Logan PTO clutches for a simple, immediate reduction in fuel consumption, operating costs, and greenhouse gas emissions.

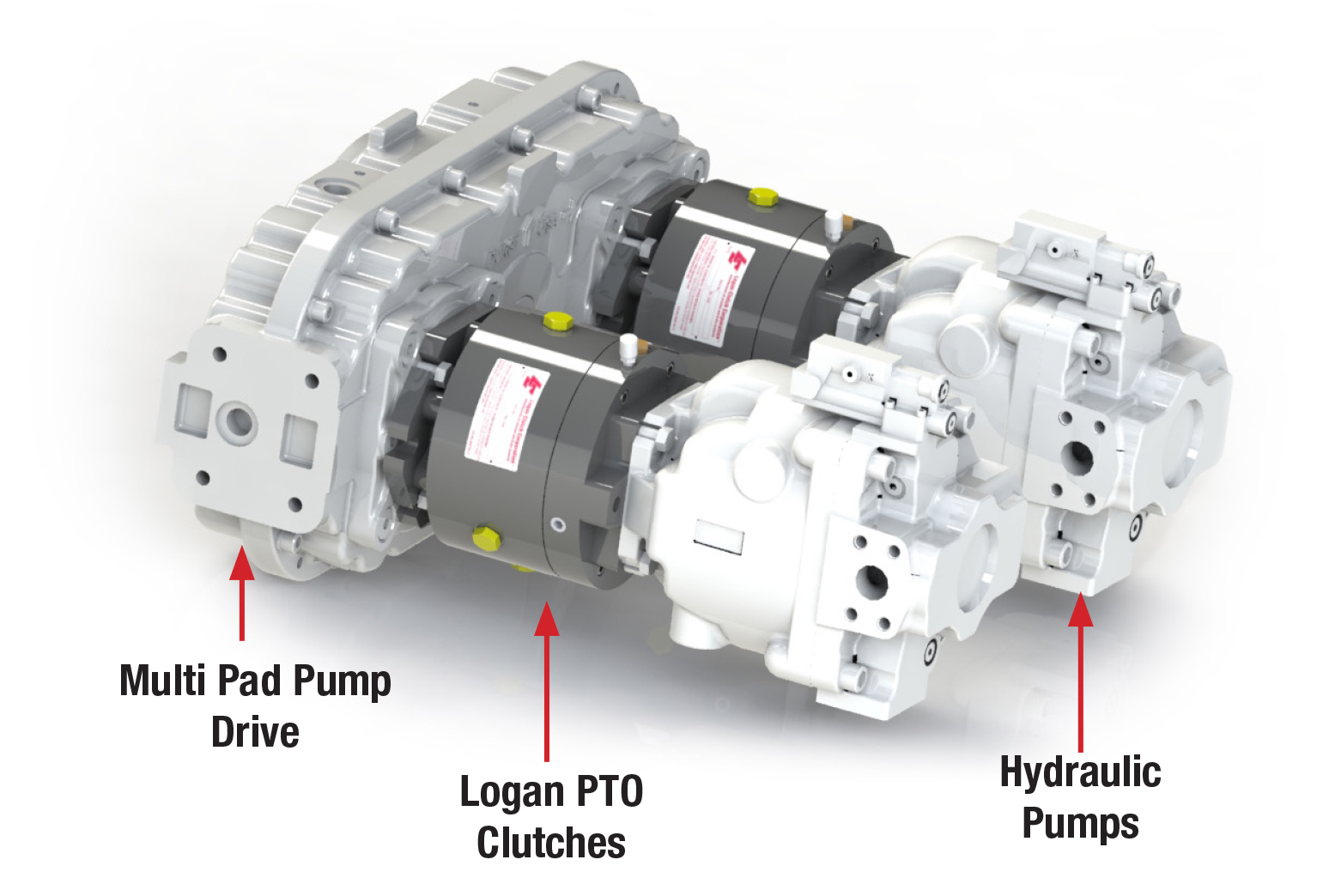

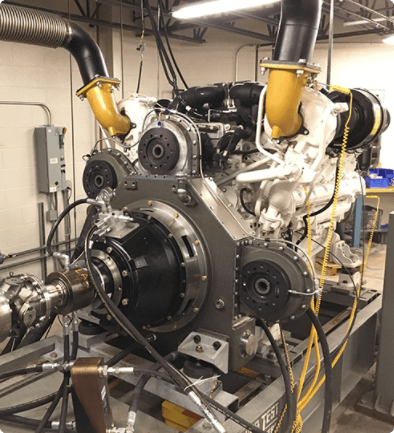

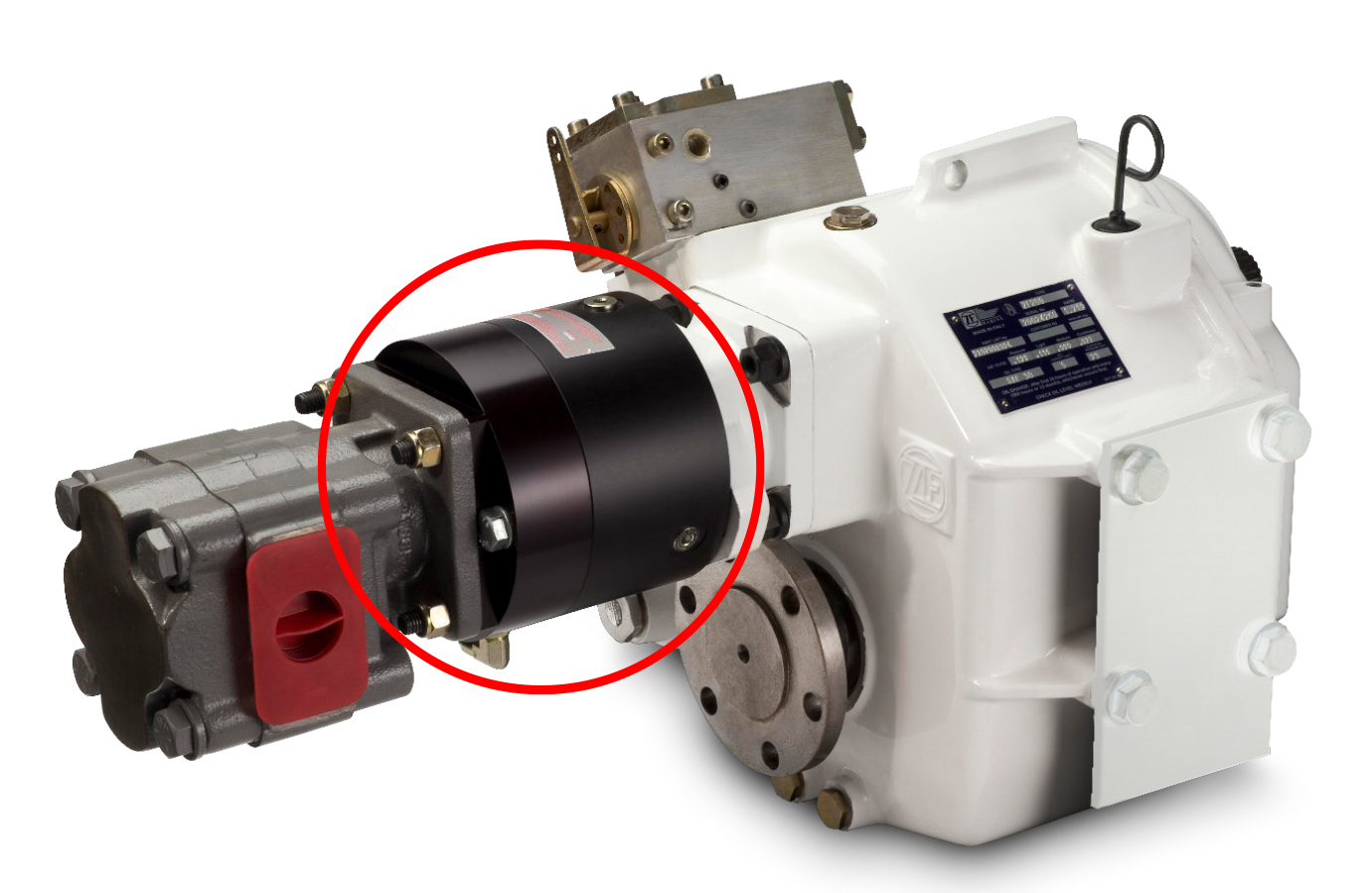

