The Challenge

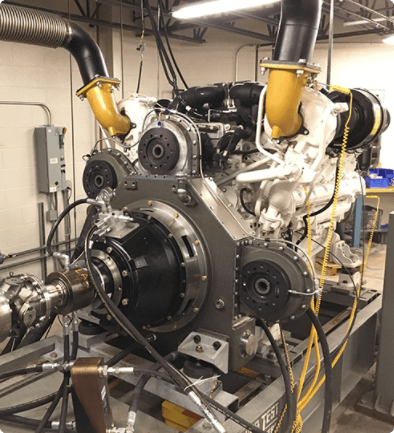

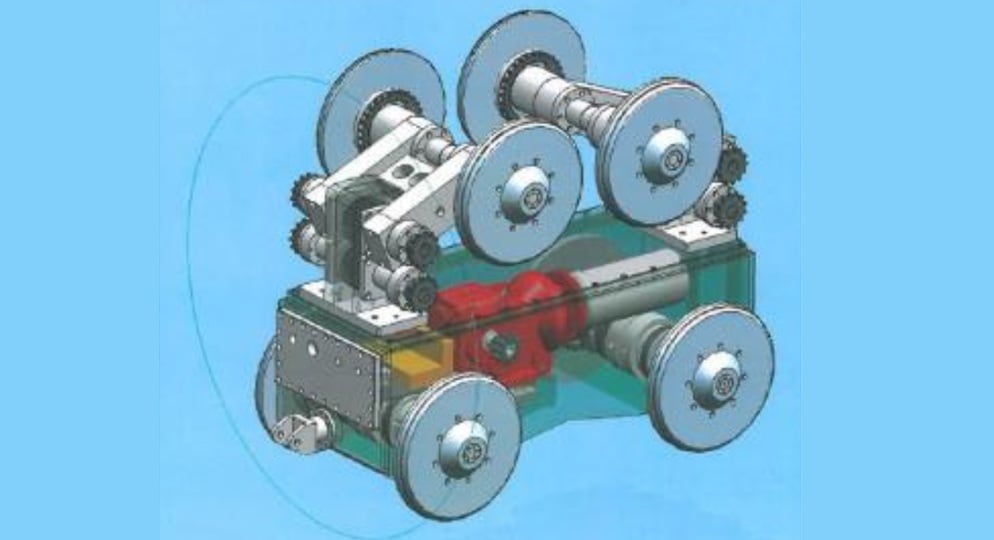

To develop a unit that can go through an oil pipeline that is capable of doing measurements and still be strong enough to carry a cable through the pipe-line. Besides the pipeline being limited in space there are sometimes small obstructions to past through larger welds and dirt in spots. The customer solution was to build a Robot to do this work. Inside the robot there would be an electrical motor connected to a gearbox. That gearbox is connected to 2 axles. On each axle there are 2 clutches (4 clutches in total) and when there is an obstruction in the line there can be a peak load on one of the axles. A second later the other axle will help and the torque will be divided on each axle The peak load is only for a short moment, usually less than 5 seconds to pass the obstruction. If longer the electrical power drops in half to a safety mode. This means the torque to the clutch or the unit will never be above specifications. The start and stop of the unit is always without load so a clutch that does not slip is required.

The Journey

The Journey

A clutch needed to be supplied that was small enough to fit in the required envelope and still meet the torque requirements of the customer. A Logan PTO direct drive clutch would be a first choice but due to space limitations there was not a standard unit small enough to fit that would have the required torque. Logan then moved to a P-style clutch. The clutch is self-contained but not enclosed with a separate drive cup. Working with the customer’s envelope Logan was able to add a disc to the standard unit to meet the customer’s size and torque requirements. The clutches were enclosed in the customer’s units and a prototype was supplied. The customer prototyped the units and all the necessary testing was performed. No issues were discovered.

The Solution

The developer and the end user were completely satisfied with the performance of the Robot. They again tested the clutch inside the robot for several months. The end result was that Logan received multiple unit orders for the clutches and was able to meet the delivery requirements.