Hi-Lo Retrokit Wickman

For Your Early and Late Model Wickmans

Optimize Your Early And Late-Model Wickman With New Logan Hi-Lo Retrokits!

Optimize Your Early And Late-Model Wickman With New Logan Hi-Lo Retrokits!

New Logan Hi-Lo Retrokits for your early and late-model Wickmans increase your machines daily and weekly output from 10-20% - leaving you room for additional capacity, productivity and profitability.

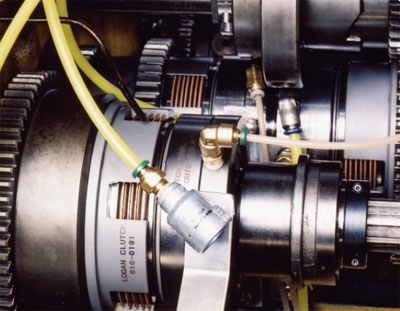

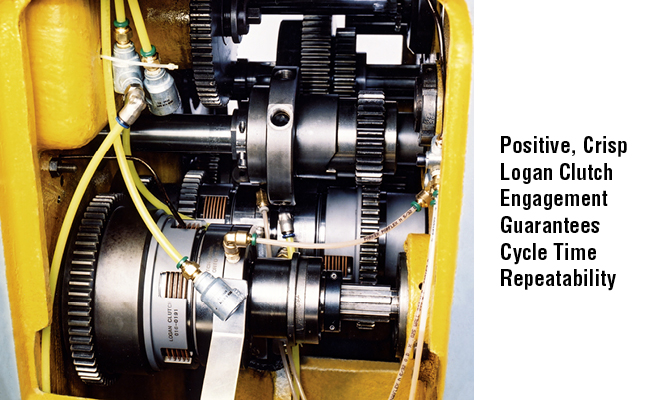

Positive, fast-acting Logan Clutch engagement enables your Wickman to change speeds much faster, and provides a more consistent and accurate cycle time than conventional mechanical and electromagnetic clutches.

Simplifies Machine Set-up

Set-up personnel can position tools closer to the work piece, and reduce dwell time due to repeatable high and low-speed clutch engagement.

Guaranteed Cycle Time Repeatability

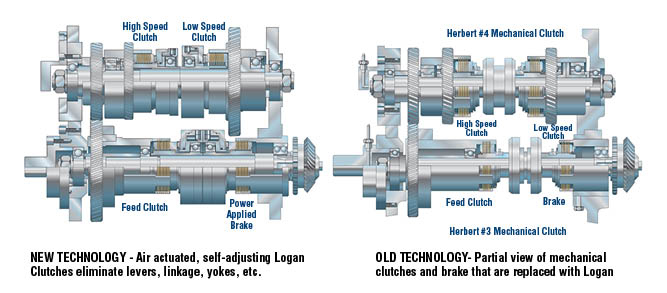

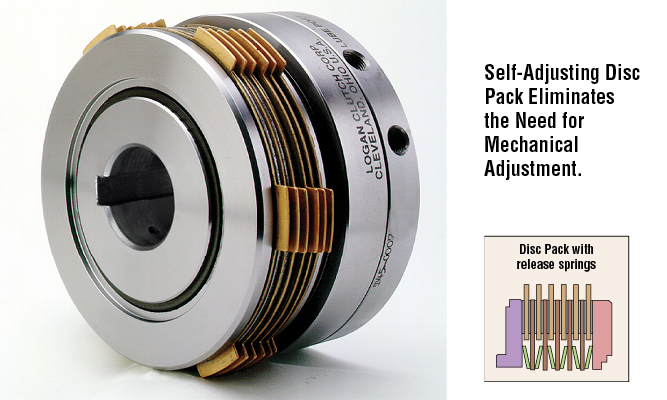

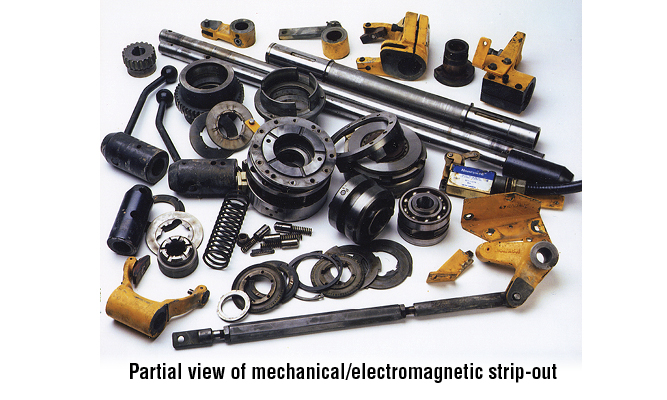

We replace your mechanical and electromagnetic actuated high-speed and feed clutches, brake, linkages, pins and lever arms with air-actuated, self-adjusting Logan clutches. By making the switch from mechanical or electromagnetic to Logan, you'll increase your machines, daily and weekly output significantly, through consistent and accurate speed changes and decreased maintenance.

Ideal for Bar Loaders

Our quick-stop power applied brake prevents coasting and provides accurate braking for

bar loader positioning during feed-out.

Logan Hi-Lo Retrokit for your late model 1-6 Wickman. (Inspection # 15817 and above). Retrokits are available as original equipment, during machine reconditioning or as a field retrofit.

Hi-Lo Retrokit Features

- Reduces idle time between speed changes.

- Replaces mechanical/electromagnetic high speed clutch, feed clutch and linkages with fast-acting air-actuated Logan Clutches, and power applied brake.