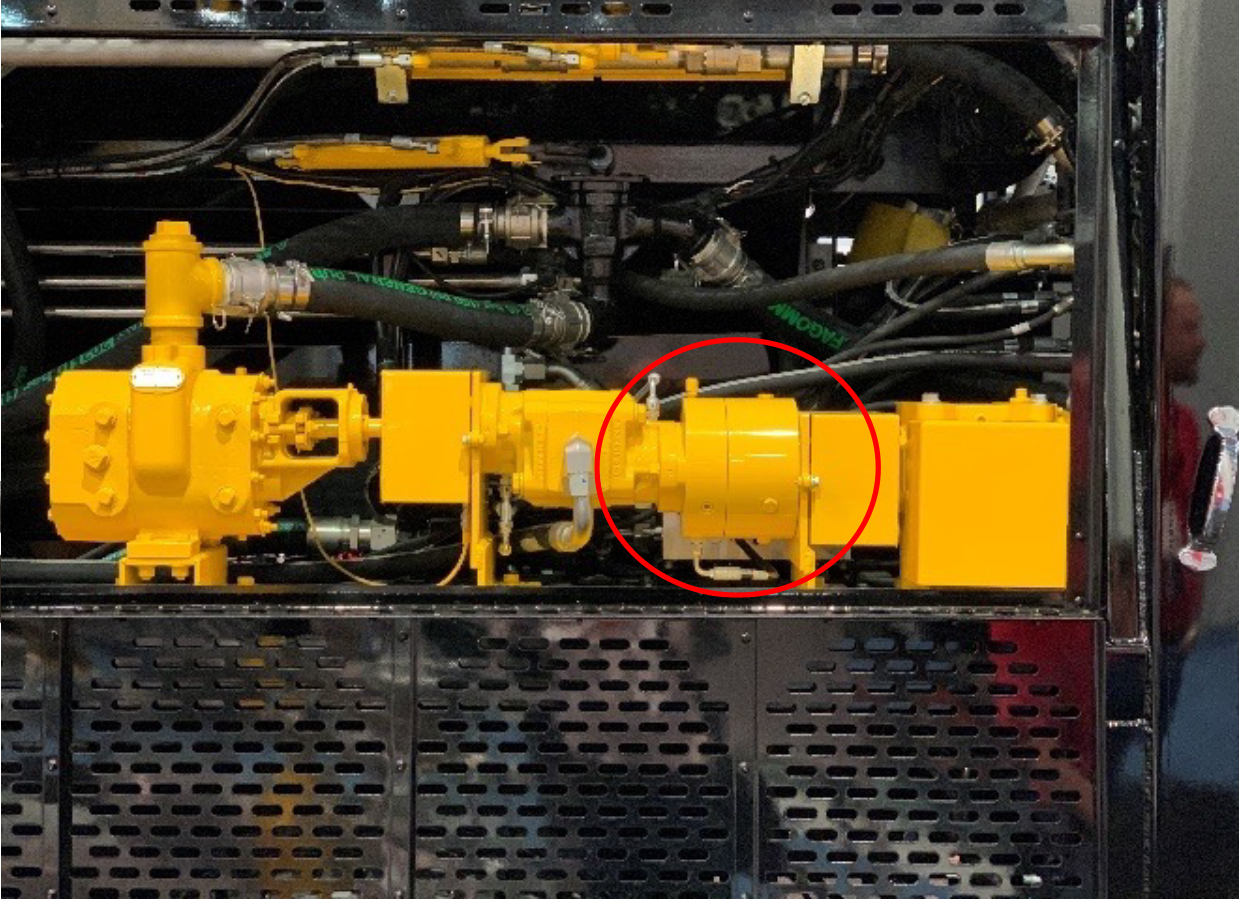

Logan Direct Drive Power Take-off (PTO) clutches are designed to mount between the main or auxiliary live PTO of your engine and attachment, i.e. auxiliary drive, single or multiple pump drive, hydraulic pump, or attachment. For example, Logan PTOs are an effective and reliable solution for applications where hydraulic pumps are used on-demand, or in continuous, intermittent duty situations.

