Logan SPF 1000 Series Front of Engine Power Take-off (PTO) clutches supply on-demand connect/disconnect power to the hydraulic systems that run the deck winches and sailing equipment on the sailing yacht Hetairos

The Challenge

The sailing yacht Hetairos is a 67m / 220ft carbon ketch built by Baltic Yachts and Dykstra & Partners naval architects. Originally launched in 2011, the vessel was overhauled in 2015. Built with a desire for both long distance cruising and competitive sailing, the design needed to balance power and weight. When Hetairos was completed in 2011, it was powered by 4 Volkswagen Engines, each contributing in some way to the hydraulics for propulsion via thrusters, hydraulics for deck and sailing equipment, and electrical generation. The control system for this arrangement was unable to reliably provide consistent power, leading to a number of blackouts and breakdowns.

The Solution

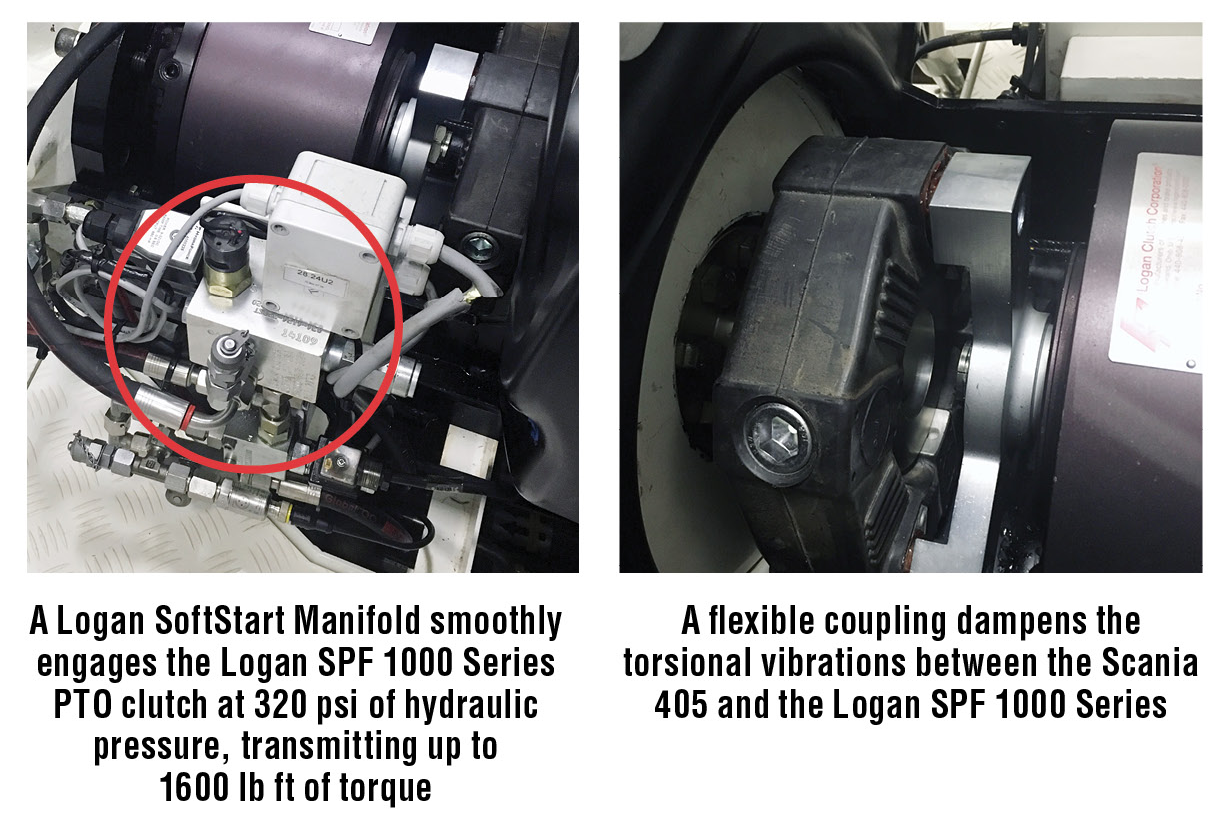

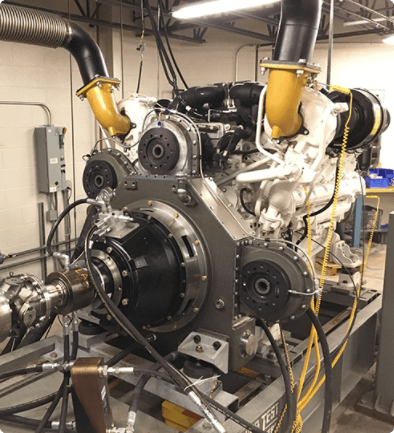

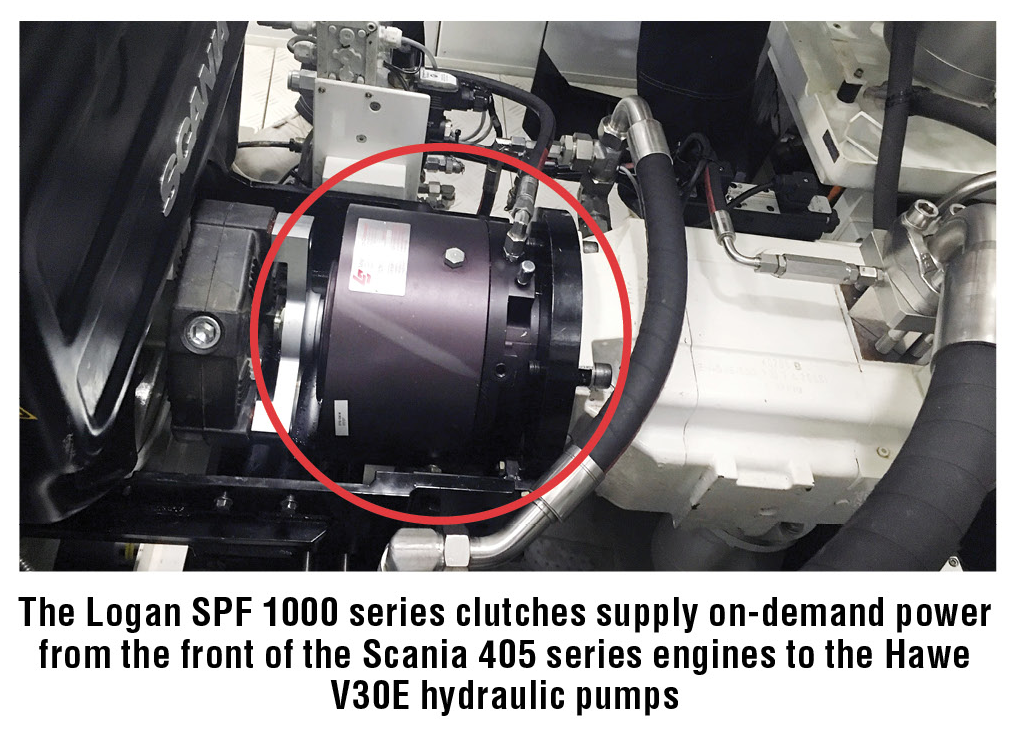

In 2015, Hetairos was refitted with 2 dedicated electric generators--one 75 kW exclusively for electricity and another 90 kW for electricity and some hydraulics. In addition, twin Scania 405 engines are now used to directly drive the thrusters. Most of the vessel’s hydraulics are powered off the front of the Scania 405’s with Hawe Hydraulik V30E pumps supplied with on-demand power via Logan SPF 1000 Series PTO clutches. The