S Series

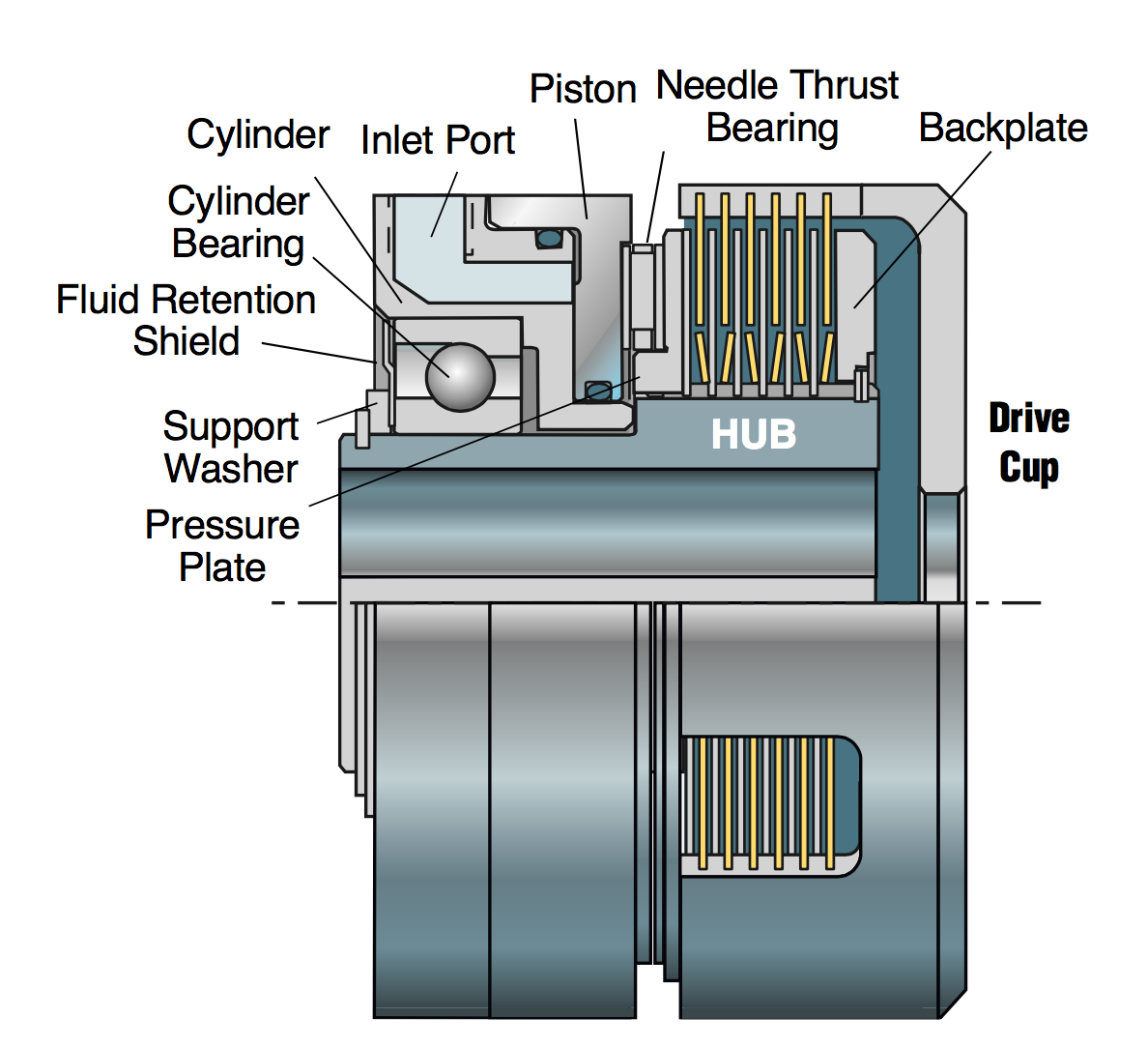

Stationary Cylinder for Precise Alignment

The actuating cylinder and piston in the S series design do not rotate. They are bearing sup-ported on the mounting hub and are held stationary by the external connection to the inlet port.

This bearing allows the separator discs and hub, and the shaft on which it mounts, to rotate about the cylinder and piston. A thrust bearing permits relative motion between the stationary piston and rotating separator discs. Because both bearings require lubrication, it is important to utilize lube ports provided and/or direct an oil spray or splash at bearing surfaces.

Features

- Hydraulic or Pneumatic Actuation

- Wet Operation

- Stationary Cylinder and Piston

- Fast Response / Lower Inertia

- Easy Installation

- Minimal Actuating Flow

- Positive Disengagement

- Can be Modified to Meet Specific Application Requirements

Logan Outperforms Electromagnetic Clutches

Logan has the design and manufacturing capability to replace existing and obsolete electromagnetic clutches with Logan technology.

Logan vs. Electromagnetic Clutches

-

Transmits more Torque and has higher RPM capabilities within the same envelope

-

Eliminates residual DC magnetism in disc packs and bearings-reduces downtime

- Disc Pack, Bearing Kits and Seal Kits for Logan clutches are available from stock

Contact Our Sales Team

Our Sales Engineers can help you find the exact product or service you need to succeed.