Static Torque Ratings

Selection Procedure

I. Calculate the torque requirement for the application using one of the following formula:

II. Identify which service factor best identifies your application from the suggested service factor table located at the bottom of this page.

III. Adjust the torque requirement using the selected service factor. T= Tc . SF or T=Tb . SF

IV. Decide which series best fits your drive.

V. Using the appropriate series torque pressure graph, determine the model size.

Vl. Determine if the Series and models can:

- Accommodate the shaft and key

- Operate at the required speed

- Fit within the available space

Vll. Determine the Drive Cup Mounting

Vlll. Call or fax Logan Clutch Corporation to review your selection and place your order. Application fact sheets are available online or from Logan Clutch.

HP = Horsepower

RPM = Clutch or Brake shaft speed

SF = Service Factor

T= Required Torque (Ib ft.)

Tb = Brake Torque (Ib. ft.)

Tc = Clutch Torque (Ib. ft.)

t = Time to stop (seconds)

WK2 = Total inertia to be stopped

(Ib.ft.2)

R Series Wet Operation

Model |

PSI (Ratings in ft. lbs.)* |

Bar (Ratings in Nm) |

||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 50 | 75 | 100 | 125 | 150 | 175 | 3.4 | 5.2 | 6.9 | 8.6 | 10.3 | 12.1 | |

| 350 | 45 | 81 | 117 | 152 | 188 | 224 | 61 | 110 | 159 | 206 | 255 | 304 |

| 450 | 90 | 160 | 229 | 299 | 369 | 438 | 122 | 217 | 311 | 405 | 500 | 594 |

| 550 | 151 | 263 | 376 | 488 | 601 | 713 | 205 | 357 | 510 | 662 | 815 | 967 |

| 600 | 234 | 394 | 554 | 714 | 874 | 1034 | 317 | 534 | 751 | 968 | 1185 | 1402 |

| 700 | 345 | 566 | 788 | 1009 | 1230 | 1451 | 468 | 767 | 1069 | 1368 | 1668 | 1968 |

| 800 | 460 | 773 | 1085 | 1398 | 1711 | 2023 | 624 | 1048 | 1471 | 1896 | 2320 | 2743 |

| 900 | 233 | 753 | 1272 | 1792 | 2311 | 2831 | 316 | 1021 | 1725 | 2430 | 3134 | 3839 |

* Maximum recommended operating pressure 150 PSI (10.3) BAR

S Series Wet Operation

Model |

PSI (Ratings in ft. lbs.)* |

Bar (Ratings in Nm) |

||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 50 | 75 | 100 | 125 | 150 | 175 | 3.4 | 5.2 | 6.9 | 8.6 | 10.3 | 12.1 | |

| 250 | 22 | 39 | 57 | 74 | 91 | 109 | 30 | 53 | 77 | 100 | 123 | 148 |

| 300 | 32 | 57 | 82 | 106 | 131 | 156 | 43 | 77 | 111 | 144 | 178 | 212 |

| 350 | 52 | 81 | 130 | 169 | 208 | 247 | 71 | 110 | 176 | 229 | 282 | 967 |

| 400 | 63 | 117 | 171 | 225 | 279 | 333 | 85 | 159 | 232 | 305 | 378 | 452 |

| 450 | 102 | 178 | 253 | 329 | 404 | 480 | 138 | 241 | 343 | 446 | 548 | 651 |

| 550 | 192 | 325 | 459 | 592 | 725 | 858 | 260 | 441 | 622 | 803 | 983 | 1163 |

| 600 | 281 | 465 | 648 | 832 | 1015 | 1198 | 381 | 631 | 879 | 1128 | 1376 | 1624 |

| 700 | 427 | 700 | 973 | 1246 | 1519 | 1792 | 579 | 949 | 1319 | 1690 | 2060 | 2430 |

| 800 | 511 | 849 | 1187 | 1525 | 1863 | 2201 | 693 | 1151 | 1610 | 2068 | 2526 | 2985 |

| 900 | 854 | 1422 | 1990 | 2559 | 3127 | 3695 | 1158 | 1928 | 2698 | 3470 | 4240 | 5010 |

* Maximum recommended operating pressure 150 PSI (10.3) BAR

P Series Dry Operation

Model |

PSI (Ratings in ft. lbs.)* |

Bar (Ratings in Nm) |

||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 60 | 70 | 80 | 90 | 100 | 4.1 | 4.8 | 5.5 | 6.2 | 6.9 | |

| 350 | 97 | 119 | 141 | 164 | 186 | 132 | 161 | 191 | 222 | 252 |

| 450 | 189 | 232 | 276 | 319 | 362 | 256 | 315 | 374 | 433 | 491 |

| 550 | 351 | 427 | 503 | 579 | 655 | 476 | 579 | 682 | 785 | 888 |

| 600 | 507 | 612 | 716 | 821 | 926 | 687 | 830 | 971 | 1113 | 1256 |

| 800 | 1130 | 1367 | 1603 | 1840 | 2077 | 1532 | 1854 | 2174 | 2495 | 2816 |

*P torque values based on dry operating conditions.

Maximum recommended operating pressure 100 PSI (6.9) BAR

Suggested Service Factor Table

Duty |

SF |

|---|---|

| Small inertia Low Cycle Rate Non-pulsating Load |

1.3 to 1.7 |

| Large inertia Low Cycle Rate Non-pulsating Load |

1.7 to 2.2 |

| Large inertia High Cycle Rate Pulsating Load |

2.2 to 3.2 |

*P torque values based on dry operating conditions.

Maximum recommended operating pressure 100 PSI (6.9) BAR

A pressure regulator should be specified in the system to prevent over-pressurization of any Logan Clutch. The Logan warranty does not cover clutch failure due to over-pressurization. The highest pressure values in the torque tables are maximum ratings for Logan Clutches.

