“Over the 5 years we’ve been working with Logan, our technical support calls for clutches have been cut by 75%”

– Curtis Crocker, Technical Support Lead at Hog

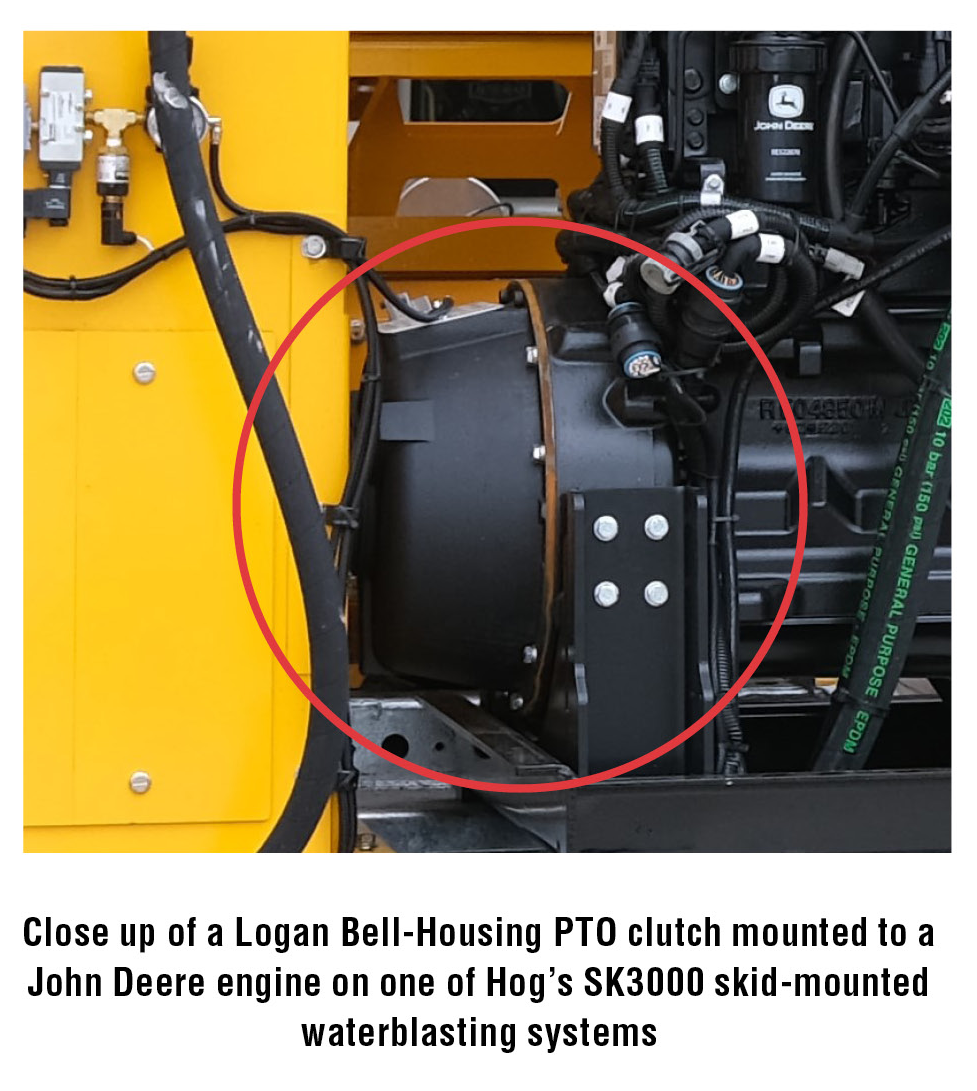

With vehicles operating in over 80 countries, Hog Technologies of Stuart, Florida has a variety of waterblasting products that are powered either via a PTO off the main vehicle engine or via a dedicated auxiliary engine. Hog switched from Twin DiscTM mechanical clutches to Logan Self-Adjusting Bell-Housing Power Take-off clutches for most of their auxiliary engine powered waterblasters. On the auxiliary engine driven products, Logan Bell-Housing PTO clutches provide connect-disconnect power from the engines to engage the waterblasting pumps. These waterblasters are used in a variety of applications, including pavement marking removal, roadway cleaning, airport runway rubber removal, and more.

The Challenge:

