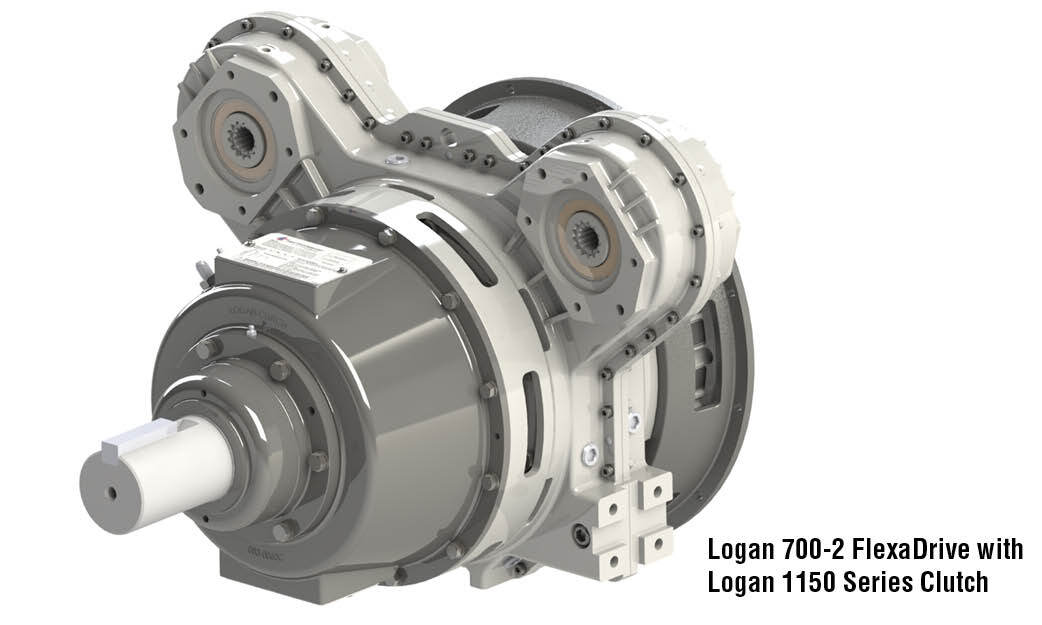

Bell Housing Power Take-Off Clutches™

Bell Housing Series Description:

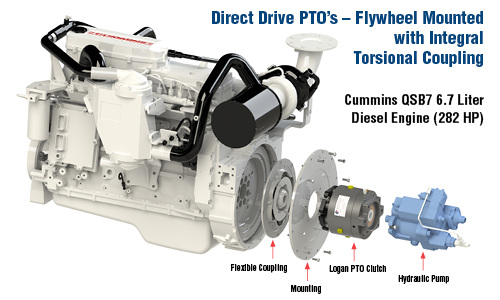

Logan Air / Fluid actuated Bell Housing PTOTM clutches are Self-AdjustingTM and designed to mount directly to a diesel or gasoline engine’s flywheel.

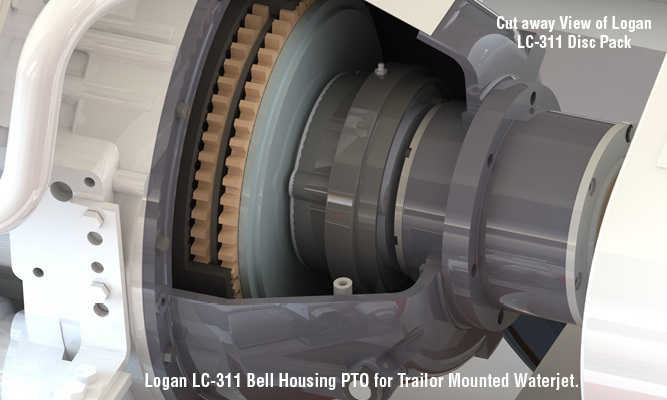

The friction disc packs are designed for dry operation. Actuation is accomplished through either a stationary cylinder-piston arrangement, or through internal shaft and clutch passages.

The clutch is bored and keyseated for shaft mounting. Torque is transferred from the disc pack to a geared drive ring which is attached to the engine’s flywheel.

Logan Clutches – How They Work

Pressurizing the cylinder, forces the piston to clamp and lock the friction and steel separator discs. When pressure is removed, release springs separate the friction and steel discs, maintaining a running clearance when disengaged.