- Positive, crisp Logan Clutch engagement guarantees cycle time repeatability. Simplifies clutch maintenance - No disc pack adjustment or slippage.

- Quick-stop, power-applied brake - Prevents machine coasting, minimizes cut-off tool breakage, and optimizes your bar loader investment.

Savings

- Increase productivity from 10-20%.

- Tools can be positioned closer to the work piece due to repeatable high and low-speed clutch engagement.

- Better machine utilization - More productivity from existing machines, operators and floor space.

- Fast acting air actuated Logan clutch engagement enables your late model Wickman to change speeds faster and more consistently

- Tools can can be positioned closer to the work piece due to repeatable high and low speed clutch engagement.

Logan Outperforms Electromagnetic Clutches!

Logan vs. Electromagnetic Clutches

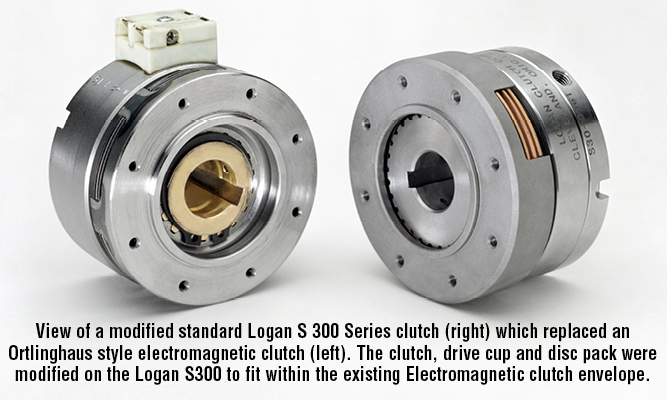

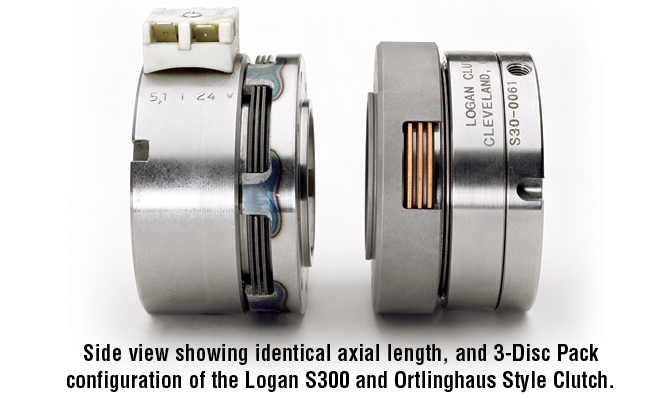

Transmits more Torque and has higher RPM capabilities within the same envelope

Transmits more Torque and has higher RPM capabilities within the same envelope- Eliminates residual DC magnetism in disc packs and bearings - reduces downtime

- Logan Disc Pack, Bearing Kits and Seal Kits are available from stock

Logan has the design and manufacturing capability to replace existing and obsolete electromagnetic clutches with Logan technology

View of a modified standard Logan air actuated clutch (right) which replaced an Ortlinghaus style electromagnetic clutch (left). The clutch, drive cup and disc pack were modified on the Logan to fit within the existing Electromagnetic clutch envelope. Side view showing identical axial length, and 3- disc pack Configuration of the modified Logan and Ortlinghaus style clutch. Ideal for pick-off drives, threading clutches and more for Euroturn / Mori-Say / Gildemeister / Schuttle

Contact Logan today for more details.

Logan Hi-Lo Retrokits

Simple to Install:

- Each Logan Electrical, Mechanical, Pneumatic and Accessory kit is designed to save you time and money during installation.

- Kits are furnished with detailed mechanical, electrical and pneumatic schematics.

- Logan Hi-Lo Retrokits are available as Original Equipment (OEM), during machine reconditioning / rebuilding or as a field retrofit

- Simplifies addition of stock depletion, broken-tool and short-part detectors

- Field installation service is also available

Justification Worksheet For Your Wickman

Production time = 16 Hours/Day (70% Efficiency or Run Time) |

|||

|---|---|---|---|

Wickman 1-6 |

Cycle Time With Mechanical Only |

Cycle Time With Logan Retrokit |

% Increase With Logan Hi-Lo Retrokit |

| Cycle Time (#seconds per part) | 7.00 | 6.30 | 10.0% |

| Parts per minute (x 0.7) | 6.00 | 6.67 | 0.67 |

| Parts per hour | 360.00 | 400.00 | 40.00 |

| Parts per shift (8 hrs.x 0.7) | 2,880.00 | 3,200.00 | 320.00 |

| Parts per day (2 shifts) | 5,760.00 | 6,400.00 | 640.00 |

| Parts per week (5 days) | 28,800.00 | 32,000.00 | 3,200.00 |

| Parts per year (50 weeks) | 1,440,000.00 | 1,600,000.00 | 160,000.00 |

| Revenue @ $0.15 per part | $216,000.00 | $240,000.00 | $24,000.00 |

- Additional parts produced per year - with Hi-Lo Retrokit: 160,000

- Total added revenue / turnover to corporation, utilizing existing machine, operator and floor space $24,000.00

Above calculation based on 10% increase in productivity - Varies by machine vintage

See for yourself - Call today for your Free Logan Hi-Lo Retrokit justification worksheet

Contact Our Sales Team

Our Sales Engineers can help you find the exact product or service you need to succeed.