Bell Housing PTO Water Jetting Systems

Trailer or Skid Mounted Blasting Systems

Trailer or Skid Mounted Blasting Systems

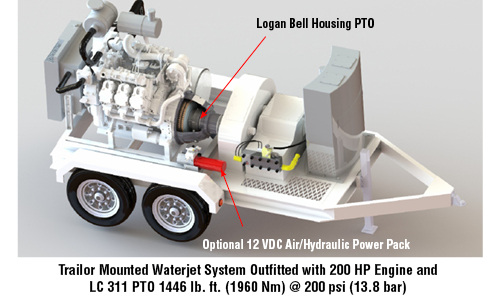

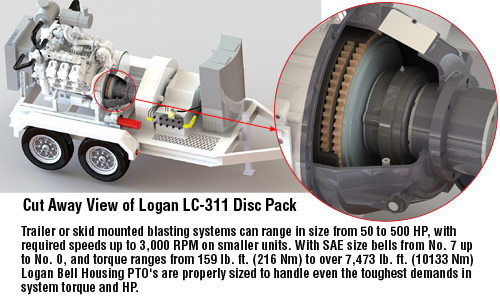

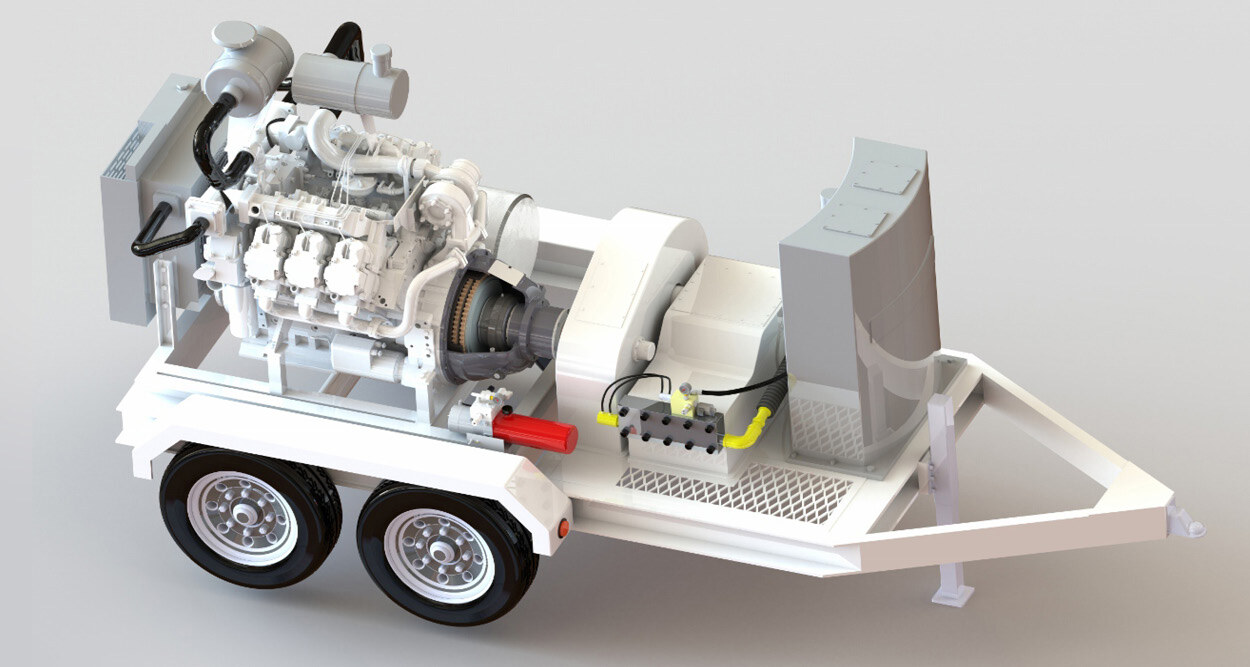

Trailer or skid mounted blasting systems can range in size from 50 to 500 HP, with required speeds up to 3,000 RPM on smaller units. With SAE size bells from No. 7 up to No. 0, and torque ranges from 159 lb. ft. (216 Nm) to over 6,000 lb. ft. (8236 Nm) Logan Bell Housing PTO's are properly sized to handle even the toughest demands in system torque and HP.

Where Used:

- Diesel or Gasoline Engine Powered Equipment

- Industrial Drives / Gensets

- Mobile Equipment

- Blowers, Vacuums, Fans

- Leaf and Debris Collection

- Tree and Brush Chippers

- Snow Removal Equipment

- Marine Propulsion and Auxiliary Gensets

Advantages:

- Air or Fluid Actuated for Remote, Sofstart® Activation

- Self-Adjusting Disc Pack

- Over shaft actuation – no rifle drilling of shaft required

- Pilot Bearing – Field retrofits within existing mechanical PTO’s

- Release springs in disc pack maintain running clearance during disengagement

- For in-line and side load applications

Trailor mounted waterjet system outfitted with 200 HP engine and LC 311 PTO 1446 lb. ft. (1960 Nm) @ 200 psi (13.8 bar)

Cut away view of Logan LC-311 disc pack

Logan vs. Mechanical PTO’s

The advantage of the Logan Clutch is its ability to engage and disengage the water jetter hydraulically, through push-button activation, eliminating the use of a mechanical hand lever or yoke type clutch engagement system, which dates back to the early 40’s. Smooth, Logan SOFTSTART engagement eliminates clutch downtime due to over and under adjustment. And since the Logan clutch is self-adjusting, clutch engagement is smooth and consistent after hundreds of hours of use.