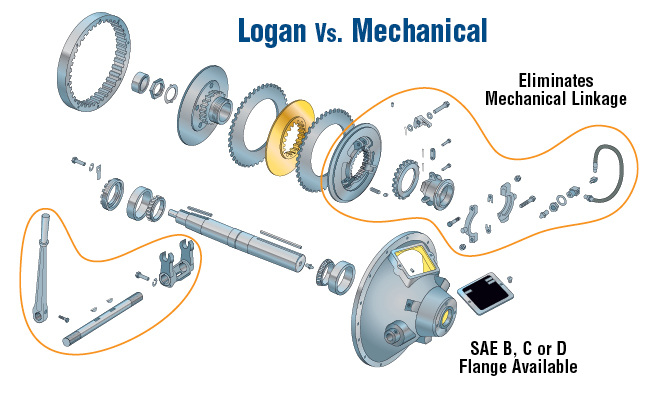

Push Button Actuation - Eliminates Mechanical Linkages.

Self-adjustingTM piston travel compensates for any disc wear, eliminating the need for mechanical adjustment (i.e. levers, linkages, and yokes). The amount of hydraulic or pneumatic pressure applied regulates the amount of torque transmitted through the clutch. Push-button, remote activation from a control panel, marine wheelhouse or cab is now possible.

Standard Specifications:

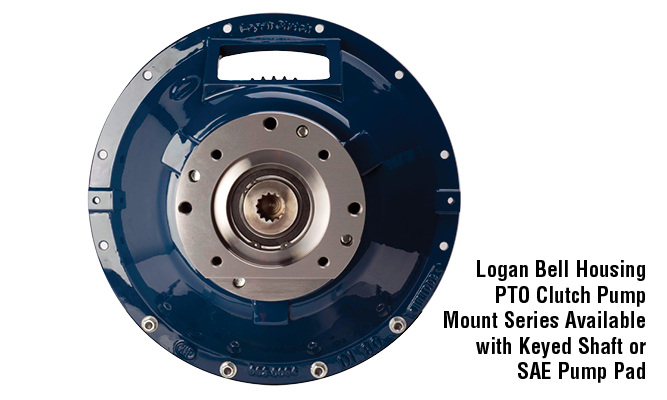

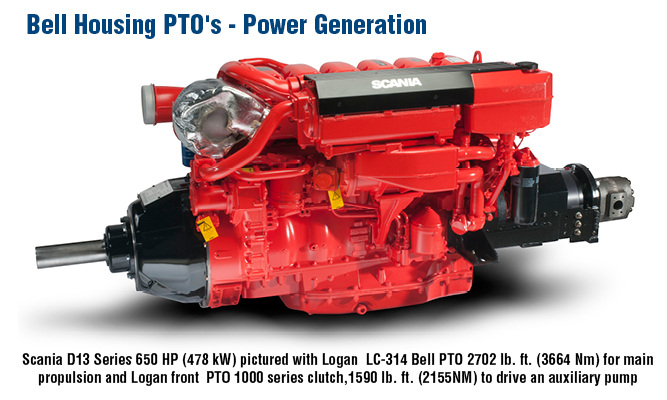

Standard Logan Bell Housing PTO’s are available in No. 00 to No. 7 Size SAE Bells with input torque ratings from 159 lb. ft. (216Nm) to over 7,473 Lb. Ft. (10133 Nm). Logan uses a 1.4 factor of safety in our torque specifications.

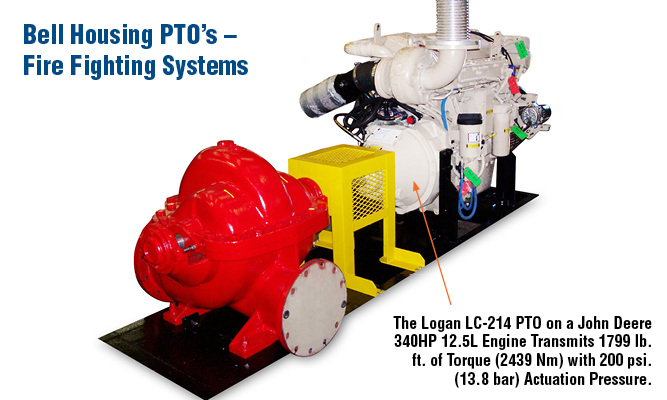

Air / Fluid operating pressures range from 100 (6,9 bar) to 200 psi (13,8 bar) for Generation I and Generation III models; and 320 psi. (23 bar) for Generation II Models.