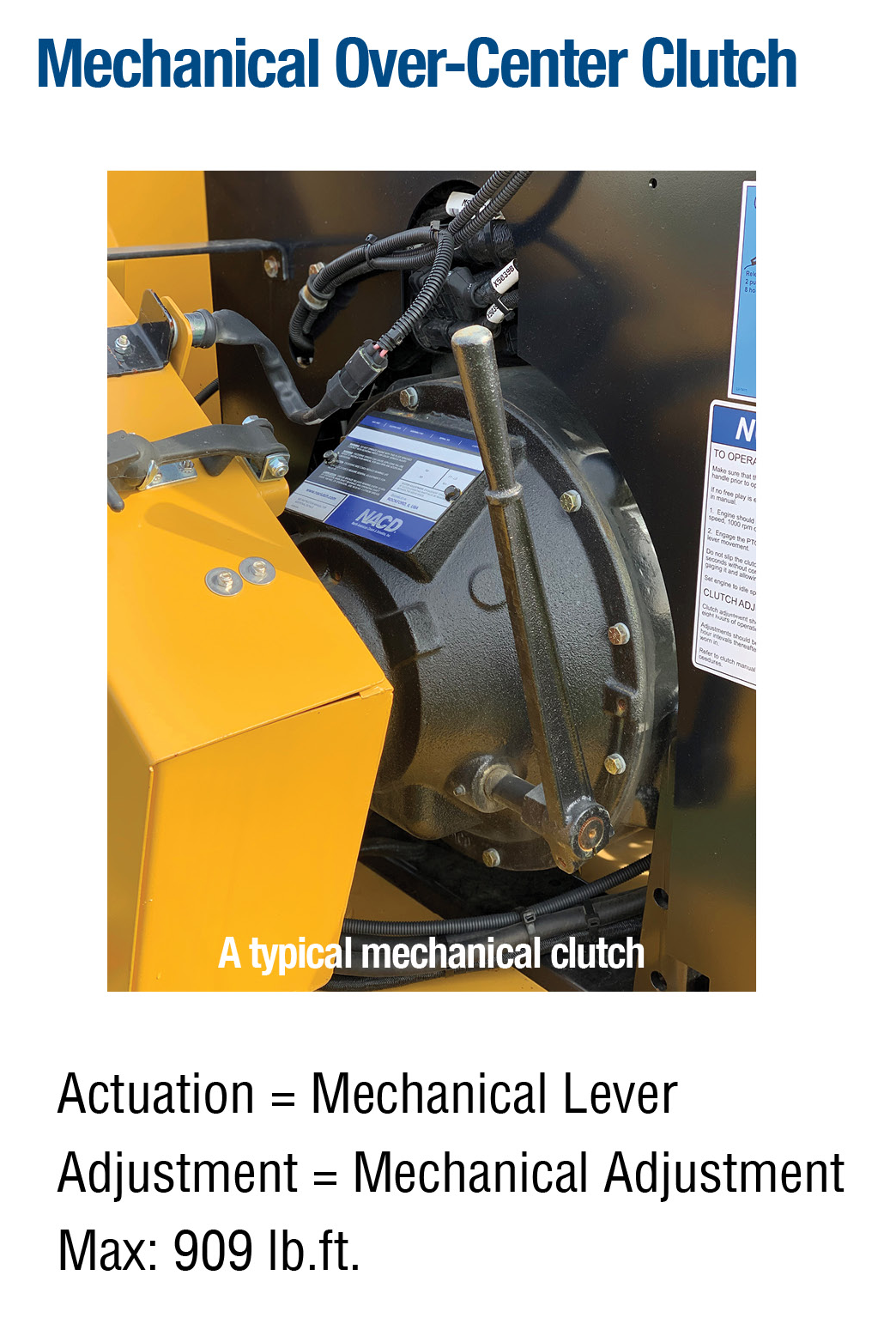

Hog Technologies has customers all over the world. In order to help their customers make the most of their equipment, Hog will perform 4 days of on-site training. With the mechanical clutches, this training included operation of the lever arm for clutch engagement, manual adjustment of the clutch plates, and other clutch maintenance requirements. “The issue with the mechanical clutches is that the torque needs to be checked on a regular basis and reset; a lot of customers aren’t doing that, and they’re burning their clutches out,” says Curtis Crocker, Technical Support Lead at Hog. Crocker continues, “No matter what we did--we had manuals, we had videos, we had the in-person training--the operators are so busy with other things that it’s hard to keep up with the constant maintenance of mechanical clutches.” This damage would lead to frequent downtime for the operators and countless hours of technical support calls for Crocker and his team.

Hog Technologies has customers all over the world. In order to help their customers make the most of their equipment, Hog will perform 4 days of on-site training. With the mechanical clutches, this training included operation of the lever arm for clutch engagement, manual adjustment of the clutch plates, and other clutch maintenance requirements. “The issue with the mechanical clutches is that the torque needs to be checked on a regular basis and reset; a lot of customers aren’t doing that, and they’re burning their clutches out,” says Curtis Crocker, Technical Support Lead at Hog. Crocker continues, “No matter what we did--we had manuals, we had videos, we had the in-person training--the operators are so busy with other things that it’s hard to keep up with the constant maintenance of mechanical clutches.” This damage would lead to frequent downtime for the operators and countless hours of technical support calls for Crocker and his team.