How They Work:

Logan PTO Clutches are hydraulically or pneumatically actuated, and self-contained within a rugged, lightweight corrosion resistant housing, that does not require external shielding. A splash oil bath provides lubrication to the multiple disc, self-adjusting, wet clutch pack. Pressurizing the cylinder forces the piston to clamp and lock the friction and separator discs. When pressure is removed, release springs separate the separator discs, which provides a running clearance between discs when the clutch is disengaged. In the event of power disruption, (ABS type approved) manual engagement screws are used to mechanically engage the clutch.

Push-button, or Switch Activated:

Clutches are remotely controlled with an on-off switch located on a helm, dashboard, or control panel – or via a switch on a Logan hydraulic power pack, for machines not equipped with hydraulics.

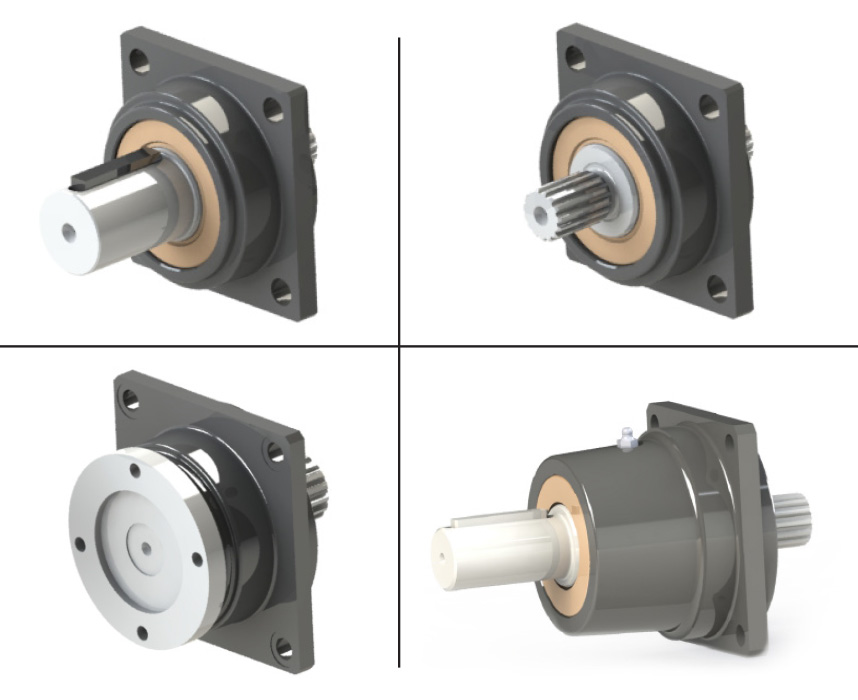

Mounting:

Logan clutches utilize SAE and DIN mounted flanges ranging from A-F male/female splines and can also be bored and keyed. Clutches can be directly mounted to the power source via a standard SAE or DIN flange and connected directly to the auxiliary pump using the output flange of the clutch. Standard u-joint / cardan shaft connections can be connected to either or both sides of the Logan PTO clutch utilizing a Logan companion flange and overhung load adapter. Custom overhung load adapters (OHLA) are available for specific design requirements.

Manifolds:

