If you’re looking to increase productivity and reduce maintenance on your Acme-Gridley screw machines, Logan Clutch has the solutions you need. Our Hi-Lo Retrokits™, Air Threading™ Clutches, Pick-off Drives™, and Logan Controls™ are designed to enhance performance and efficiency—allowing you to produce more parts, more consistently, with the same machine, operator, and floor space.

How Logan Clutch Helps You Work Smarter, Not Harder

Many Acme-Gridley machines are still operating with mechanically actuated clutches from the 1940s—a setup that can slow production, require frequent maintenance, and result in inconsistent performance.

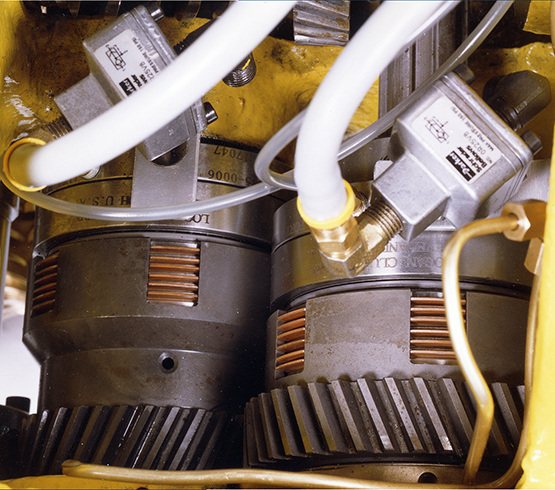

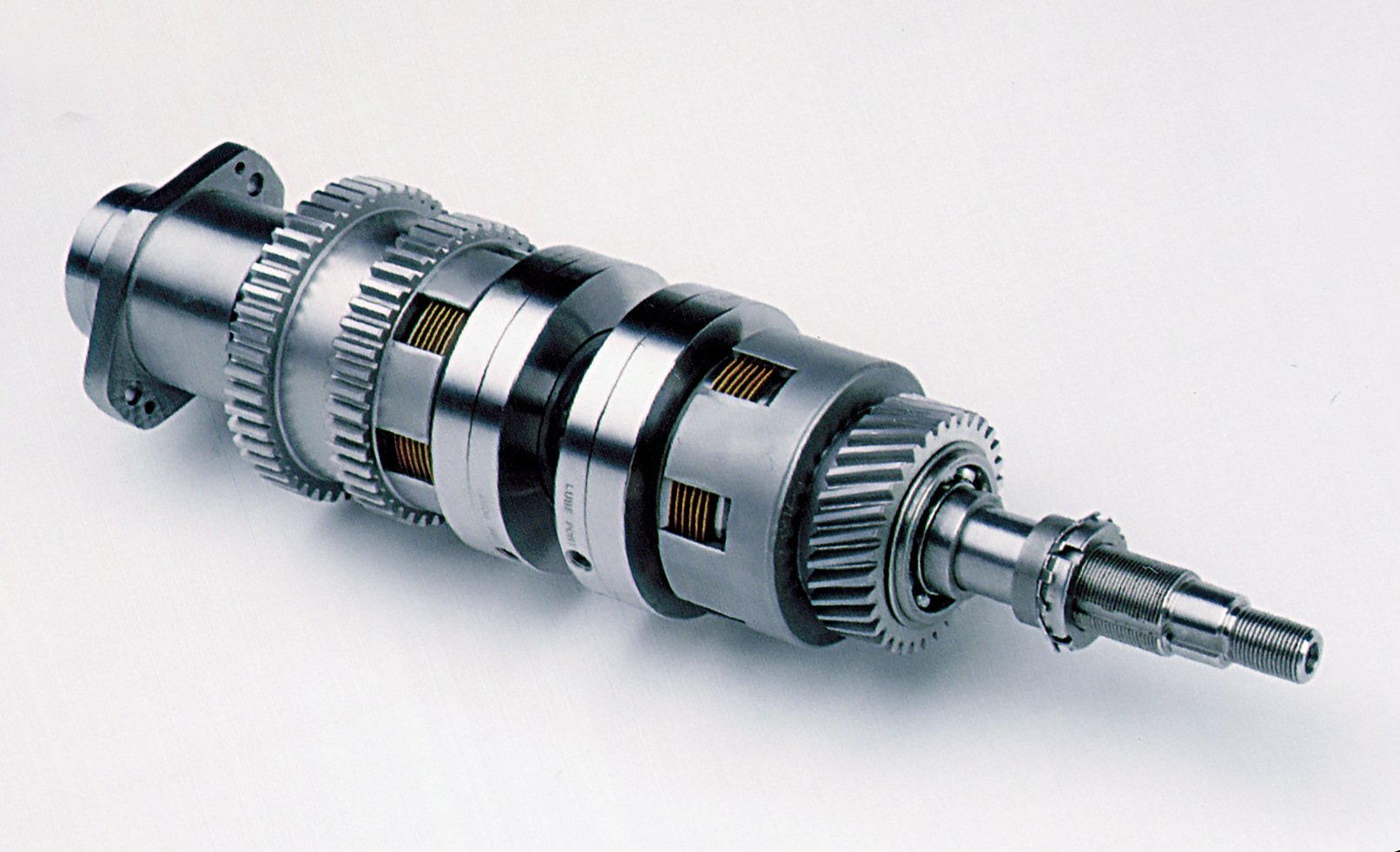

At Logan Clutch, we modernize these machines by replacing outdated components like high-speed and feed clutches, roll clutches, band brakes, linkages, pins, and lever arms with our air-actuated, self-adjusting Logan clutches™.

What Does This Mean for You?

✅ 10-20% or More Daily Output Increases – Logan clutches™ provide faster, smoother speed transitions, reducing downtime and increasing productivity.

✅ Less Maintenance & Fewer Adjustments – Self-adjusting technology eliminates clutch slippage and mechanical adjustments.

✅ Higher Capacity & Profitability – More parts produced per hour, per day, and per week, maximizing ROI on your existing machines.

Logan Air Threading Clutches: Achieve Consistent Tap Depths

One of the most common pain points in threading operations is inconsistent tap depth, which leads to premature tool wear, increased rework, and wasted time.

