Two-Position Pump Drive - 1000 HP

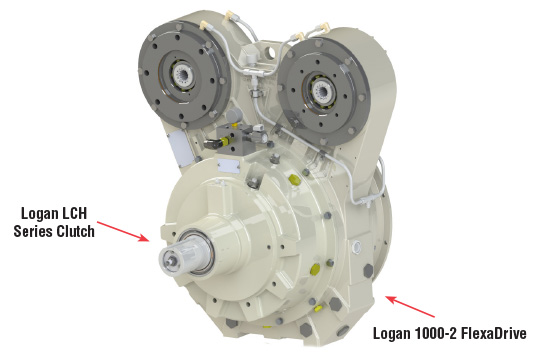

NEW! Logan FlexaDrive™1000-2 Series

2-Position Pump Drive System for Engines up to 1000 HP (745kW)

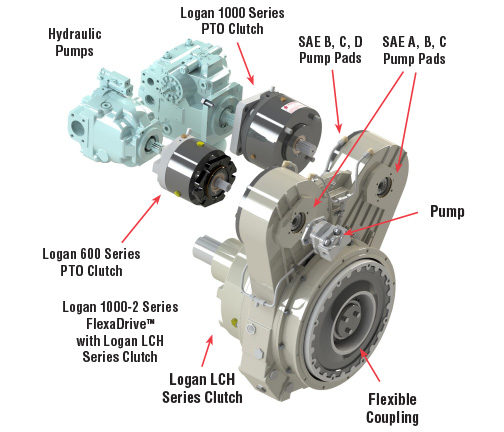

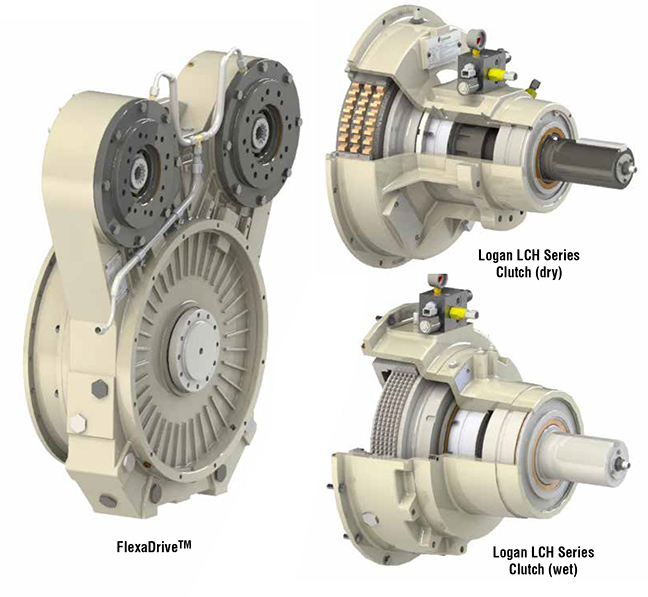

Logan FlexaDrive™ Series Description:

The Logan FlexaDrive multiple pump drive system is a self-contained gearbox with integral flexible coupling, providing full engine power between your engine (power take-off) and transmission. Three (3) different models, with up to five (5) pump drive towers offer up to ten (10) PTO/PTI pump pads with bi-directional rotation for engines ranging from 200 HP (150 kW) to 5000 HP (3700 kW) at a maximum of 2000 RPM (custom configuration available). Various step-up gear ratios are available for direct drive PTO’s. An integral Flexible coupling is part of the system to dampen torsional vibration. Logan FlexaDrives mount to all standard SAE flywheel housings ranging from No. 3 to No. 00.

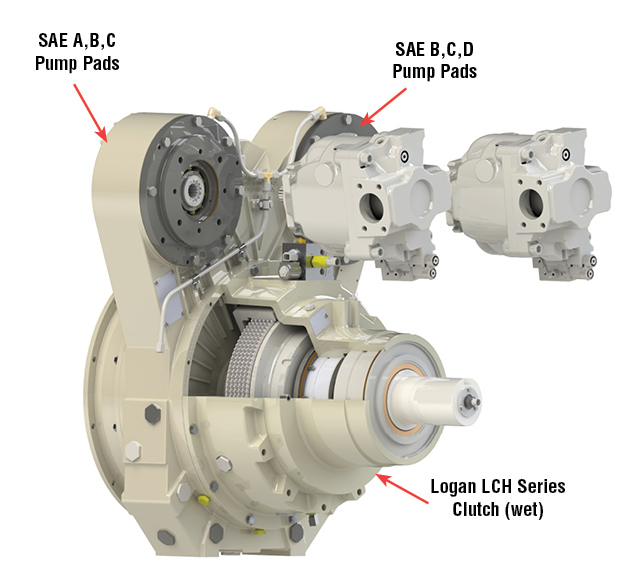

2-position Pump Drive System For Engines up to 1000 HP (745 kw)

The Logan 2-Position Pump Drive is outfitted with up to four (4) PTI / PTO pads, and can accommodate up to 1000 HP (745 kW) Engines, with maximum Speeds up to 2200 RPM, and a maximum of 160 HP (120kW) per tower under continuous duty.