Operating speeds range from 1 to 3,000 RPM.

Modified Standards:

Higher horsepower, torque ranges, speeds, actuation pressures, and design configurations are available to meet customer’s specific design requirements.

Applications

- Industrial

- Marine

- Agriculture

- Off-Road

- Mobile Equipment

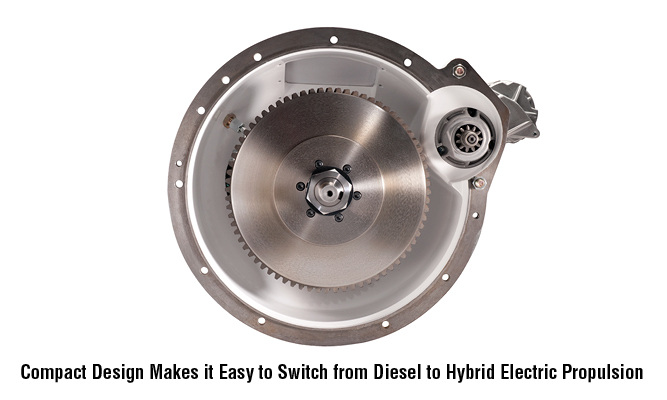

- Hybrid Vehicles

Advantages:

- Air or fluid actuated for remote activation

- Self-adjusting disc pack – flow control engagement

- Eliminates mechanical linkages, hand levers, and yokes

- Available with or without pilot bearing

- Heavy-duty side load models available

- Modified standards available

Bell Housing PTO Products:

