Pick-Off Drives Wickman

Logan Single and 2-Speed Pick-off Drives for Your Screw Machine

- Logan brake stops pick-off spindle rotation just prior to the pick-off collet opening - Parts now eject from a stopped spindle, minimizing nicks and marks and lost parts

- Reduces or eliminates machine lock-ups caused by inconsistent part ejection

- Second speed option for faster back finishing speed - fewer secondary operations

- Retrofits with existing OEM or aftermarket Air Pick-offs

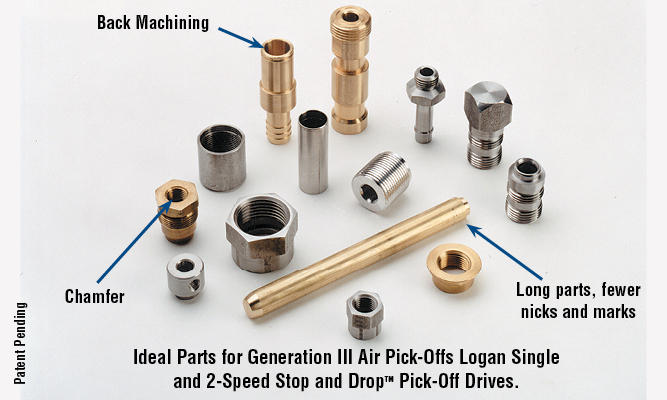

Now, more than ever, screw machine users must find ways to eliminate secondary operations, and increase machine efficiency. Thats why Air Pick-off attachments have been essential in successfully eliminating costly secondary finishing, back machining, recessing, drilling, chamfering and deburring operations.

One drawback to the air pick-off attachment: completed parts eject from the pick-off collet during spindle rotation at speeds well over 1,500 rpm.

This abrupt part cut-off often propels finished parts beyond the parts chute and into the tool zone and chips - creating nicks and marks on the part, and possibly jamming other machine components such as cross slides and attachments.

New Logan Stop and Drop Feature

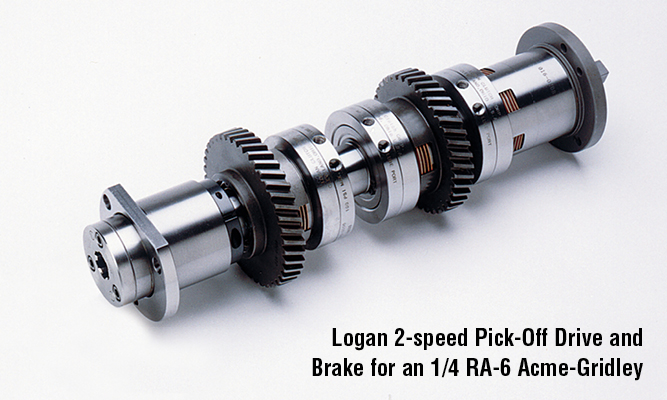

Now Logan makes it easy for you to eliminate inconsistent part ejection, nicks and marks, and

lost parts with our new Single and 2-Speed Stop and DropTM Pick-off drives. With the standard Logan power-applied brake feature, parts eject from a dead spindle right into your parts chute. Our 2nd speed option enables more back finishing speed and machining capabilities up to 45% in many cases.

Typical Air Pick-off Arrangement.

Logan Single and 2-Speed Pick-off Drives for your Screw Machine

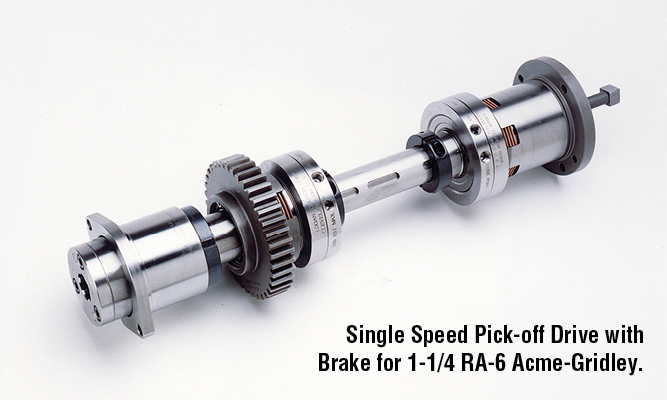

Single Speed Pick-off Drive Features:

- Logan brake stops pick-off spindle rotation just prior to the pick-off collet opening

- Parts now eject from a dead spindle, enabling finished parts to be ejected more reliably and accurately into your parts chute

- Reduces or eliminates machine lock-ups caused by inconsistent part ejection

- Rotational speed is one-to-one with spindle speed

- Hidden savings - fewer good parts are lost in your coolant and chip reclamation system

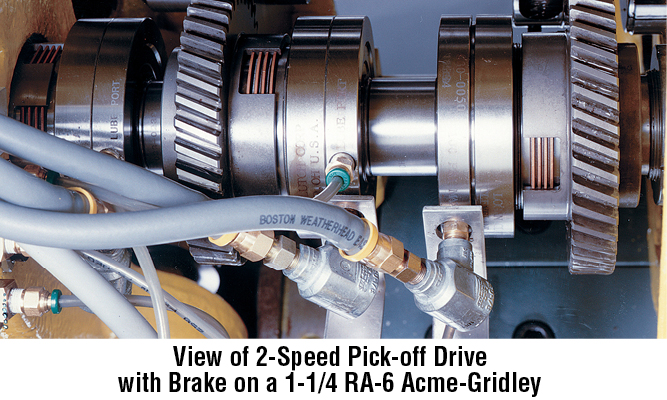

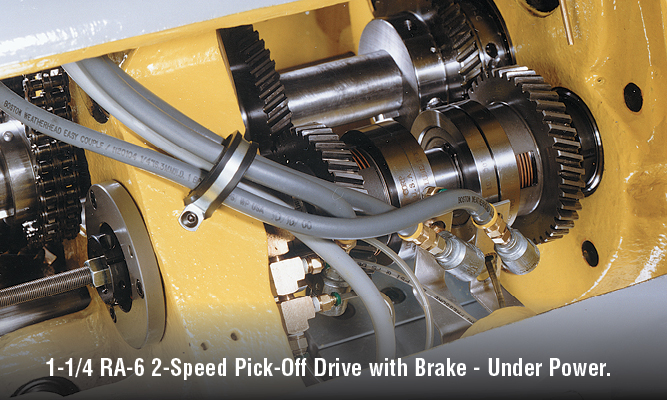

2-Speed Pick-off Drive Features:

-

Eliminates secondary operations Equipped with a second, faster back finishing speed which is useful for back machining or drilling applications

-

Second-speed option provides up to 45% faster RPM than main spindle speeds

Logan Air Pick-Off Control Options

1. Standard Cams and Limit Switches

Feature

- Conventional Cam and limit Switch operation

2. CS 2001XT16 Microprocessor Control

Popular Features

- Easy to read 2-line screen Displays cycle time, parts count, machine position in degrees

- Machine Lockup detection -

- low-speed shift points in degrees

- Thread Check - detects tap failure and shuts down your machine before index

- 15 programmable tool counters

- Eliminates auxiliary cams and limit switches

- Stock Load positioning - reduce stock-up by 50%

3. CS 2001 Microprocessor Control

All the features of the XT16 plus:

- Full pre-wired push-button control station

- Eliminates relay logic

- 35 Programmable Tool Counters

- Air coolant, lube pressure monitor capability

- Plus many more features - call for details

Contact Our Sales Team

Our Sales Engineers can help you find the exact product or service you need to succeed.