The mechanical clutch requires the operator to “hand engage” a clutch, which opens up the opportunity for untrained operators to slam the clutch into gear at high rpm’s. Another mode of failure is when operators will over or under tighten the adjusting collar on mechanical clutch to the point where the clutch is too loose and slips to failure or is over tightened and never disengages. Unfortunately, this happens during operating conditions, forcing the water jetter to return to the rental yard, leading to unproductive downtime, inconsistent operation and the endless frustration of machine renters, service center owners, and mechanics.

Making the Switch from Mechanical to Logan

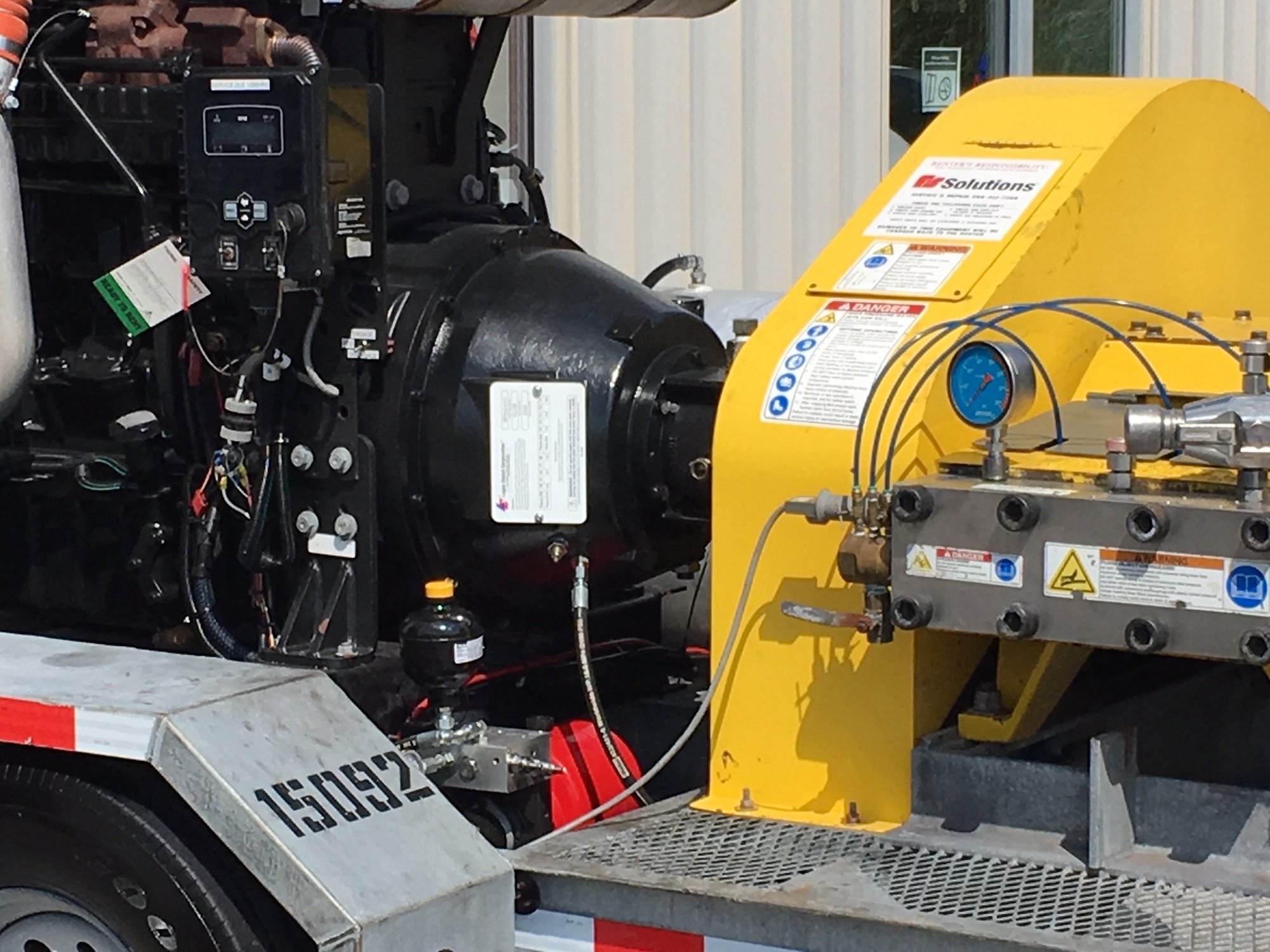

Jetstream / FS Solutions Rental Center Makes the Switch from Mechanical to Logan

“Making the switch was easy”, says Richard Alderson of the FS Solutions, Hammond Indiana Office, “we pulled the old Mechanical Clutch and drive ring, along with all of the linkages, levers and yoke, and replaced the clutch with a Logan RP 314 Series clutch.” The Logan design uses the same shaft, drive ring and taper as the mechanical clutch, making the changeover relatively quick and easy. “All we had to do was install the Logan Bell Housing PTO Clutch, a power pack, and an on/off switch, and within a few hours we were ready for service” says Alderson. Logan Clutch would like to thank FS Solutions, of Hammond, IN for allowing them to retrofit the new self-adjusting PTO on the Jetstream X-Series unit.

Logan Push Button Actuation - Eliminates Mechanical Linkages

Logan clutches are simple to operate. Push-button activation engages the clutch from a control panel or remote operating device. Hydraulic or pneumatic pressure via the Logan hydraulic power pack and maniford, clamps the cylinder and piston inside the clutc

Push button activation from a control panel or device is now possible. Pictured above: Richard Alderson - Jetstream, which then engages the friction and steel separator discs with a Logan

Contact Our Sales Team

Our Sales Engineers can help you find the exact product or service you need to succeed.