Mounting Options

Mounting Options

Logan SAE PTO Clutches are designed to mount between the power take-off of an engine and an auxiliary attachment, i.e. single or multi-station pump drive.

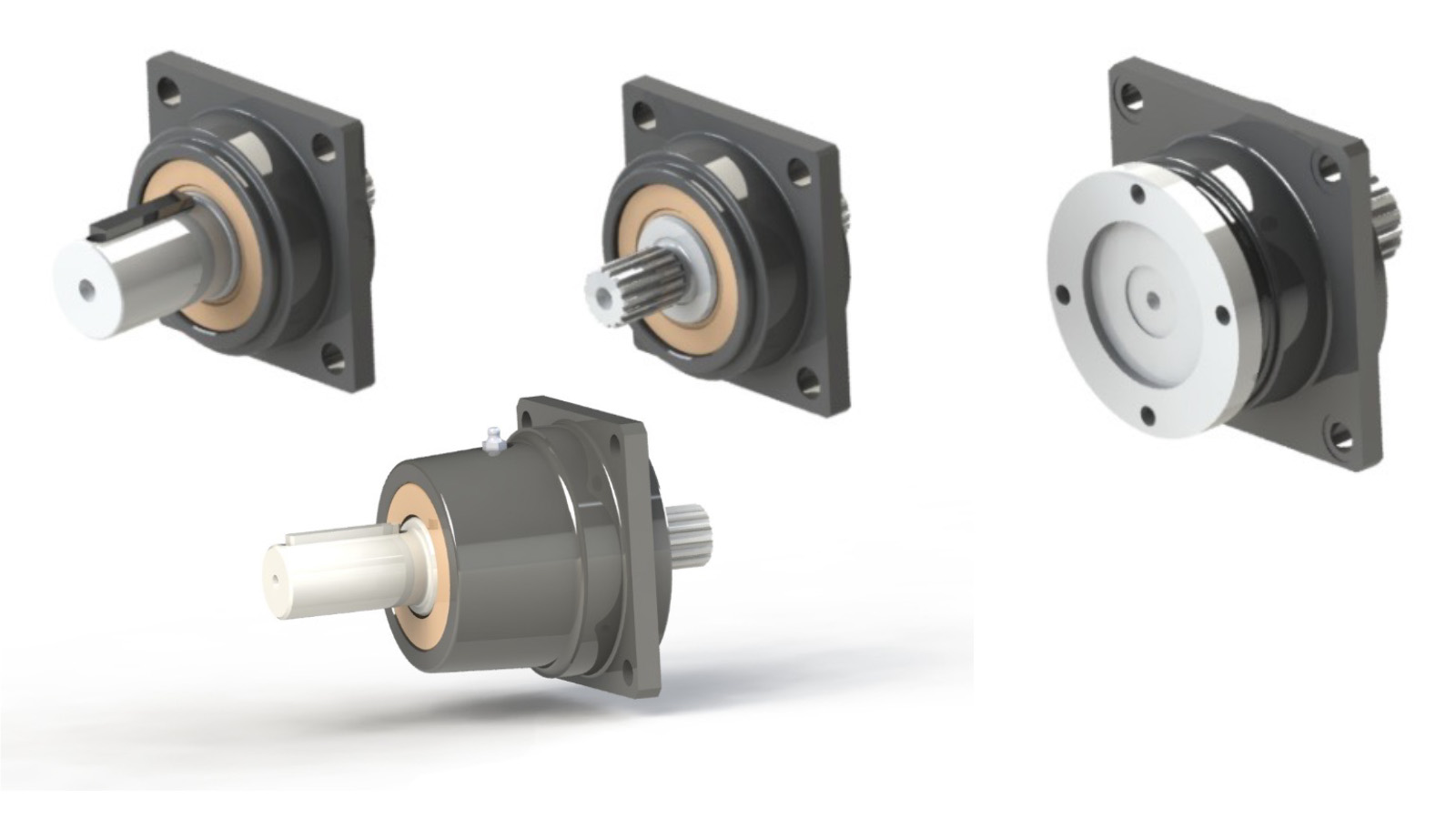