Our Logan Air Threading Clutches eliminate these issues by providing smooth, positive clutch engagement—ensuring:

- Uniform tap load for better consistency across high-volume production

- Extended tap life and reduced tooling costs

- Fewer tool changes, saving valuable setup and production time

Hi-Lo Retrokits™: Reliable Performance with Minimal Maintenance

Traditional mechanical clutches often result in inconsistent speed changes, requiring frequent operator adjustments. Logan Hi-Lo Retrokits™ solve this by enabling:

- Faster and smoother high-to-low speed transitions

- Accurate and repeatable cycle times

- Reduced downtime and maintenance

Because Logan clutches™ are self-adjusting, you eliminate clutch slippage and mechanical adjustments entirely—giving you consistent performance and increased productivity.

Simplified Machine Setup & Ideal for Automation

For machinists, setup time is critical. Logan clutches™ make it easier to position tools closer to the workpiece while ensuring guaranteed cycle time repeatability.

For automated bar loaders, Logan’s power-applied brake prevents machine coasting, allowing for precise stock-loader positioning. In the event of a fault or start interrupt, the brake immediately stops the machine, ensuring safety and seamless automation.

Maximize Productivity with Logan Controls™

Pairing Logan clutches™ with Logan CS2001G3™ and CS2001XTP™ Controls unlocks even greater efficiency:

- Dialed-in cycle times

- Real-time parts and tool counting

- Thread check functionality

By integrating Logan Controls™, you gain full control over production and minimize human error, leading to a more efficient and profitable operation.