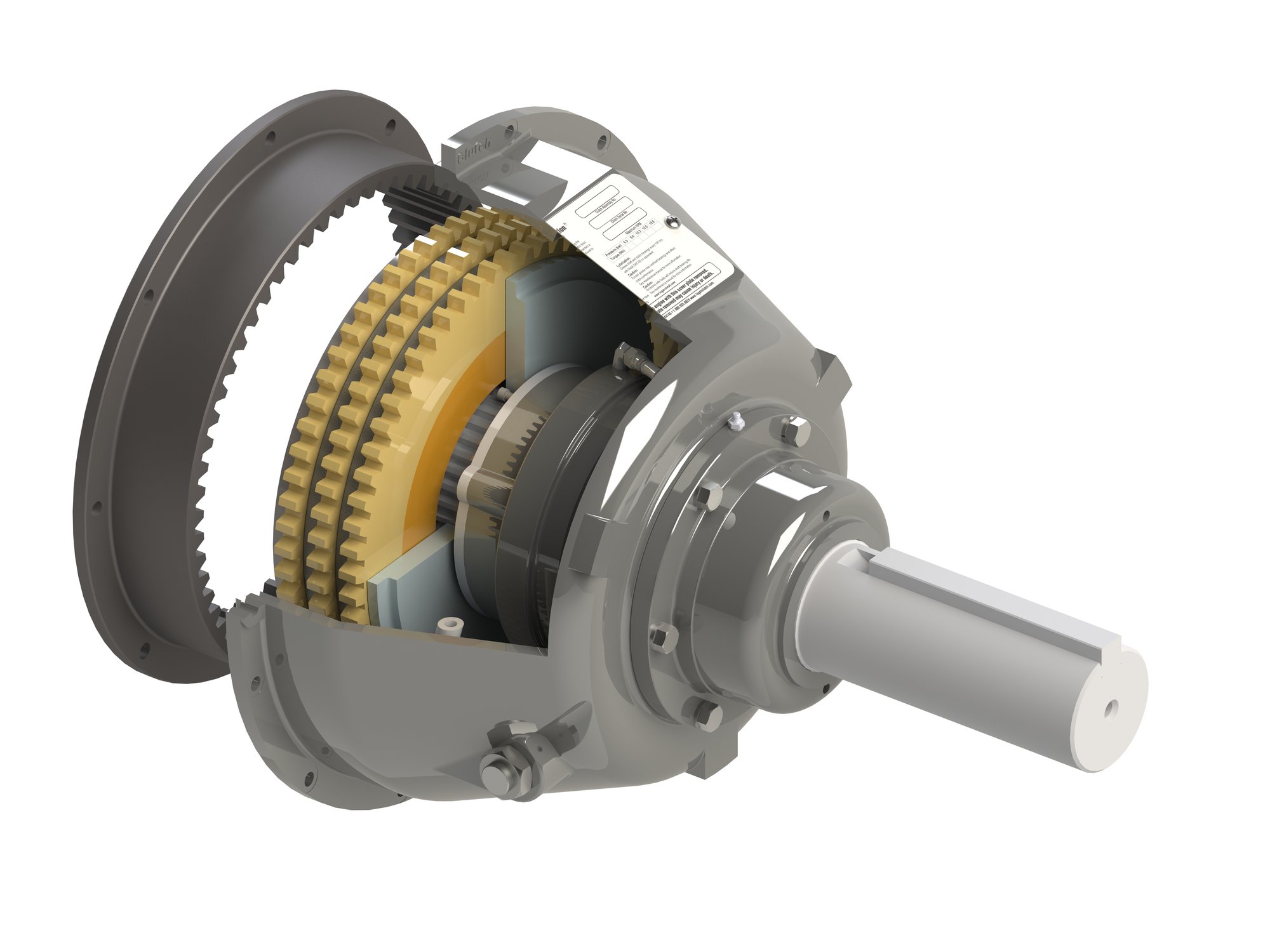

Generation III - Over Shaft Actuation without Pilot Bearing

Logan Generation III Bell Housing PTO Series Description:

Air of Hydraulically actuated and designed to mount to a diesel or gasoline engine’s flywheel. The clutch is bored and key seated for shaft mounting. Torque is transferred from the disc pack to a geared drive ring which is attached to the engine’s flywheel. Gen. III clutches do not require a pilot bearing.

Logan Bell Housing PTO’s - How They work:

Pressurizing the cylinder, forces the piston to clamp and lock the friction and steel separator discs. When pressure is removed, release springs separate the friction and steel separator discs, maintaining a running clearance when disengaged.

Where Used:

- Diesel or Gasoline Engine Powered Equipment

- Industrial Drives / Gensets

- Mobile Equipment

- Blowers, Vacuums, Fans

- Leaf and Debris Collection

- Tree and Brush Chippers

- Snow Removal Equipment

- Marine Propulsion and Auxiliary Gensets

Advantages:

- Air or Fluid Actuated for Remote, Sofstart® Activation

- Self-Adjusting Disc Pack

- Over shaft actuation – no rifle drilling of shaft required

- Pilot Bearing – Field retrofits within existing mechanical PTO’s

- Release springs in disc pack maintain running clearance during disengagement

- For in-line and side load applications

Push Button Actuation – Eliminates Mechanical Linkages

Self-adjusting piston travel compensates for any disc wear, eliminating the need for mechanical adjustment (i.e. levers, linkages, and yokes). The amount of hydraulic or pneumatic pressure applied, regulates the amount of torque transmitted through the clutch. Push-button, remote activation is now possible.

Over-Shaft Actuation:

Since the clutch is designed for over shaft actuation, rifle and cross drilling the shaft is not required.

Standard Specifications:

Standard Logan Bell Housing PTO’s are available in SAE No. 7 to No. 00 Bells, with input torque ranges from 159 lb. ft. ( 216Nm) to over 7,473 lb. ft. (10133 Nm).

Operating speeds range from 1 to 3,000 RPM.

Actuation Pressures:

Air or hydraulic operating pressures range from 100 psi. (6,9 bar) to 200 psi. (13,8 bar) for Generation I and Generation III models and 320 psi. (23 bar) for Generation II Models.

Modified Standards:

Higher Horsepower, torque ranges, speeds, actuation pressures, shaft lengths and design configurations are available to meet customer’s specific design requirements.

Contact Our Sales Team

Our Sales Engineers can help you find the exact product or service you need to succeed.