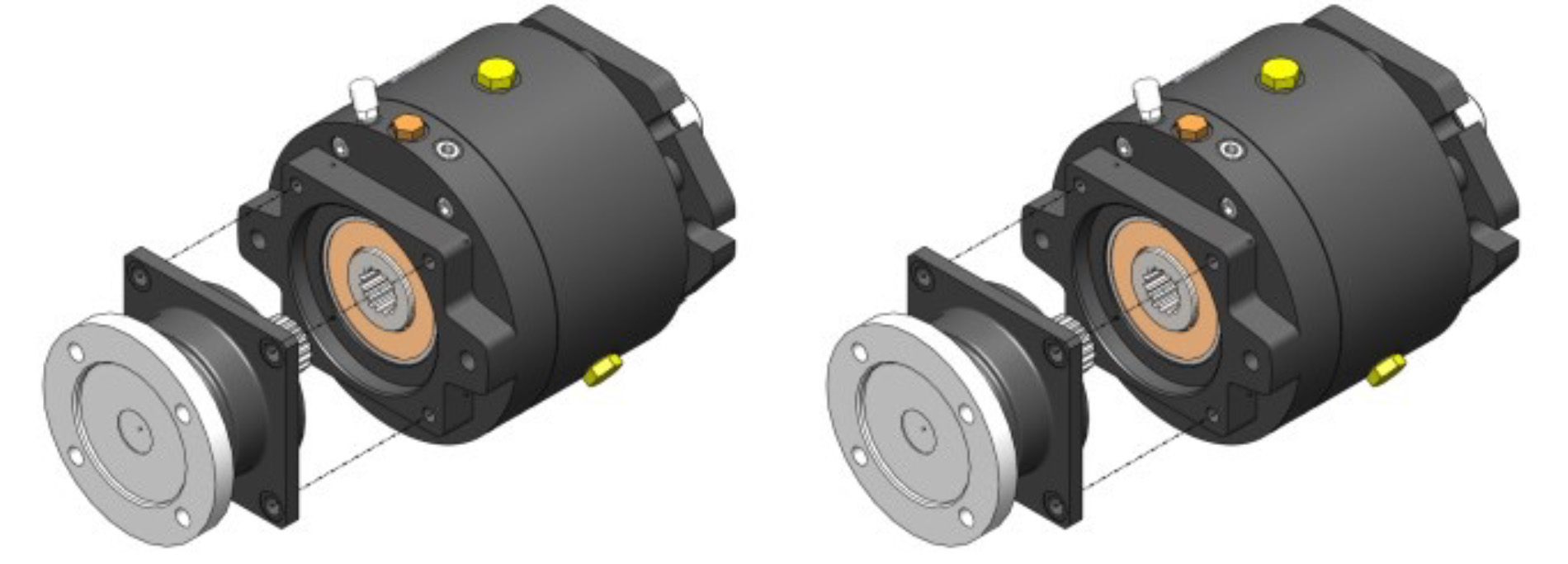

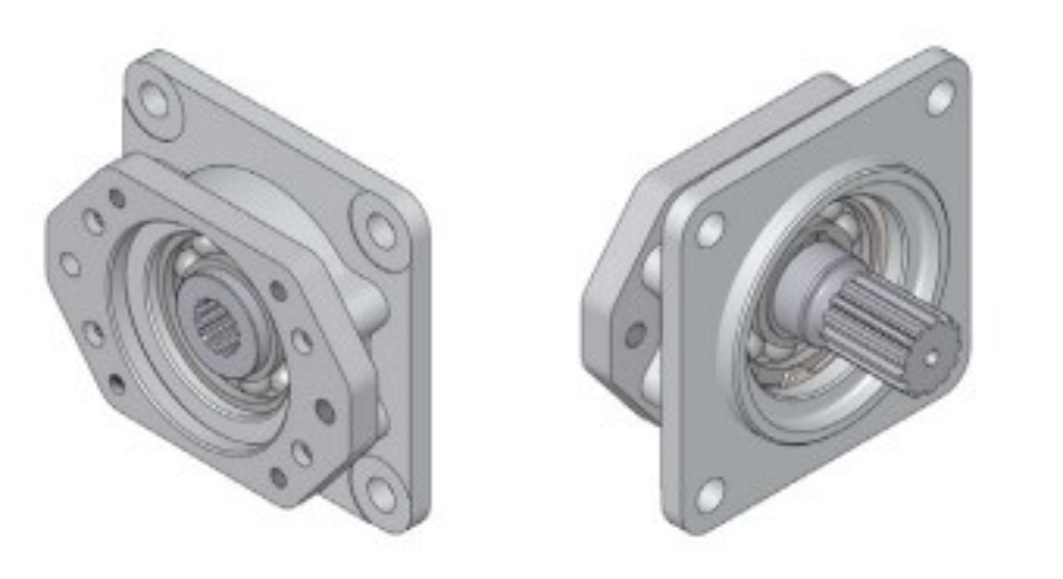

SAE and ISO Flanges: Available in SAE or ISO mounting flanges, with B,C,C-C,D/E and F Splines, plus bore and keyway configurations.