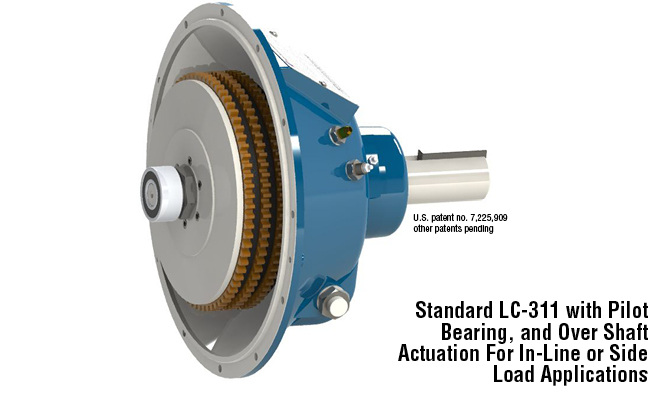

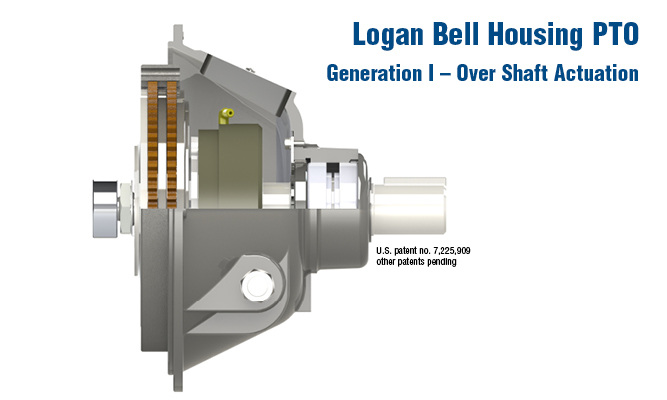

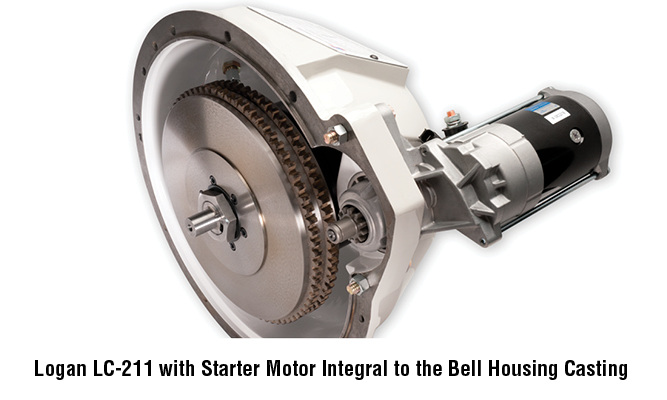

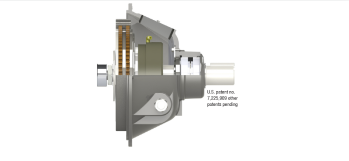

Generation I Over Shaft Actuation with Pilot Bearing

Logan Bell Housing PTO’s are self-adjusting, and over-shaft actuated, using air or hydraulics. Gen I Bell Housing PTO’s utilize a pilot bearing and can retrofit or fit within the same envelope space as most mechanical, over-center PTO clutches. Logan clutch engagement is smooth and positive, eliminating mechanical hand levers, yokes, and sleeves. Since Logan PTO’s are fluid or air actuated, remote engagement from a bridge, wheelhouse or engine control panel is now possible.

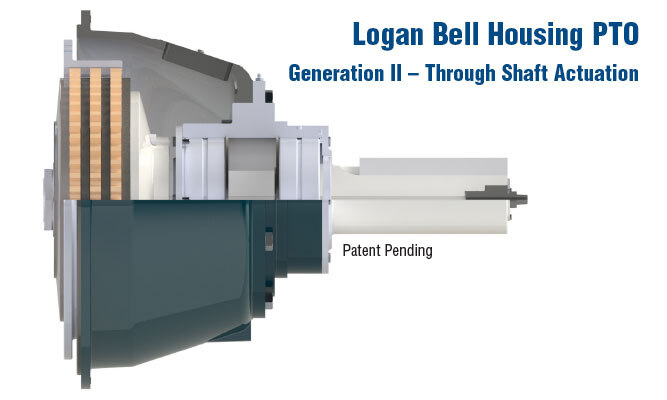

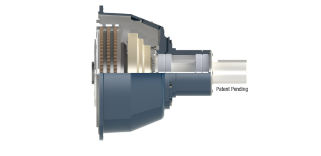

Generation II - Through Shaft Actuation Without Pilot Bearing

Logan Generation II Bell Housing PTO’s do not require a pilot bearing. Clutches are self-adjusting, and through-shaft actuated, using air or hydraulics. Logan clutch engagement is smooth and positive, eliminating mechanical hand levers, yokes, and sleeves. Since Logan PTO’s are fluid or air actuated, remote engagement from a bridge, wheelhouse or engine control panel is now possible.

Marine Applications

Logan PTO’s are suitable for tugboats, workboats, fishing boats, jet boats, patrol boats and pleasure craft. Activation is simplified since Logan PTO’s are fluid or air actuated, enabling remote engagement from the bridge or wheelhouse – and are self-adjusting™, requiring no mechanical adjustment.

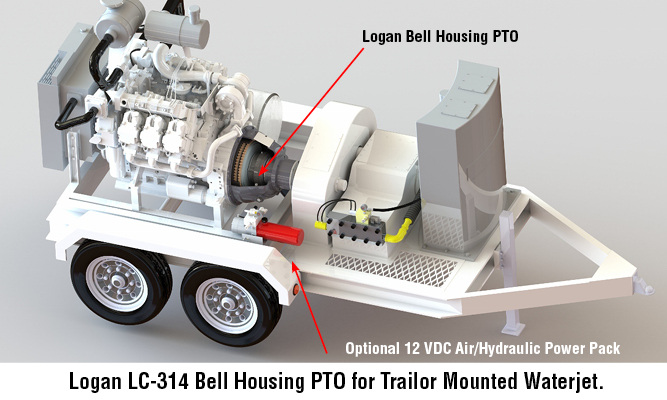

Clutches for Water-Jetting and Water blasting Equipment

Mechanical PTO clutch failures and overhauls can take a water blasting machine out of service for several hours or an entire week resulting in lost revenue and increased operating expenses. Most water blasting units are in rental fleets, which compounds the problem of uptime and downtime from failed mechanical clutches.

Clutches for Pumping Stations

Logan PTO’s are used as a connect-disconnect between diesel engines and water pumps used in pumping stations. Activation is simplified since Logan PTO’s are fluid or air actuated, enabling remote engagement. Since Logan Clutches are self-adjusting™, no mechanical clutch adjustment is required.

