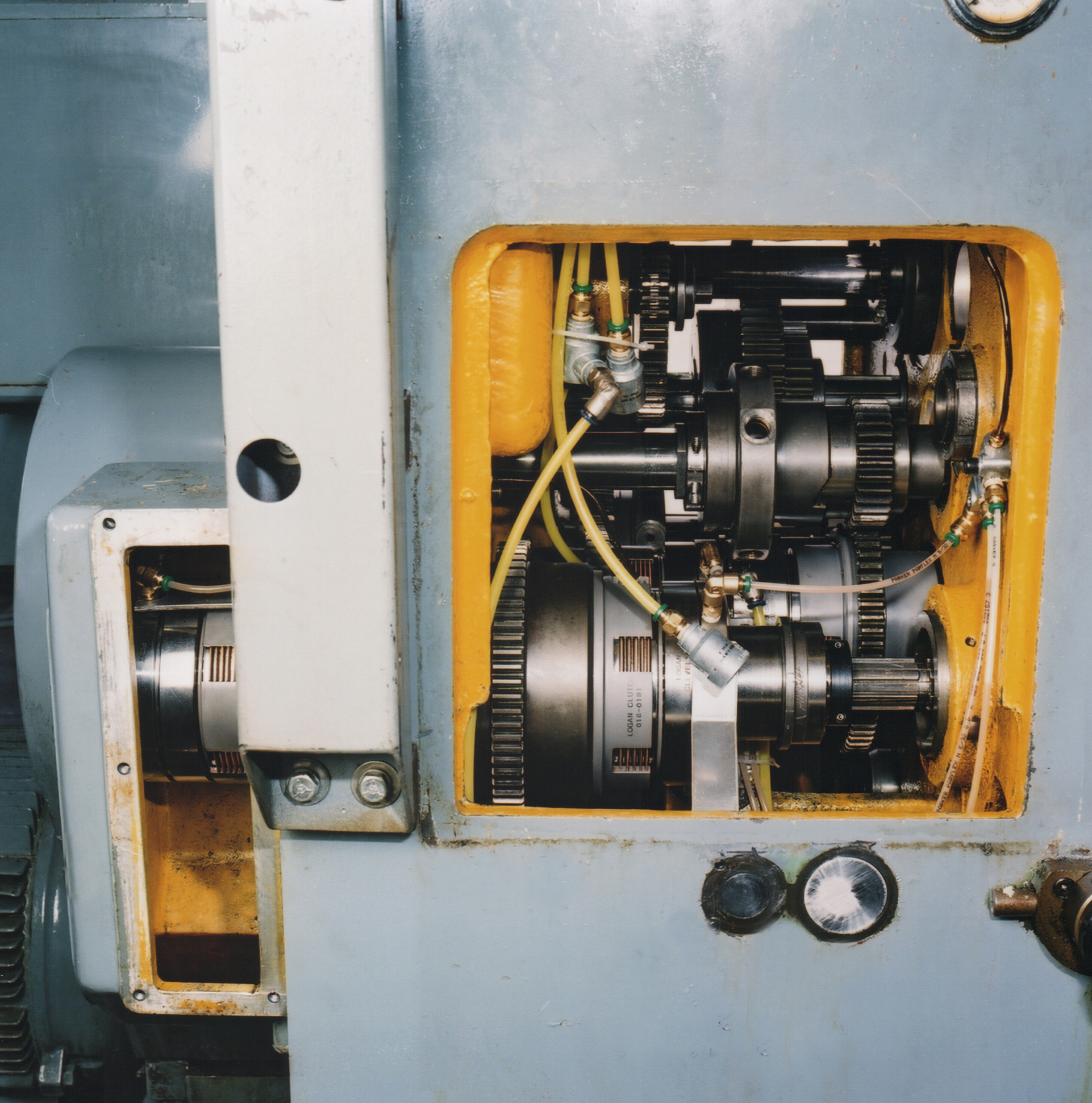

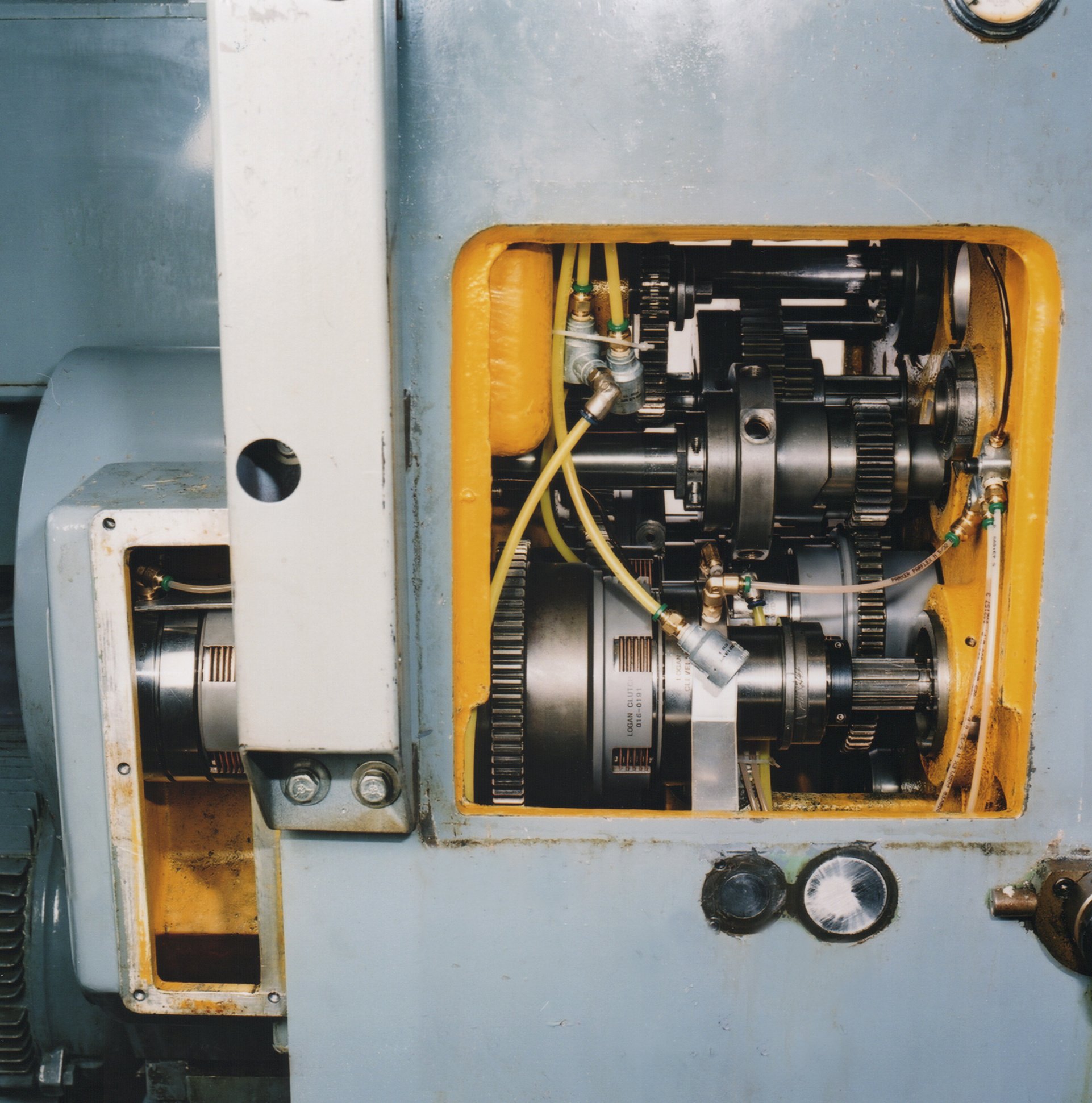

For over 30 years, Logan Clutch has been helping manufacturers boost efficiency, reduce downtime, and enhance precision in their Wickman screw machines. Whether you’re running early or late-model Wickman machines, our Air Threading™ Clutches, Hi-Lo Retrokits™, Pick-off Drives, and Advanced Controls can increase your daily and weekly output by 10-20% or more—without adding more machines, operators, or floor space.