Overhung Load Adapters: (OHLA) Shaft adapters are also available for common Dana or DIN style flanges.

Marine Transmissions: Logan offers SAE 2-bolt and 4-bolt clutches for B Mount facings and SAE 4-bolt clutches for C Mount facings. for low profile, compact applications, such as on the live PTO pad of a Twin Disc style or ZF style transmission,

Logan also offers integral torsional couplings for torsionally active, in line applications.

Flywheel Mounting: Flywheel mounted options which include an SAE flywheel cover plate and torsional coupling.

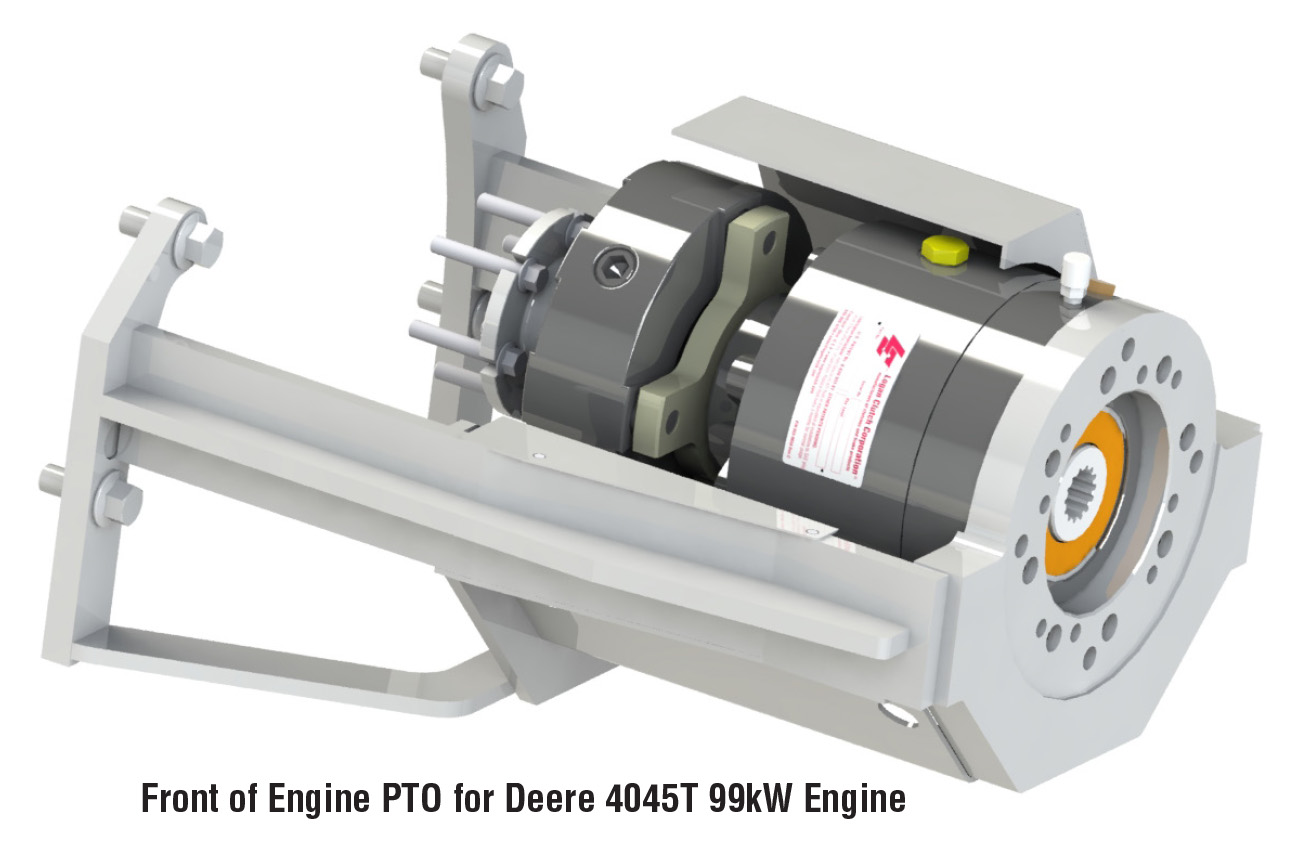

Front of Engine PTO Clutch Brackets: Options for popular diesel engines, gensets, and gensets with sound enclosures.

Universal kit mounting options for legacy engines.