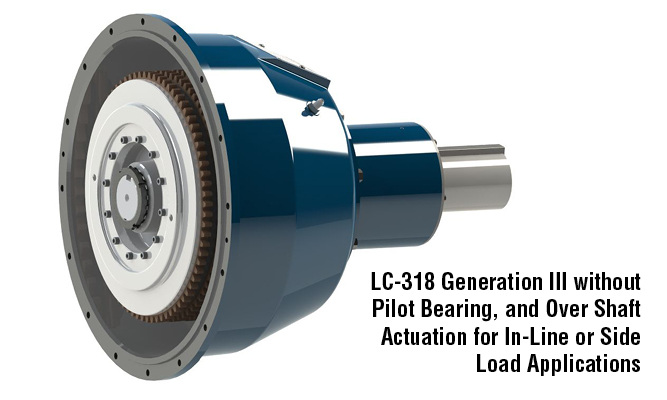

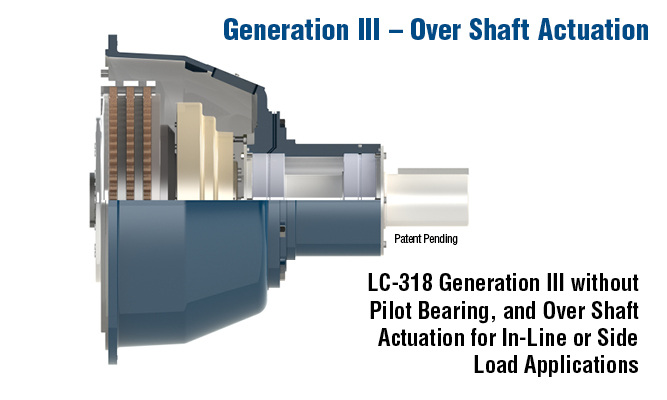

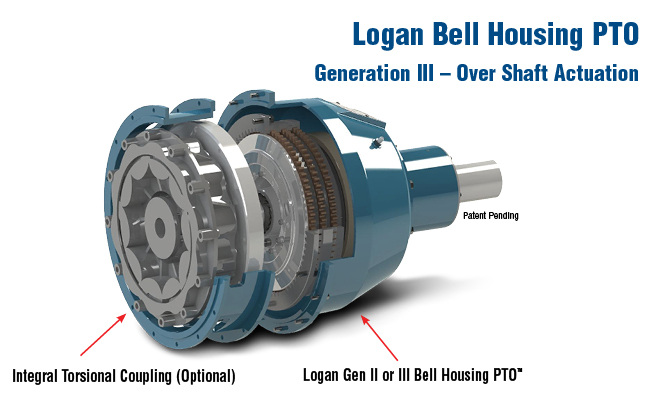

Generation III - Over Shaft Actuation without Pilot Bearing

Logan Generation III Bell Housing PTO’s do not require a pilot bearing. Clutches are self-adjusting, and over-shaft actuated, using air or hydraulics. Logan clutch engagement is smooth and positive, eliminating mechanical hand levers, yokes, and sleeves. Since Logan PTO’s are fluid or air actuated, remote engagement from a bridge, wheelhouse or engine control panel is now possible.

HPU Hydraulic Power Units – Manifolds and Start-up kits

Logan offers Hydraulic Power Units, Manifolds and Start-up kits, which are designed to simplify Logan Clutch installations and to provide reliable engagement of your Logan Clutch.

Tree and Brush Chippers Recycling

Frequent mechanical PTO clutch overhauls can take a chipper out of service for several hours or an entire day, resulting in lost revenue and increased operating expenses. Logan Bell Housing PTO’s are hydraulically actuated, and self-adjusting, eliminating the need for mechanical levers, pins, yokes and other high wear items on your chipper. No Levers!

Snow Blowers

Clearing airport runways is a top priority during winter storms. This heavy-duty snow blower (pictured right), powered by a CAT C-18 Engine, and a Logan LC-314 Bell Housing PTO as part of the blower system – can cast 5,000 tons (4.535e6 Kg.) of snow per hour, over 200 ft. (60.96 meters). That’s approximately 1.4 tons (1,270 kg) per second.

Clutches for Marking Removal Trucks

Logan PTO’s are used as a connect-disconnect between diesel engines and bare shaft and centrifugal pumps. Activation is simplified since Logan PTO’s are fluid or air actuated, enabling remote engagement. Since Logan Clutches are self-adjusting™, no mechanical clutch adjustment is required.