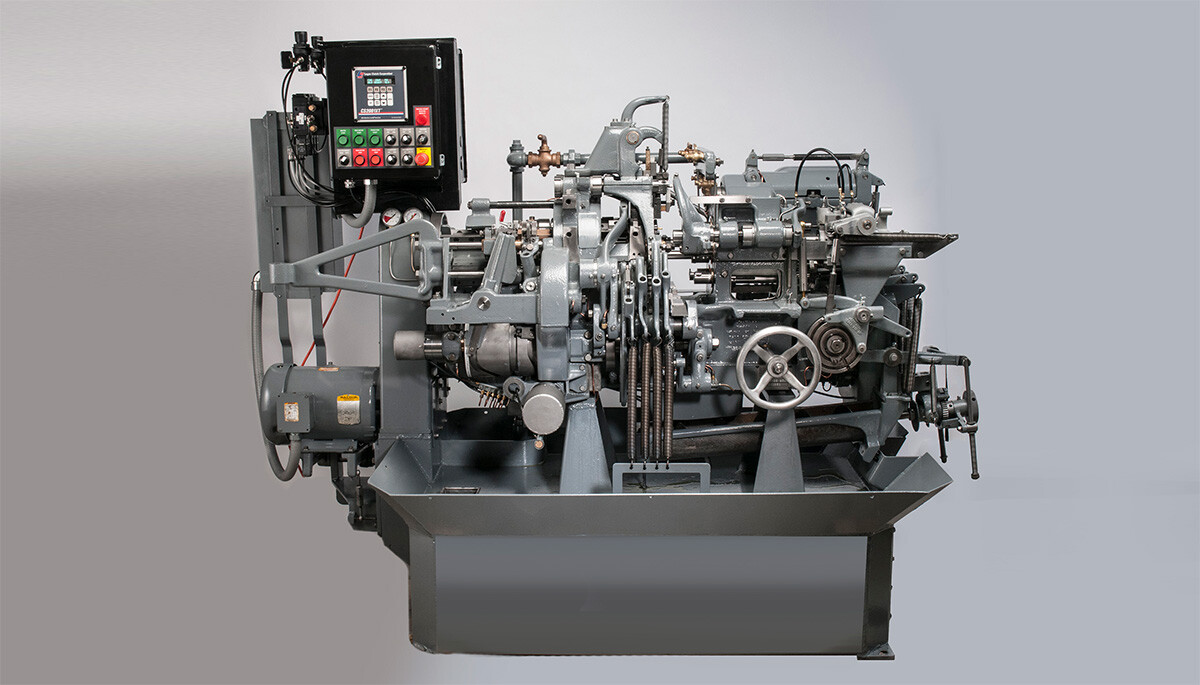

If you're running a Davenport Model B screw machine, you know how crucial efficiency, precision, and reliability are to keeping up with production demands. The challenge? Many older machines still rely on mechanically actuated clutches from the 1940s, which can slow down operations and require constant adjustments.

At Logan Clutch, we offer modern clutch solutions that seamlessly integrate with your Davenport Model B, boosting output by 10-20% or more while reducing maintenance. By replacing outdated components with our air-actuated, self-adjusting Logan clutches™, you can produce more parts per hour, per day, and per week—without increasing floor space or labor costs.

Why Upgrade? The Problem with

Old-Style Mechanical Clutches

Traditional high-speed and feed clutches, roll clutches, band brakes, linkages, and lever arms wear out over time, leading to:

Inconsistent Speed Changes

Slower transitions reduce efficiency and cycle time accuracy.

Frequent Maintenance & Adjustments

Manual tuning is required to prevent slippage and keep the machine running.

Lost Productivity

Even a 0.2-second variation in cycle time can reduce productivity by over 10%—nearly 200 parts per hour.

Our Logan Clutches™ eliminate these inefficiencies, ensuring smooth speed transitions, faster cycle times, and reduced downtime.

How Logan Clutch Enhances Your Davenport Model B

✅ Faster, More Reliable Speed Transitions with Hi-Lo Retrokits™

Our Hi-Lo Retrokits™ enable seamless high-to-low speed transitions, improving consistency, accuracy, and repeatability. Since Logan clutches™ are self-adjusting, they eliminate clutch slippage—so you never have to stop for manual adjustments.