Power Take-off Clutch Mounting Options

Direct Connection to Power Source

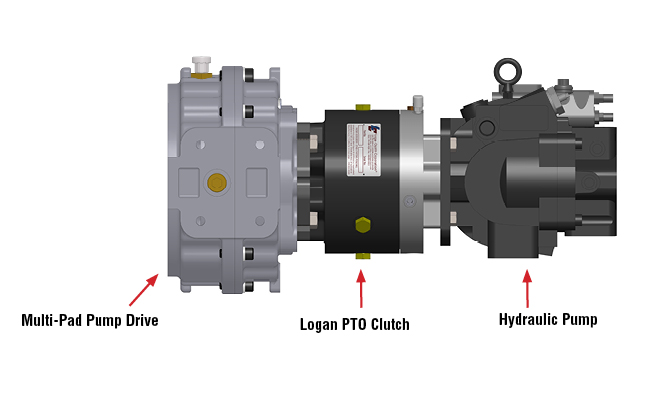

The PTO clutch is directly mounted to the power source via the SAE standard flange. The auxiliary pump mounts directly to the output of clutch, utilizing the same SAE standard flange.

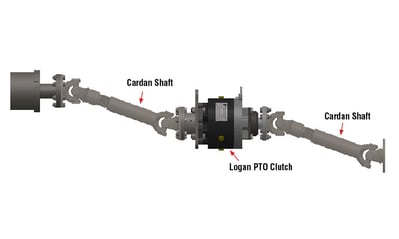

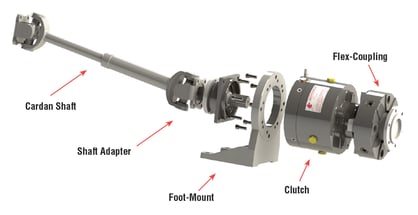

402 Series: Remote Mounting of Auxiliary Pump

Overhung load adapter mounts to the output of the PTO Clutch assembly and allows for moderate side load induced by a cardon shaft.

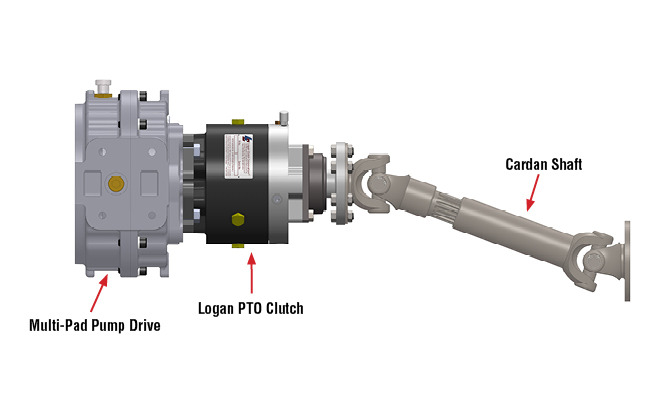

405 Series: Remote Mounting of Consecutive PTO Clutch and Auxiliary Pump

Utilizing the Logan 405 Series companion flange adapters, the remotely mounted PTO clutch input interfaces with a standard Spicer-type flange on a sliding joint cardon shaft.

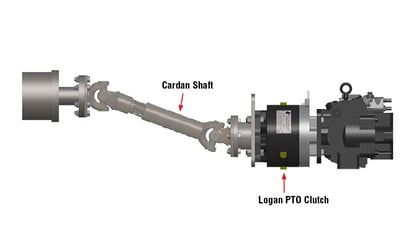

Combination of 405 and 402 Series:

Cardan shafts mounted to both sides of the PTO clutch utilizing a 405 Companion Flange on the input and 402 Overhung Load Adapter on the output.

