900-8301-04

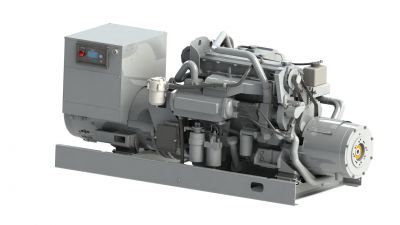

Front of Engine PTO Clutch Kit Kohler John Deere 4045AFM85

Tech Specs:

JOHN DEERE 4045AFM85 ENGINES.

Review Installation, Operation and Maintenace Instructions, Logan P/N 053-0147, for ordering details on Sound Enclosure and SAE PTO Clutch.

SPF 600 Series Clutch Sold Separately. Review Front of Engine Clutch Product Selection for Clutch Torque, Actuation Pressure and Output Shaft Spline Offering.

Clutch Rated at 600 Lbs.-Ft.

SAE 'B' 2/4 Bolt Mounting Face Output

Kit Includes Bracket, Torsional coupling, Rigid coupling and All Hardware.

Part Number:

900-8301-04

Description:

Logan PTO’s are used in a variety of Industrial, On-Highway, Marine, Construction, Agriculture, Mining, Oil Field, and Rail

applications – and are designed to mount between the power take-off of the engine and auxiliary attachment, i.e. single or

multi-station pump drive.

Advantages:

• Reduces fuel consumption and CO2 Emissions by engaging

drives and pumps only when required

• Quicker Starts: Lowers horsepower draw and cranking power

required during machine start-up by disconnecting the hydraulic

system from the engine

• Reduced ambient noise through intermittent use of

pumps and equipment

• Cooler running hydraulic systems: Heat is generated

whenever oil dumps from high to low pressure without

producing work. Disconnecting the PTO Clutch reduces the

destructive effects of heat – lowering maintenance costs and

hydraulic oil requirements

• Extends the life of drive systems and components

Features:

• Air or fluid actuated

• Integrated torsional isolation coupling

• Engineered mounting bracket for precise alignment

• Maximum torque, small envelope, higher engagement

speeds (up to 1800 RPM with SOFTSTART? feature)

• Low profile, compact, design is suitable for workboats,

fishing boats and pleasure craft

• Heavy-duty, self-contained corrosion resistant

design requires no external lubrication

• Smooth engagement / disengagement

• Simplified, compact, high torque design

• Remote activation from a control panel or operator’s station

• Optional manual engagement screws in case power

flow is disrupted

• Optional shaft adapters for Dana style flanges

• Oil bath or flow through cooling