Logan SPF 1000 Series clutches are mounted to the front of the Scania 405 engines via Logan Front Mount Kits. A Logan Manifold with SOFTSTART™ engagement provides 320 psi of hydraulic pressure to smoothly actuate the clutch at up to 1800 rpm. Operating speeds can reach up to 3000 rpm.

Now, during racing, since the retractable thrusters are not in use, the Scania 405 engines are used exclusively for the hydraulics that power the deck and sailing equipment. The engines sit in idle and rev up and down based on the load—the Logan PTO clutches give the crew instant power when they need it. Overall, this new hydraulic system easily meets the maximum oil flow requirements of 231 gallons/min (875 L/min) during gybing and tacking maneuvers. The system yields line speeds on winches of 6.5 ft/s (2 m/s) and allows the crew to hoist the spinnaker in under 50 seconds.

Exceeds Expectations

For Captain Graham Newton, the adjustment to the hydraulic systems is key to being able to fulfill the appropriate demands for racing the yacht, “particularly because you can control the speed of each winch,” he elaborates. “The functionality is incredible – in Porto Cervo the trimmer on the primary winch was actually telling us to slow down because they couldn’t tail fast enough.” Also, by engaging the hydraulic system on-demand, the Logan PTO clutch provides significant savings in fuel consumption, component longevity, and lowers C02, NOx, and SOx into the environment.

.png)