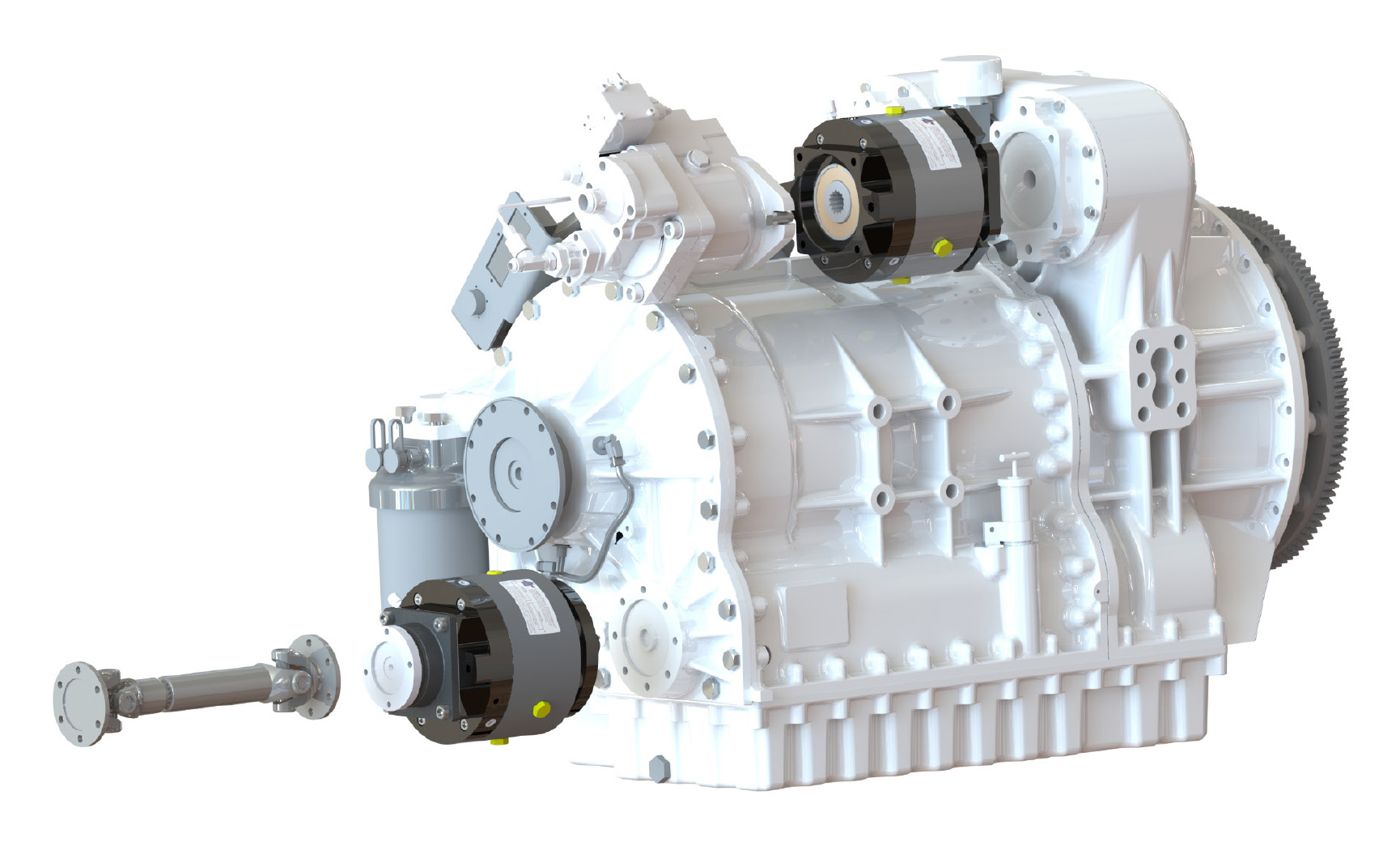

Transmission Mounted:

Direct mount to a Muncie style or Chelsea style PTO mount for Allison type transmissions

Transmission Mounted:

Logan PTO clutches can be directly mounted to a CAT style transmission PTO pad, or rear mounted PTO (REPTO) pad.

Logan PTO clutches can be directly mounted to a CAT style transmission PTO pad, or rear mounted PTO (REPTO) pad.

Logan Direct Drive PTO Clutch kits for engine flywheel mounting

Features:

- Pneumatic or Hydraulic Actuation

- Self-adjusting for wear

- Integral torsional coupling helps eliminate wear from torsional vibration

- The low profile, compact design is shorter than many existing designs

- Available for most popular SAE hydraulic pumps

- Available for most popular Flywheel and Bell Housing sizes

Advantages:

- Standard off the shelf components ensure fast delivery

- Consistent reliable torque transmission

- Easy to select correct size clutch based on pump requirements. No wasted time for specification process

- First nearly every engine manufacturers engine

- Greatly simplifies remote actuation setup

Pump Drive Mounted:

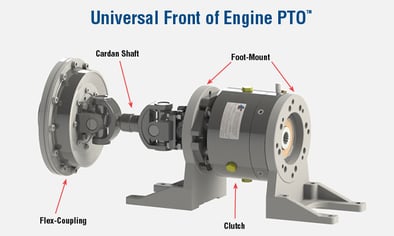

Universal Front of Engine PTOTM

Logan Universal Front of Engine PTO’s incorporate an integral flexible coupling, clutch cardan shaft and bracket arrangement, and are specified when an engineered bracket design is not practical or required for the application. Works with most new and legacy engines and can be installed with fewer alignment procedures.

