supports robust load handling for emergency response and law enforcement duty cycles.

Logan Direct Drive PTO Clutch: Technical Details

The Logan 2200 Series PTO clutch used in this hybrid driveline is a hydraulically actuated, wet multi-disc clutch designed for high torque transfer in a compact, enclosed assembly.

Key ratings and design features include:

-

Torque capacity: 2,200 lb-ft (3,000 Nm), continuous rating, with a 3,300 lb-ft (4,475 Nm) peak static rating (33% factor of safety)

-

Maximum operating speed: up to 2,300 RPM

-

Enclosed, corrosion-resistant housing: does not require external guarding

-

Self-adjusting disc pack: allows for consistent, smooth connect-disconnect engagement characteristics over service life

-

Metered pneumatic or hydraulic soft-start system: supports controlled engagement at engine idle or elevated RPMs and helps minimize shock loads into the electric motor, waterjet, and downstream driveline components

-

Optional manual “get-home” engagement capability to support degraded-mode operation if pneumatic or hydraulic control is disrupted.

-

American Bureau of Shipping (ABS) Type Approved In hybrid marine propulsion applications, controlled engagement is important for reducing transient torsional loads during mode transitions and maintaining driveline durability under repeated maneuvering and response cycles. The Logan 2200 Series clutch is ABS Type Approved and is sized so the 2,200 lb-ft continuous torque remains within the ABS driveline design safety margin (1.7×, as applicable). In addition, a 3,300 lb-ft peak torque capability provides further margin for short-duration transients, rapid throttle changes, and repeated engagement events.

Application-Specific Configuration for Hybrid Integration

For this hybrid patrol vessel driveline, Logan supplied a custom-configured direct drive PTO clutch assembly designed to mount between the diesel engine and electric motor using standard interfaces.

The integration package includes:

-

SAE #2 engine housing mounting plate and spacer

-

SAE 11.50-inch flywheel coupling with SAE F output spline

-

Clutch housing with SAE #4 output mounting plate for Danfoss electric motor installation

-

Spline interfaces: SAE F input spline and DIN 5480 output spline to the motor

-

Pneumatic soft-start package: 120 PSI, 24 VDC

This modular configuration simplifies installation and alignment and supports future updates as battery and electric motor technologies evolve.

Electric Propulsion and Energy Management

The Danfoss EM-PMI300-T310 electric motor, mounted in-line via the Logan PTO clutch, supports low-speed electric propulsion for patrol, docking, and surveillance. Energy is supplied by marine battery systems (for example, Corvus Energy battery technology), enabling up to approximately two hours of electric-only operation at about five knots, depending on duty cycle and operating conditions.

In diesel operation, the driveline enables the Volvo Penta D11 to drive the electric motor as a generator, replenishing batteries without adding a dedicated generator set. This reduces system weight and complexity while maintaining flexible operating modes.

Hamilton Jet Integration and Vessel Control

Propulsive power is delivered to Hamilton Jet waterjets, selected for:

-

Shallow-water capability

-

High maneuverability within shallow conditions

-

Reduced risk from underwater obstructions

Waterjets complement hybrid operation by supporting precise low-speed handling under electric power. Control systems such as Hamilton AVX Express can provide joystick maneuvering, jet anchoring, and remote piloting capability, improving handling in confined waterways and during docking or boarding operations.

User Benefits:

Benefits for Mechanical & Marine Engineers

This in-line hybrid driveline architecture provides a straight-through torque path and avoids power-splitting transmissions, which can simplify integration and service. Key engineering benefits include reduced parasitic losses, easier alignment, and a mechanical disconnect that eliminates continuous engine drag during electric-only operation. The modular arrangement also improves access for maintenance and supports future component upgrades.

Benefits for Operators & Marine Crews

Electric-only propulsion enables low-speed patrol, docking, and surveillance with reduced noise and emissions. Diesel propulsion remains immediately available for pursuit and emergency response. Waterjet propulsion and advanced controls improve maneuverability in tight quarters, and electric operation reduces noise and vibration for improved crew comfort during extended patrols.

Benefits for Fleet Managers & Procurement Teams

Hybrid operation can reduce fuel consumption and diesel engine idle hours, which lowers operating cost and may reduce wear associated with prolonged idling. The architecture relies on proven diesel engines and mechanical PTO technology, supporting maintainability and lifecycle planning. The system also aligns with emissions and grant funding objectives while remaining adaptable to evolving battery and electric motor technologies.

Frequently asked questions:

Why use a direct drive PTO clutch instead of a hybrid gearbox or power-splitting transmission?

A disconnecting direct drive PTO clutch preserves a straight-through torque path while providing full mechanical decoupling in electric-only mode. This avoids continuous engine drag and reduces drivetrain complexity, parasitic losses, alignment burden, and service requirements compared with power-splitting architectures.

How does electric-only operation work in this driveline?

In electric-only mode, the Logan PTO clutch disengages to isolate the diesel engine. The Danfoss EM-PMI300-T310 electric motor then drives the Hamilton Jet waterjet independently for low-speed patrol, docking, and surveillance.

Can the diesel engine recharge the batteries without a dedicated generator?

Yes. When operating in diesel mode with the driveline engaged, the Volvo Penta D11 can back-drive the electric motor as a generator to replenish onboard battery reserves without adding a dedicated genset.

What clutch ratings matter for this hybrid marine application?

For hybrid marine duty, the clutch must support continuous transmitted torque, peak static (holding) torque, and the required operating speed. The Logan 2200 Series clutch delivers 2,200 lb-ft (3,000 N•m) continuous duty, a 3,300 lb-ft (4,475 N•m) peak static rating (33% factor of safety), and operation up to 2,300 rpm, using a hydraulically or pneumatically actuated wet multi-disc design with an enclosed corrosion-resistant housing and a self-adjusting wet disc pack.

Technical Summary:

This hybrid marine driveline uses an in-line diesel–electric architecture integrating a Volvo Penta D11-625 HP diesel engine, a Logan 2200 Series self-contained direct drive PTO clutch, a Danfoss EM-PMI300-T310 electric motor, and a Hamilton Jet waterjet. The disconnecting PTO clutch provides mechanical coupling and decoupling between diesel and electric power sources, supporting diesel-only propulsion, electric-only propulsion, combined boost, and diesel-driven charging without a power-splitting hybrid transmission.