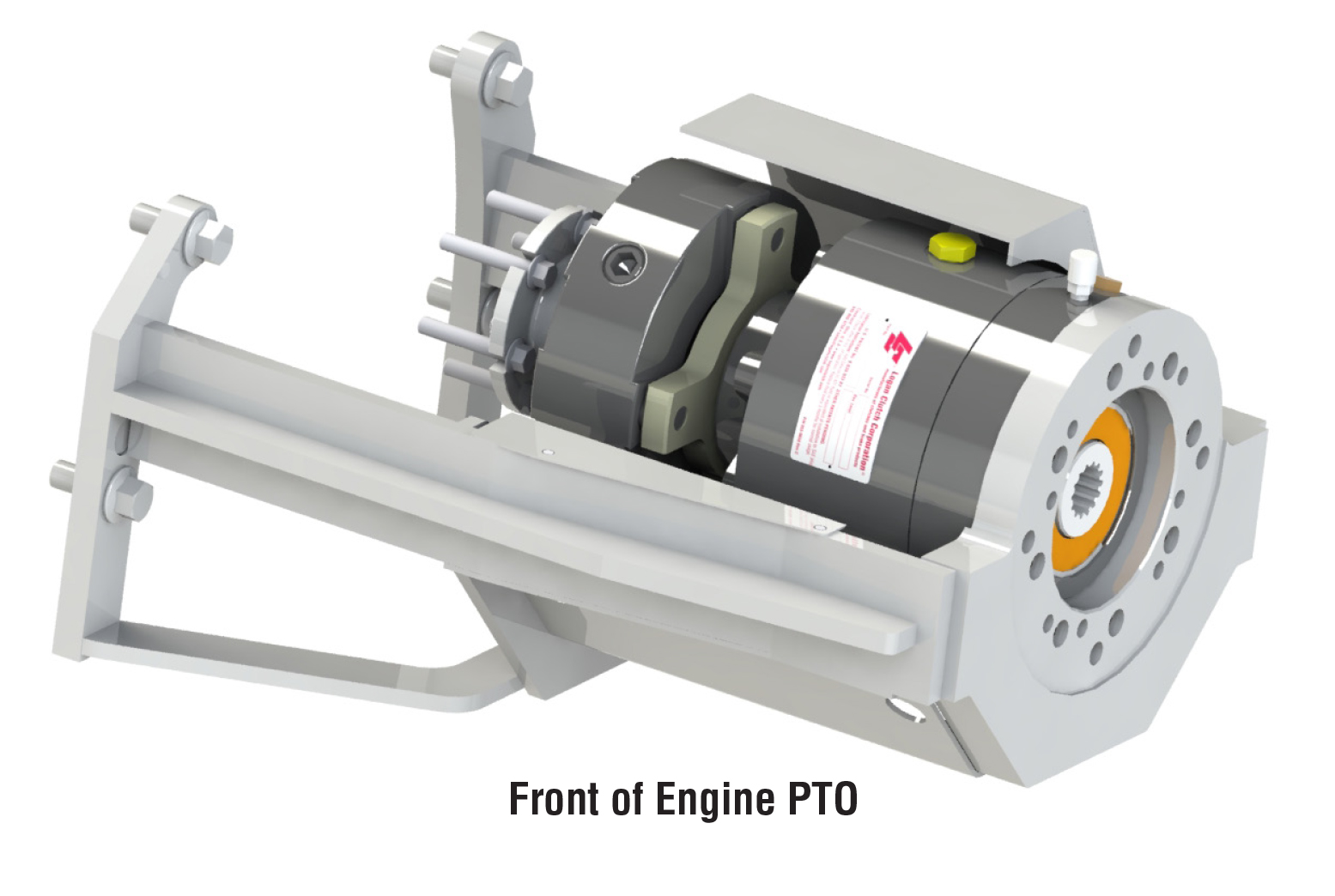

Front-of-engine mounting is possible using a Logan Universal front-of-engine PTO kit or a custom front-mount bracket designed for the specific engine makes and models.

Where used:

Logan Clutch PTO used as a connect-disconnect for a mobile auxiliary drive Logan PTO clutches are typically used as a connect-disconnect for power take-off driven pumps and are suitable for marine, mobile, and stationary equipment, as well as construction, forestry, railroad, utility, mining, and agricultural applications. Other applications include marine transmissions, generator sets, winches, multiple pump drives, fire trucks, and diesel engines with flange-mounted hydraulic pumps.

Logan Clutch PTO used as a connect-disconnect for a mobile auxiliary drive Logan PTO clutches are typically used as a connect-disconnect for power take-off driven pumps and are suitable for marine, mobile, and stationary equipment, as well as construction, forestry, railroad, utility, mining, and agricultural applications. Other applications include marine transmissions, generator sets, winches, multiple pump drives, fire trucks, and diesel engines with flange-mounted hydraulic pumps.Logan Advantages:

Logan PTO clutches enable you to engage and disengage your main or auxiliary driveline on demand, providing you with several operational, environmental, and maintenance benefits.