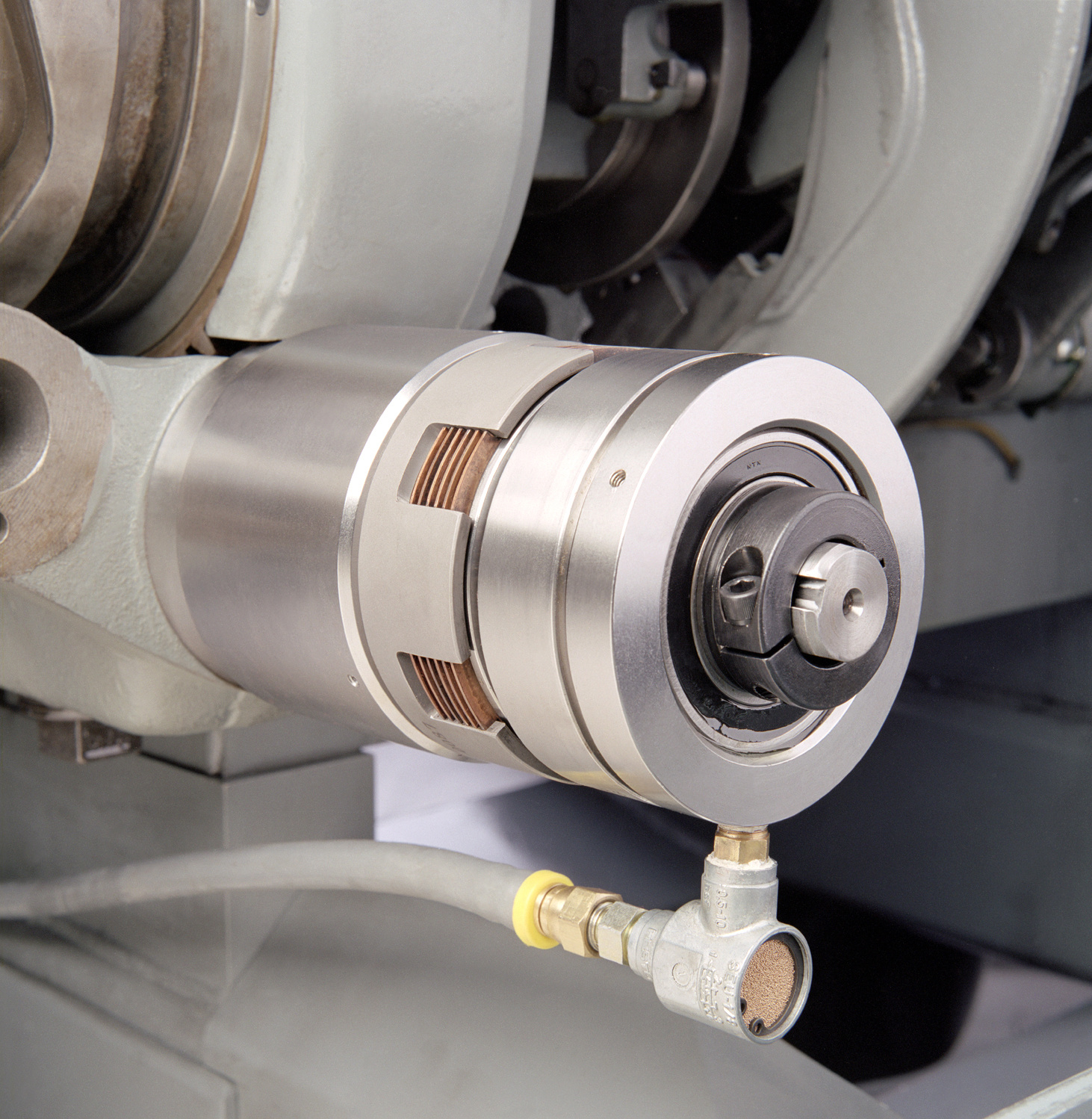

✅ Achieve Uniform Tap Depths with Logan Air Threading Clutches™

Logan Air Threading™ Clutches have become the industry standard, replacing legacy mechanical clutches. These clutches:

- Ensure uniform tap load, prolonging tap life and reducing tooling costs.

- Minimize tool changes, saving valuable hours on high-volume production runs.

- Deliver consistent, precision machining, eliminating inconsistencies in tap depth.

✅ Automate with Precision

For manufacturers looking to integrate automated bar loaders, Logan clutches™ provide precise control through a quick-stop power-applied brake. This prevents machine coasting and ensures accurate stock-loader positioning.

If a fault or start interrupt occurs, our system instantly stops the machine, making Logan clutches™ the perfect choice for automated operations.

Logan CS2001XTP™ Controls: Take Productivity to the Next Level

For even greater efficiency, pair Logan clutches™ with our Logan CS2001XTP™ Controls, which offer:

- Dialed-in cycle times for optimized performance.

- Real-time parts and tool counting to track production efficiency.

- Thread check functionality to ensure precision machining.

With these controls, you reduce human error, minimize downtime, and maximize machine output.

Real-World Results: The Power of Logan Clutch Upgrades

What does this mean for your bottom line?

If your planned cycle time is 2.0 seconds, even a small variation of 0.2 seconds due to improper clutch adjustment can cut productivity by 10% or more.

With Logan Clutch’s precision-engineered solutions, you can achieve guaranteed cycle time repeatability over millions of parts—without stopping for mechanical adjustments.

If your machine completes cycles in under 50 hundredths, our system allows you to fine-tune speed shift points for even faster production.