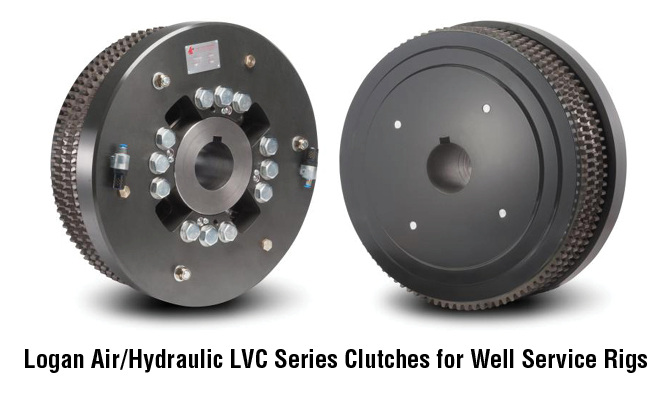

LVC Series Clutches

Clutches for Well Service and Workover Rigs

Logan, Air Actuated clutches for Well Service Rigs and Workover Rigs, have a unique cylinder-piston design, which is lighter in weight, and eliminates air tube diaphragms. The Logan LVC series clutch is an air activated, multiple disc, dry disc pack design, which transfers, smooth, maximum torque transmission within a relatively short axial length. Release Springs within the LVC clutch disc pack ensures consistent, reliable disengagement. Reinforced friction discs provide improved shear and flexural strength over industry standards.

Single Source for Power:

Imagine a new or repowered vessel where the main engines provide propulsive power and drive electric generators, bow thrusters, and mission-specific equipment. What's more, they also provide back-up and redundancy for critical-vessel systems. The Logan FlexaDrive and FlexaGen make this possible.

Where Used:

- Drawworks and Marine Deck Winches

- Workover Rigs / Mobile Drilling for Oil & Gas

- Industrial and Mining Applications

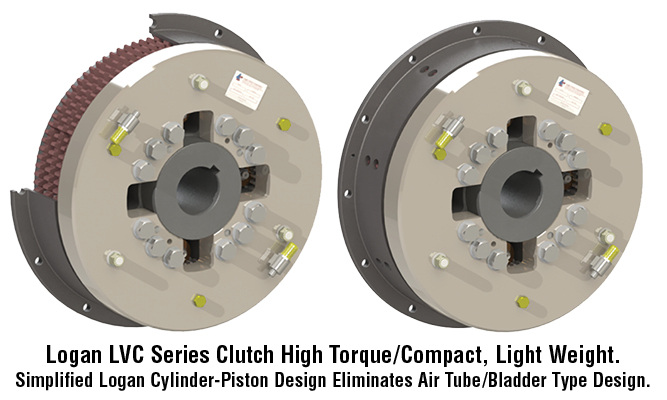

Features and Benefits:

- Air actuated, multiple disc, dry disc pack design for maximum torque transmission within short, axial envelope

- Simplified cylinder-piston, o-ring design, eliminates air tube or bladder type leaks, providing maximum performance in cold and hot operating conditions.

- Piston 'wiper' feature maintains a clean sealing surface for piston seals

- Ventilated drive ring (optional on some models) for additional cooling of the disc pack

- Reinforced friction disc(s) for improved shear and flexural strength over industry standard

- Mechanical emergency screw engagement standard on all models

- Reduced overall unit weight over industry standard

- Plate separator feature to minimize drag between friction disc elements

- Compact design enables larger bore and shaft sizes over industry standard

The Logan LVC cylinder-piston, and O-ring design eliminates the need for air tubes and bladders, which are prone to leaking in hot and cold operating conditions. Plus, our cylinder-piston “wiper” feature maintains a clean sealing surface for piston seals. Larger bore accommodates larger shaft sizes over industry standard.

Maximum Torque – Minimum Envelope – Reverse Compatibility

The Logan LVC clutch cylinder-piston, and disc pack design provides more clamping force and 10% more torque transfer than competitor clutches – all within a design envelope that is reverse compatible and significantly lighter in weight than Twin Disc™, Wichita and WPT type PO Clutches.

Lightweight Design – Ideal for overall rig weight reduction requirements

The Logan LVC design can reduce overall rig weight by several hundred pounds, which goes a long way when complying with state and federal on-highway load regulations during rig transport from job to job.

Torque Ranges

81,000 lb.in. to 768,000 lb. in. @ 100-130 psi

9,000 Nm to 86,000 Nm @ 7-9 bar

Principals only. Recruiters, do not contact. Do NOT contact us with unsolicited services or offers.

Machinists, we want to talk to you. Send your e-mail message and resume to HR@loganclutch.com

Need help finding the right product?

Let our team of Sales Engineers work side-by-side with you to identify the correct product or service that best suits your application.