SAE PTO 400 Series Specifications

Dimensions

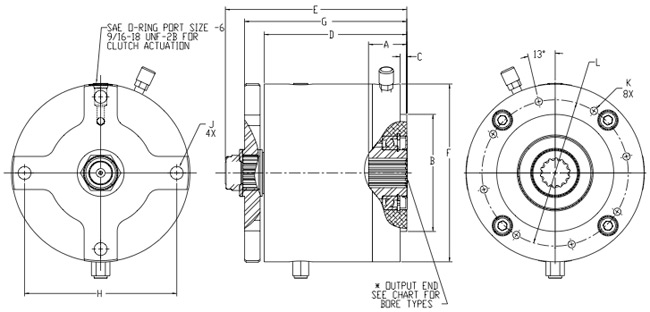

| Mounting Face (input) |

None | D | 6.09 in 154.7 mm |

J | M16 x 2 |

| Mounting Face (output) |

See B, L, K dimensions |

E | 7.75 in 196.9 mm |

K | 3/8-16 UNC |

| A | 1.62 in 41.2 mm |

F | 7.59 in 192.8 mm |

L | 6.250 in 158.8 mm |

| B | 4.999 in 127 mm |

G | 6.93 in 176 mm |

||

| C | 0.28 in 7.1 mm |

H | 6.50 in 165.1 mm |

PTO 400 Specifications

| U.S | S.I. | |

|---|---|---|

| *Rated Torque (Maximum) | 400 Ft/Lbs | 524 Nm |

| Maximum HP | 180 HP | 134 KW |

| *Maximum RPM | 2400 RPM | 2400 RPM |

| Rotation | Bi-rotation | Bi-rotation |

| Maximum Actuation Pressure | 100 psi | 6.9 Bar |

| Minimum Actuation Pressure | 80 psi | 5.5 Bar |

| Displacement (Maximum) | 4.3 in3 | 74 cm3 |

| Minimum Flow Rate Required | 1.5 GPM | 5.6 Liters/min |

| Operating Media at Clutch (Oil or Air) | Standard | Standard |

| Maximum Back Pressure to Tank | 7 psi | 0.5 Bar |

| Maximum Fluid Temperature | 180º F | 82º C |

| Material - Output Hub | Alloy Steel | Alloy Steel |

| Material - Housing | Aluminum | Aluminum |

| External Finish - Output Hub | Alloy Steel | Alloy Steel |

| External Finish - Housing | Anodized | Anodized |

| Weight (Approximate) | 29 Lbs | 13 Kg |

* Consult Logan for applications that require lower actuation pressure or increased torque and rpm requirements.

Important: The PTO 400 Series Direct Drive PTO has been specially designed to actuate at lower pressures (80-100 psi) than the PTO-250, PTO-500, and PTO-750 series clutches; which actuate between 80-120 psi.

The torque capacity of the clutch is directly proportional to the operating pressure. Maintaining the lowest pressure possible to transfer the desired torque will enable the clutch to run cooler and extend the life span of the internal bearings.

PTO 400 Series Static Torque Ratings

PSI (Ratings in ft. lbs.) |

|||

|---|---|---|---|

| Model 400 |

80 | 90 | 100 |

| 404 | 462 | 520 | |

PTO 400 Series Static Torque Ratings

BAR (Ratings in Nm) |

|||

|---|---|---|---|

| Model 400 |

5.5 | 6.2 | 6.9 |

| 548 | 625 | 705 | |

PTO 400 Series Pump Shaft Options

| Part No. | Output Description |

|---|---|

| SPF-4000 | SAE ‘C’ spline 14T 12/24 DP |

| SPF-4001 | SAE ‘B’ spline 13T 16/32 DP |

| SPF-4002 | 1.250 dia. with 5/16” keyway |

Notes: The output end of the clutch (female spline/bore) is not capable of supporting any side load. Use overhung load adapters.

Contact Our Sales Team

Our Sales Engineers can help you find the exact product or service you need to succeed.