Clutches for Pumping Stations

The Challenge:

Many pumping stations use Twin Disc style mechanical clutches, a technology that has remained practically unchanged since the 1940s. Mechanical clutches require manual engagement via a lever arm that is usually in a position that is difficult to operate.

Further, as the clutch plates wear, the pressure provided by the lever arm is no longer enough to engage properly, so operators must remove a cover plate and adjust the plates to ensure proper torque transfer during operation. In addition to the added labor of manual engagement and adjustment, failure to properly maintain the clutch can cause failure of the clutch, which could be devastating in an application like flood water pumping stations where reliability is so important.

The Logan Solution:

Logan Bell Housing PTO’s are self-adjusting and activated via pneumatic or hydraulic pressure. The Logan Bell-Housing PTO clutches easily fit within the same envelope space of the mechanical clutches, while eliminating the need for manual adjustment and engagement. The pneumatic or hydraulic actuation allows the clutch to be engaged and disengaged with push-button controls or remotely through wireless controls.

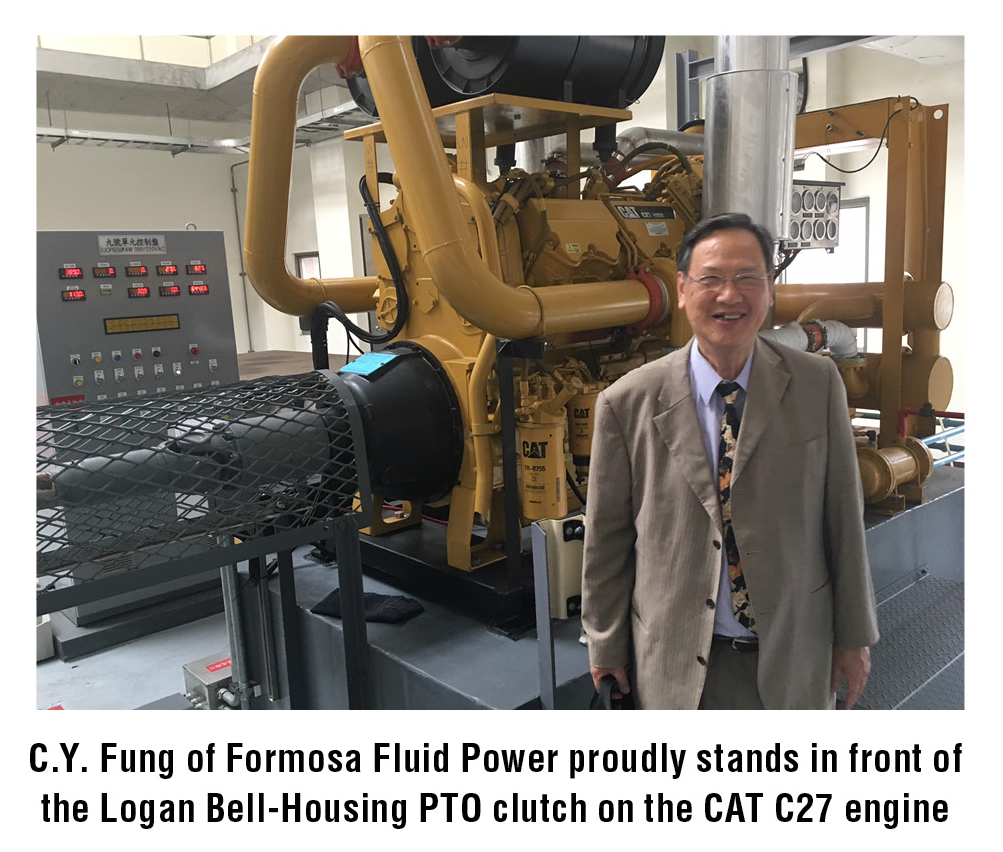

These improvements provide the pumping station with the reliability needed to meet the demands of pumping excess water in emergency situations, ensuring public safety. According to C.Y. Fung of Formosa Fluid Power, “The pumping station appreciates the simplified push-button engagement of the Logan clutches over the lever arm of the mechanical clutches.” The Mechanical clutches were never properly adjusted – with the Logan self-adjusting Bell Housing PTO’s, the pumps run on demand, through push-button activation

The Jingmei pumping station uses a lineup of CAT engines with Logan Bell-Housing PTO clutches to power their pumps