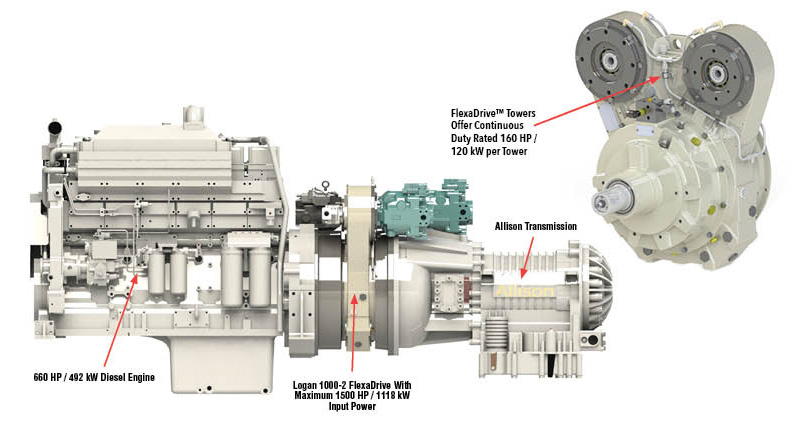

Logan FlexaDrive Series Description:

The Logan FlexaDrive multiple pump drive system is a self-contained gearbox with integral flexible coupling, providing full engine power between your engine (power take-off) and transmission. Three (3) different models, offering from one (1) to five (5) pump towers, offer up to ten (10) PTO/PTI pump pads with bi-directional rotation for engines ranging from 200 HP (150 kW) to 5000 HP (3700kW) at a maximum 2600 RPM (modified standards available). Various step-up ratios are available for direct drive PTO’s, with standard ratios offered from 1:1 to 1:1.25.

Oil Field Applications:

FlexaDrives are ideal for use in applications where they can be mounted between a diesel engine and Allison and Cat CX style transmission – transmitting full engine power through to the transmission, while offering up to 160 HP (120 kW) per tower for hydraulic pumps and equipment.

2-position Pump Drive System For Engines Up to 1000 HP (745 kw)

The Logan 2-Position Pump Drive is outfitted with up to four (4) PTI / PTO pads, and can accommodate up to 1000 HP (745 kW) Engines, with maximum Speeds up to 2600 RPM, and a maximum of 160 HP (120 kW) per tower under continuous duty. Modified HP options available.

- Input Housing SAE No. 1 – No. 3

- Output Housing SAE No. 1 - No. 3

- Pump Pads SAE A – SAE D

- Continuously Rated – Total 300 Hp (225 kW)

- Continuously Rated – Per Tower 160 Hp (120 kW)

- Integrated Reservoir - Eliminates need for secondary tank

- Pump Drive Towers can be positioned up to 45º in either direction

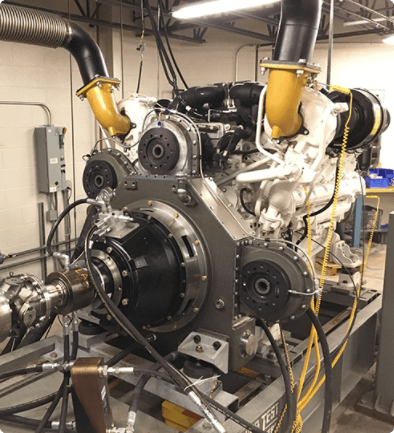

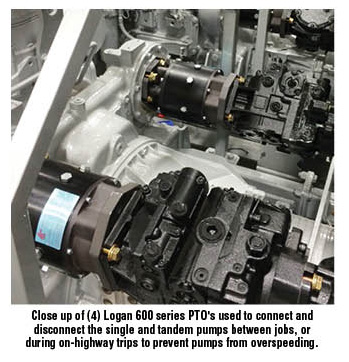

In this Oil & Gas vehicle application, the Logan SAE 600 series Direct Drive PTO is mounted on a typical 2-pad live PTO pump pad, sandwiched between a CAT 3412 Diesel Engine and an Allison 8900 Series Transmission. The Logan 600 series Direct Drive Power Take-off (PTO) clutch will connect or disconnect the single and tandem pumps mounted to the live PTO pump pad. The pumps are used only on the job site, and remain disconnected (via the Logan PTO) when the vehicle is idle and not in use, or when driving to and from the job site. This option to clutch-in and clutch out the pumps minimizes wear and tear on the pumps, reduces unnecessary fuel consumption, and the chances of over speeding the pumps (since they are disconnected from the drivetrain) when the vehicle is at highway speeds during transport.

In this Oil & Gas vehicle application, the Logan SAE 600 series Direct Drive PTO is mounted on a typical 2-pad live PTO pump pad, sandwiched between a CAT 3412 Diesel Engine and an Allison 8900 Series Transmission. The Logan 600 series Direct Drive Power Take-off (PTO) clutch will connect or disconnect the single and tandem pumps mounted to the live PTO pump pad. The pumps are used only on the job site, and remain disconnected (via the Logan PTO) when the vehicle is idle and not in use, or when driving to and from the job site. This option to clutch-in and clutch out the pumps minimizes wear and tear on the pumps, reduces unnecessary fuel consumption, and the chances of over speeding the pumps (since they are disconnected from the drivetrain) when the vehicle is at highway speeds during transport.

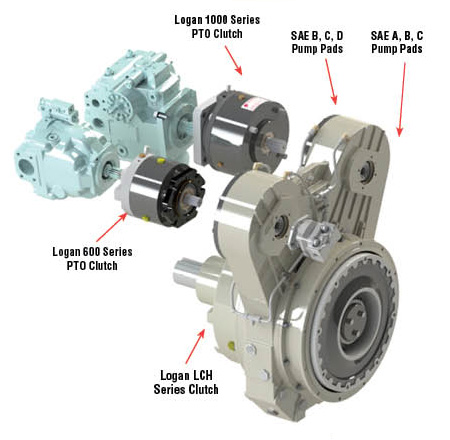

Logan Direct Drive Power Take-off (PTO) Clutches

How They Work:

Direct Drive PTO’s are self-contained, fluid or

air activated clutches, positioned between

a live PTO pad and hydraulic pump.

PTO Clutch Advantages:

- Reduces fuel consumption and CO2 emissions by engaging drives and

pumps only when required - Better Engine Starts: Reduces horsepower draw and cranking power required during machine start-up by disconnecting the hydraulic system from the engine

- Reduced ambient noise through intermittent use of pumps and equipment

- Cooler running hydraulic systems: Heat is generated whenever oil dumps from high to low pressure without producing work.

- Disconnecting the PTO Clutch reduces the destructive effects of heat – lowering maintenance costs and hydraulic oil service requirements

- Extends the life of drive systems and components

- Standard PTO clutches available in A, B, B-B, C, C-C, D and other popular sizes