- Input Housing SAE No. 1 – No. 3

- Output Housing SAE No. 1 - No. 3

- Pump Pads SAE A – SAE D

- Continuously Rated – Total 300Hp (225Kw)

- Continuously Rated – Per Tower 160Hp (120Kw)

- Integrated Reservoir - Eliminates need for secondary tank

- Pump Drive Towers can be positioned up to 45º in either direction

Logan Direct Drive Power Take-off (PTO) Clutches

How They Work:

Direct Drive PTO’s are self-contained, fluid or air activated clutches, positioned between a live PTO pad and hydraulic pump.

PTO Clutch Advantages:

- Reduces fuel consumption and CO2 emissions by engaging drives and pumps only when required

- Better Engine Starts: Reduces horsepower draw and cranking power required during machine start-up by disconnecting the hydraulic system from the engine

- Reduced ambient noise through intermittent use of pumps and equipment

- Cooler running hydraulic systems: Heat is generated whenever oil dumps from high to low pressure without producing work. Disconnecting the PTO Clutch reduces the destructive effects of heat – lowering maintenance costs and hydraulic oil service

- requirements

- Extends the life of drive systems and components

- Standard PTO clutches available in A, B, B-B, C, C-C, D and other popular sizes

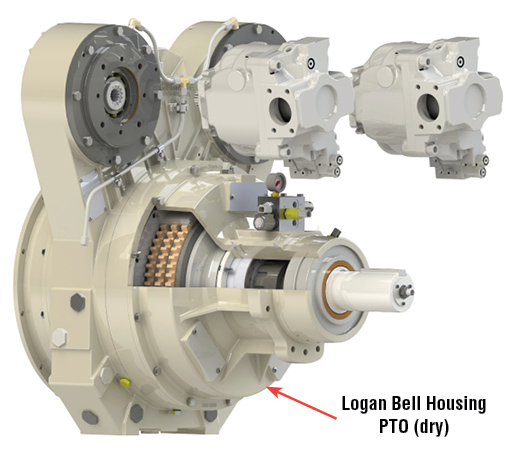

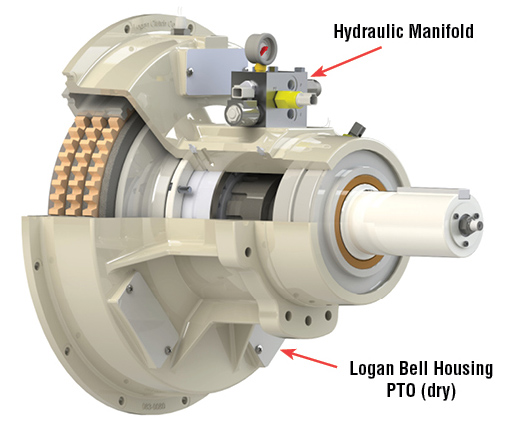

Dry vs. Wet Operation:

Logan offers either wet or dry clutches for our Flexadrives, each with application specific benefits:

Dry Clutch / Moderate Duty: Dry clutches are simpler to operate and maintain, and can perform as well as a wet clutch in moderate operating conditions – and with the addition of lockup detection and speed sensors, Logan dry operating clutches can withstand higher system inertia loads than conventional dry clutches.

Wet Clutch / Heavy Duty: Logan wet clutches operate in an oil bath, which helps dissipate heat. Clutches can either operate in an oil bath with splash oil cooling, or in an oil bath cooled by a heat exchanger. Wet clutches are better suited for heavyduty applications where a moderate slip during initial engagement is required to overcome initial high inertia loads, such as rock crushing or road grinding. The Logan clutch operates in its own oil bath, and is separate from the FlexaDrive gearbox, which eliminates contamination of gearbox oil from friction disc particles.

Contact Our Sales Team

Our Sales Engineers can help you find the exact product or service you need to succeed.