Operational benefits:

Ideal for cold start and heavy-duty operating conditions: By disconnecting the hydraulic system from the engine, the Logan PTO lowers horsepower draw and increases cranking power required during engine start-ups, or cold starts. Clutches can also disconnect parasitic pump loads to provide full engine horsepower during heavy-duty operating conditions. Easing the load on your engine prolongs engine life and can extend service intervals.

Cooler Running Hydraulic Systems:

Excessive heat is a leading mode of failure in hydraulic systems. Seal compounds and oil viscosity will begin to break down at a faster rate, causing leaks and buildups in the system that will reduce operating life. Disconnecting the hydraulic system from the engine using a Logan PTO clutch, cools the system down and reduces the destructive effects of heat on your hydraulic oil – lowering fluid power maintenance costs and oil replacement.

Double Your Pump Life:

When piston or vane pumps are running in bypass mode, the fluid continues to build heat. This heat can cause the packing to melt, and in the case of water pumps, crack or shatter the plungers. The cost of adding a clutch to your system is a fraction of the cost to shut down your system and replace a worn pump. Engaging your pump on-demand vs. leaving it running all the time could double your pump life. Reduce Maintenance Costs - Since pumps are driven on demand, and no longer in continuous use, bushings, bearings, lip seals, and ring seals in your pump will last longer.

Disconnect Hydraulics for Trouble Shooting:

Another key benefit of using a Logan clutch in your fluid power system is the ability to disconnect your hydraulic system from the engine without having to shut the engine down to troubleshoot any leaks or system failures.

Overspeed Protection for Pumps and Motors:

Clutches offer over-speed protection for hydraulic pumps and motors in mobile applications. By disconnecting hydraulic components from the main power source, all moving parts in the pumps and motors are protected from excessive rotation and movement during machine transport.

Logan Clutches Provide Lower Fuel Costs and Emissions:

Even if a hydraulic system is 100% efficient, it still uses fuel to power the unit. Most hydraulic pumps perform an application-specific task and may run only 25-50% of the time. By engaging and disengaging your pump with a Logan PTO clutch on-demand, fuel savings, and emissions are directly proportional to the fewer operational hours placed on the pumps.

Lower Fuel Consumption:

Typical marine or industrial engines that utilize Logan PTO clutches are in the range of 350-600 kW/HP. A typical unloaded hydraulic pump may draw 5% of the total power – therefore, fuel savings would be around 5% if the pump is de-clutched. Engine Speed, pump load, and operating profile are also factors to consider. For example, a 5% savings may save 1 gallon per 8-hr. day or 365 gallons per shift year.

Lower Emissions:

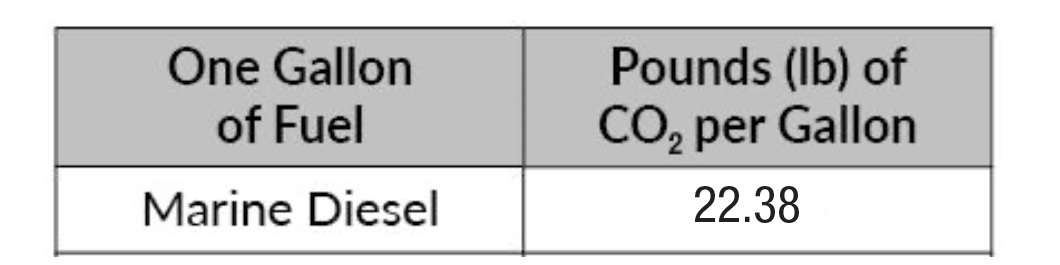

Disconnecting your pump with a Logan PTO can save approximately 365 gallons of fuel per shift year (based on 1-gallon per 8-hr. shift savings), and approximately 8,168 lbs. of CO2.

Calculate Your Savings:

Formula: 10,180 grams of CO2/gallon of diesel = 10.180 × 10-3 metric tons CO2/gallon of diesel Data sources: Department of Energy (DOE) Alternative Fuels Data Center (AFDC) Properties of fuels.