- Resiliant or rigid mounted engines

- Simple installation procedure

- For installations that require maximum torsional vibration protection

- Used in applications that run with clutch engaged or disengaged

- For use with applications with moderate to high operational misalignment

Cardan Shaft Solution for Low Torsion Applications

For front of engine PTO applications where the output desired is a drive shaft. Engines must be rigidly mounted, properly aligned, display relatively low torsional vibration, and are engaged a majority of the time.

- Economical solution

- Rigidly mounted engines only

- Used with engines with low torsional vibration

- Used in applications that run with clutch principally engaged

- For use with applications with low operational misalignment

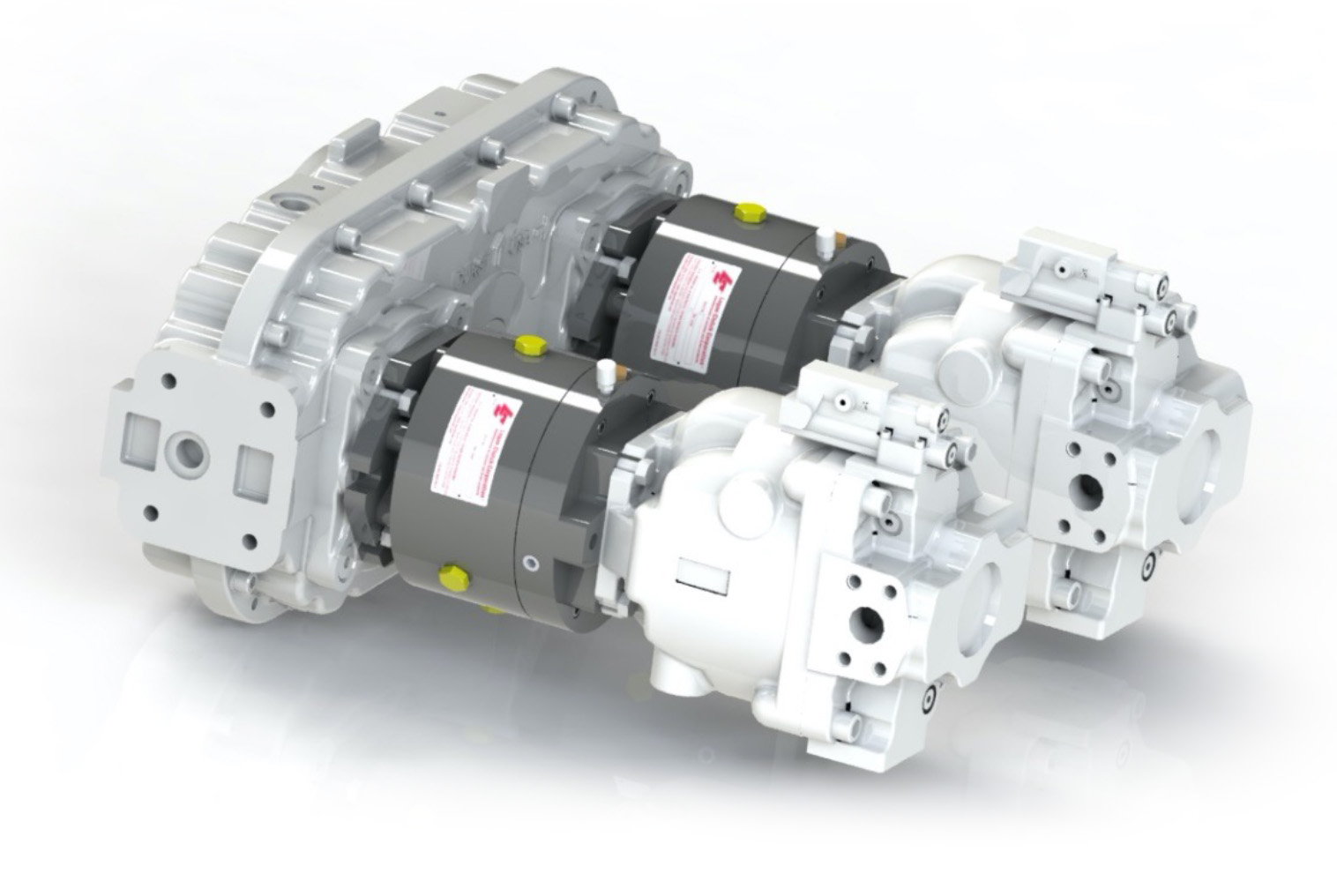

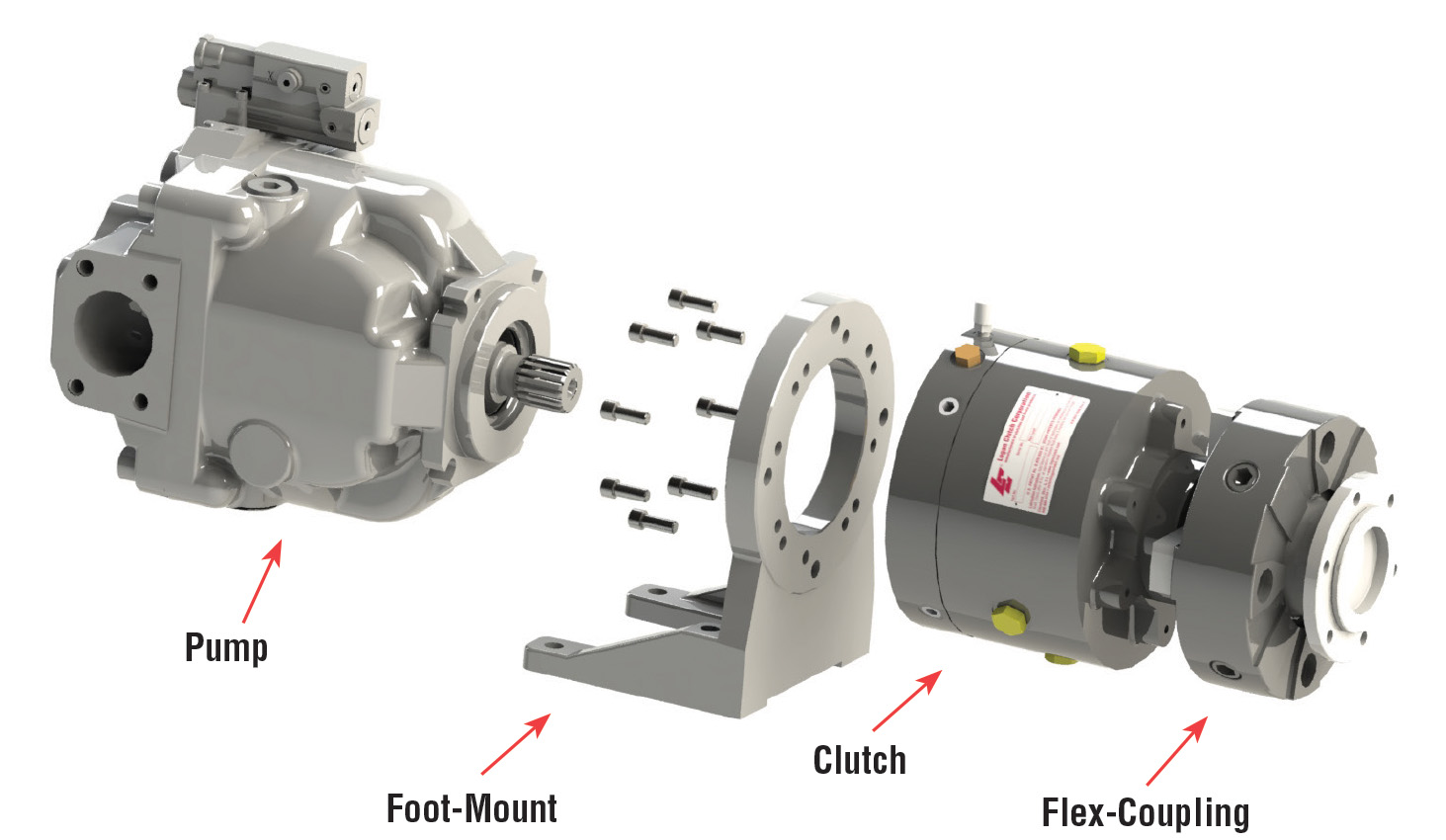

Pump Mount Solution for Low Torsion Applications

For front of engine PTO applications that are rigidly mounted, properly aligned, display relatively low torsional vibration, and are engaged a majority of the time.