Example: Select a wet environment clutch

HP = 150

Clutch Speed = 800 RPM

Service Factor= 1.3

Available operating pressure = 150 psi.

T = 984 . 1.3 = 1280 lb. ft.

Choose model 800 in the R or S series.

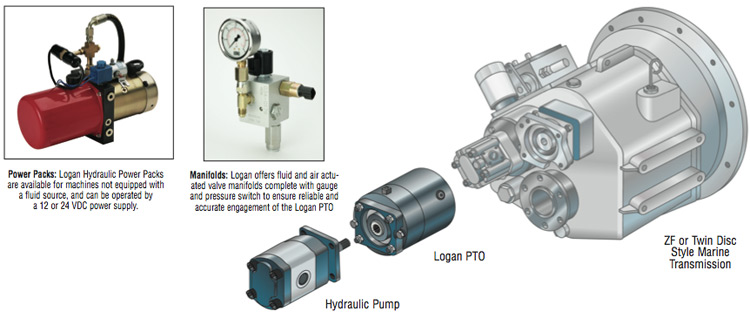

Features:

- Hydraulic Actuation.

- The low profile, compact, Logan PTO design is suitable for workboats, fishing boats and pleasure craft.

- The Logan PTO aids in the reduction of emissions, energy, fuel costs and wear and tear on auxiliary attachments.

- Field retrofits with existing Twin Disc® style and ZF® style live PTO transmissions.

Advantages:

- During Maneuvering – which requires reduction of main engine speed, the Logan PTO is used as a separate power source for bow and stern thrusters.

- The PTO directly connects to a pump drive, which powers winches, reels, hoists, and deck pressure washers.

- The PTO can be coupled to an alternator to supply electric power to other power consumers on the vessel.

PTO 200 Specifications

Dimensions

|

SAE FACE

(input & output) |

B 4-bolt pattern |

B2 |

4 in

101.6 mm

|

F |

6.25 in

158.8 mm

|

| SAE SPLINE |

B/13T/16-32 DP

Input & Output

|

C1 |

0.38 in

9.7 mm

|

G |

0.53 in

13.5 mm

|

| A1 |

1.62 in

41.2 mm

|

C2 |

0.50 in

12.7 mm

|

H |

3.537 in

89.8 mm

|

| A2 |

1.88 in

47.7 mm

|

D |

7.22 in

183.4 mm

|

||

| B1 |

3.999 in

101.6 mm

|

E |

1.22 in

31.0 mm

|

PTO 200 Specifications

| U.S. | S.I. | |

|---|---|---|

| Rated Torque (Maximum) | 200 Ft.Lbs | 271 Nm |

| Maximum HP | 100 HP | 75 KW |

| Maximum RPM | 2800 RPM | 2800 RPM |

| Rotation | Bi-rotation | Bi-rotation |

| Maximum Actuation Pressure | 350 psi | 24 Bar |

| Minimum Actuation Pressure | 250 psi | 17 Bar |

| Displacement (Maximum) | 1.0 in3 | 16,4 cm3 |

| Minimum Flow Rate Required | 1.5 GPM | 5.6 Liters/min |

| Operating Media at Clutch (Oil or Air) | Standard | Standard |

| Maximum Back Pressure to Tank | 7 psi | 0.5 Bar |

| Maximum Fluid Temperature | 180° F | 82° C |

| Material - Shaft | Alloy Steel | Alloy Steel |

| Material - Housing | Aluminum | Aluminum |

| External Finish - Shaft | Alloy Steel | Alloy Steel |

| External Finish - Housing | Anodized | Anodized |

| Wet input seal (Standard) | 30 psi | 2 bar |

| Weight (Approximate) | 15 Lbs | 6.8 Kg. |

* Consult Logan for applications that require lower actuation pressure or increased torque and rpm requirements.

The torque capacity of the clutch is directly proportional to the operating pressure. Maintaining the lowest pressure possible to transfer the desired torque will enable the clutch to run cooler and extend the life span of the internal bearings.

Important: The SBB-200 Series Direct Drive PTO has been specially designed to actuate at higher pressures, (250-350 psi.) than the PTO-250, PTO- 500, and PTO-750 series clutches; which actuate between 80-120 psi.

Horsepower Required to Drive Hydraulic Pump

| HP | 25 | 50 | 75 | 100 |

| Pump Size (GPM) | 20 | 40 | 60 | 80 |

* HP = PSI x GPM / 1371.2 (1714 x 80% efficiency = 1371.2)

* 1 HP is required for each 1 GPM @ 1500 psi.

PTO 200 Series Static Torque Ratings

Bar (Ratings in ft. lbs.) |

|||

|---|---|---|---|

| Model | 250 | 300 | 350 |

| 200 | 240 | 295 | 350 |

PTO 200 Series Static Torque Ratings

Bar (Ratings in Nm) |

|||

|---|---|---|---|

| Model | 17 | 20 | 24 |

| 200 | 325 | 400 | 475 |

PTO 200 Series Shaft Options

Input Shaft/External |

Output Shaft/Internal |

|---|---|

| *SAE B 13T/16-32 D.P. | *SAE B 13T/16-32 D.P. |

| 6B Parallel Side Spline | SAE B 13T/16-32 D.P. |

| .875 O.D. with .250 Keyway | .875 I.D. with .250 Keyway |

| .875 O.D. with .250 Keyway | SAE B 13T/16-32 D.P. |

| SAE B 13T/16-32 D.P. | .875 I.D. with .250 Keyway |

*Standard configuration. Modified Standards available.

ZF is a registered trademark of ZF®

Contact Our Sales Team

Our Sales Engineers can help you find the exact product or service you need to succeed.