Why Upgrade Your Wickman Screw Machines?

Many Wickman machines still rely on outdated mechanical clutches that slow down production and require frequent maintenance. With Logan Clutch’s air-actuated, self-adjusting solutions, you can:

✅ Eliminate clutch slippage for more reliable operation.

✅ Reduce maintenance and adjustments—no more worn-out linkages, bands, or pins.

✅ Increase productivity by minimizing idle time and improving speed transitions.

✅ Improve machining precision with consistent, repeatable cycle times.

Logan Air Threading Clutches: Achieve Consistent Tap Depths

One of the biggest challenges in tapping operations is maintaining uniform thread depth across millions of parts. Logan Air Threading Clutches™ provide smooth and positive engagement, ensuring:

- Consistent Tap Depth – No variations across high-production runs.

- Prolonged Tap Life – Less wear means fewer tool changes and lower costs.

- Up to 200% More Tapping Torque – Expand your machine’s capabilities to handle more demanding jobs.

- Easy Installation – Works with most Wickman machines without major modifications.

Bonus:

Our self-adjusting disc pack eliminates slippage, ensuring cycle time repeatability over millions of parts.

Logan Hi-Lo Retrokits™: Faster Cycle Times & Smoother Speed Changes

Traditional Wickman clutches struggle with high-to-low speed transitions, leading to inefficiencies. Our Hi-Lo Retrokits™ solve this by:

✔ Reducing idle time between speed changes

✔ Providing crisp, repeatable engagement for better accuracy

✔ Preventing machine coasting with a quick-stop power-applied brake

✔ Eliminating manual clutch adjustments—no disc pack tuning required

Real-World Impact:

Even a 0.2-second variation in cycle time can reduce productivity by 10% or more. With Logan Clutches, you guarantee repeatability, maximizing output without costly downtime.

Logan Pick-off Drives: Minimize Secondary Operations & Improve Efficiency

In today’s fast-paced manufacturing world, eliminating secondary operations is critical. That’s where our Single and 2-Speed Stop and Drop™ Pick-off Drives come in.

- Brake-Stop Technology – Stops the pick-off spindle before the collet opens, preventing nicks, marks, and lost parts.

- Enhanced Reliability – Dead spindle ejection ensures consistent part release, reducing machine lockups.

- 2-Speed Option – Up to 45% faster RPM for improved back machining and drilling.

- Retrofits Existing Systems – Works with both OEM and aftermarket air pick-off attachments.

Result:

Faster part ejection, reduced errors, and increased efficiency.

Logan CS2001XTP™ Controls: Precision & Productivity at Your Fingertips

The CS2001XTP™ Control System brings modern technology to your existing Wickman screw machines. With features like Tool Counters, Thread Check, Machine LockUp™ Detection, and Stock Load Positioning, this system reduces setup time and maximizes efficiency.

Key Benefits:

- Machine LockUp Detection – Minimizes tool crashes and damage.

- Cycle Time Optimization – Program speed shifts in 1-degree increments.

- Real-Time Data – View cycle times, part counts, run-time, and machine positioning.

- Thread Check – Stops the machine before tap failure, reducing scrap.

- Wi-Fi Capabilities – Easy integration with ERP systems for seamless data tracking.

Why It Matters:

By automating these processes, you reduce human error, speed up production, and extend machine lifespan.

Why Choose Logan Clutch?

In today’s manufacturing industry, every second counts. Logan Clutch helps you:

✔ Maximize your existing machine efficiency—no need for costly new equipment.

✔ Reduce maintenance downtime with self-adjusting, long-lasting clutches.

✔ Increase profitability by producing more parts in less time.

Upgrade Your Wickman Screw Machines Today!

📞 Let’s Talk! Contact our team at Sales@loganclutch.com to schedule a consultation. We’ll help you find the best solution to optimize your Wickman screw machines.