- Economical solution

- Short installation length

- Rigidly mounted engines only

- For engines with low torsional vibration

- Best for use in applications that run with clutch principally engaged

- For use with applications with low operational misalignment

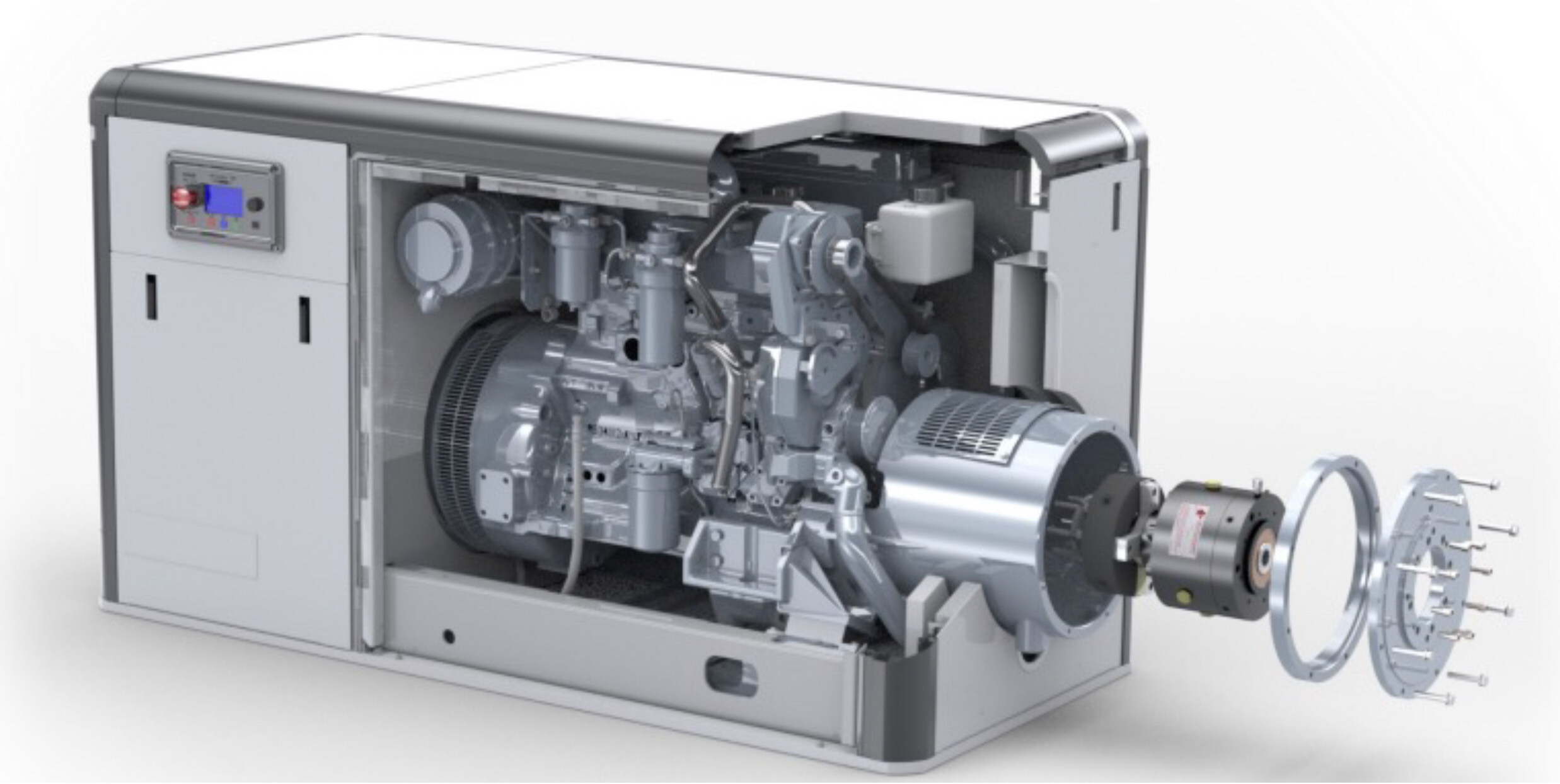

Front of Engine PTO - Engineered Solutions

The ultimate engineered kit solution for OEM applications. Designed in conjunction with the engine OEM, this system provides the most highly engineered front mounting used with any type of engine mounting in a boat. Installation is simply made using only hand tools. The kit allows the engine and front mount package to be pre-assembled in a factory setting and shipped complete for installation into the boat. Total cost of installation can be lowest with this type of front mount kit as it requires the least amount of custom design work at the time of installation.

Advantages:

- Soft or rigidly mounted engines

- Simple installation procedure

- For installations that require maximum torsional vibration protection

- Used in applications that run with clutch engaged or disengaged

- Attachment to engine minimizes operational misalignment

- Engineered kit speeds installation

Logan factory engineered front of engine PTO clutch kits for gensets with sound enclosures. Designed for maximum input and quiet operation.

Overhung Load Adapters:

(OHLA) Shaft adapters are also available for common Dana or DIN style flanges.

SAE and ISO Flanges:

Available in SAE or ISO mounting flanges, with B,C,C-C,D/E and F Splines, plus bore and keyway configurations.

Contact Our Sales Team

Our Sales Engineers can help you find the exact product or service you need to succeed.