The Solution:

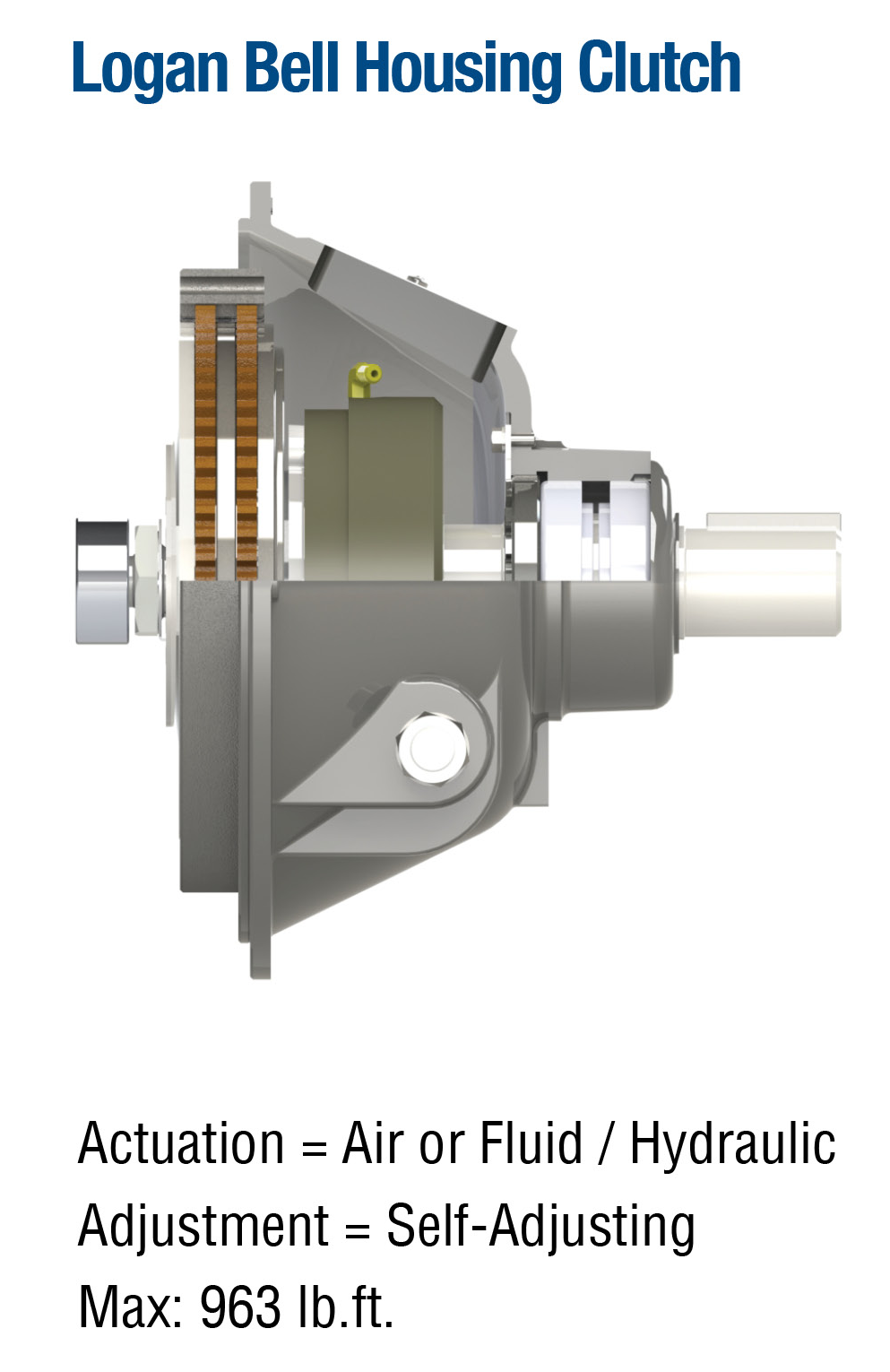

Hog engineers found that the Logan Bell-Housing PTO clutches could replace the mechanical Twin DiscTM clutches. The Logan clutch fits in the same envelope size as the mechanical clutches, allowing for seamless integration. The Logan Bell-Housing PTO clutches are self-adjusting and actuated either pneumatically or hydraulically, thus eliminating the need for manual torque adjustments and manual engagement via the lever arm. The Logan Power Pack allows the Logan clutch to be activated by a simple push-button, and the Logan manifold provides SOFTSTART™ engagement--smoothly engaging the clutch.

Hog engineers found that the Logan Bell-Housing PTO clutches could replace the mechanical Twin DiscTM clutches. The Logan clutch fits in the same envelope size as the mechanical clutches, allowing for seamless integration. The Logan Bell-Housing PTO clutches are self-adjusting and actuated either pneumatically or hydraulically, thus eliminating the need for manual torque adjustments and manual engagement via the lever arm. The Logan Power Pack allows the Logan clutch to be activated by a simple push-button, and the Logan manifold provides SOFTSTART™ engagement--smoothly engaging the clutch.

Results:

“We love the air activated system--you always know how plates are going to be loaded and you don’t have to worry about the maintenance of the torque setting,” says Crocker. Operators appreciate the Logan system as well since it provides reliability for the equipment necessary to run their business. Instead of worrying about their clutch, operators are getting their jobs done. For Hog, the new Logan clutch has streamlined the training process and made Crocker’s technical support work significantly easier: “Over the 5 years we’ve been working with Logan, our technical support calls for clutches have been cut by 75%.”