Hi-Lo Retrokit - BSA

For Your BSA: Now Better Than Ever!

Optimize Your Early And Late-Model BSA With New Logan Hi-Lo Retrokits!

New Logan Hi-Lo Retrokits for your early and late-model BSA's increase your machines daily and weekly output from 10-20% - leaving you room for additional capacity, productivity and profitability. Positive, fast-acting Logan Clutch engagement enables your Acme to change speeds much faster, and provides a more consistent and accurate cycle time than conventional mechanical clutches.

Simplifies Machine Set-up

Set-up personnel can position tools closer to the work piece, and reduce dwell time due to repeatable high and low-speed clutch engagement.

Guaranteed Cycle Time Repeatability

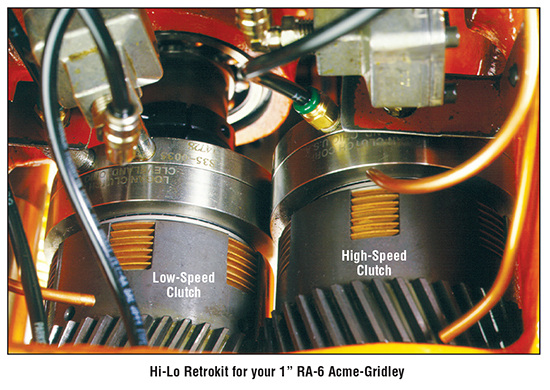

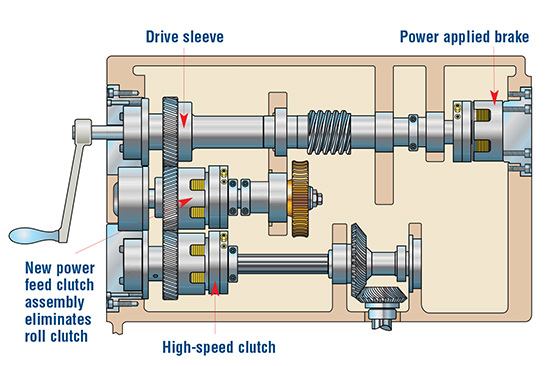

We replace your 1940s vintage mechanically actuated high-speed and feed clutches, roll clutch, band brake, linkages, pins and lever arms with air-actuated, Self-AdjustingTM Logan clutches. By making the switch from mechanical to Logan, you'll increase your machines, daily and weekly output significantly, through consistent and accurate speed changes and decreased maintenance.

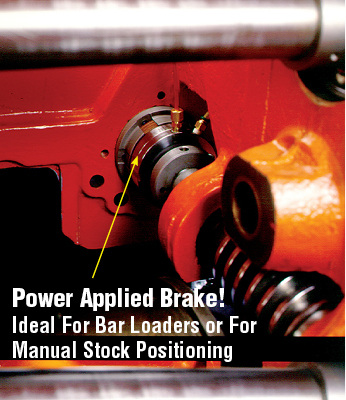

Even better - Our quick-stop power-applied brake prevents coasting and provides accurate braking for bar loader positioning during feed-out.

Hi-Lo Retrokit® Features

- Reduces idle time between speed changes.

- Replaces mechanical clutches, roll clutch, band brake and linkages with fast-acting air-actuated Logan Clutches.

- Positive, crisp Logan Clutch engagement guarantees cycle time repeatability.

- Simplifies clutch maintenance - No disc pack adjustment or slippage.

- Quick-stop, power-applied brake - Prevents machine coasting and provides a safer work environment.

- Low-speed clutch design reduces idle time. Machine operates more consistently.

Savings

- Increase productivity from 10-20%.

- Tools can be positioned closer to the work piece due to repeatable high and low-speed clutch engagement.

- Better machine utilization - More productivity from existing machines, operators and floor space

Additional Benefits

- Self-adjusting disc pack simplifies clutch maintenance

-

Eliminates, linkages, lever arms, yokes, pins, etc.

-

More than twice the torque to move your stock reel, and accurate braking optimizes your bar loader investment

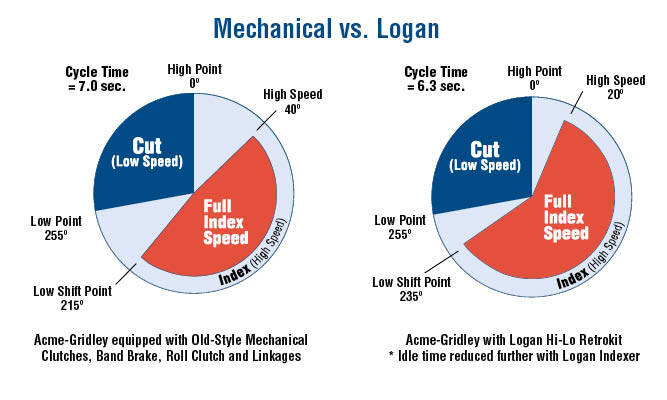

Index Comparison Mechanical Vs. Logan

BSA equipped with Old-Style Mechanical Clutches, Band Brake, Roll Clutch and Linkages

BSA with Logan Hi-Lo Retrokit

* Idle time reduced further with Logan Indexer

Justification Worksheet for your BSA

|

Production time = 16 Hours/Day (70% Efficiency or Run Time) |

|||

|---|---|---|---|

|

Acme-Gridley 1-1/4 RA-6 |

Cycle Time With Mechanical Only |

Cycle time with Logan Retrokit |

% Increase with |

|

Cycle Time (#seconds per part) |

7.00 |

6.30 |

10.0% |

|

Parts per minute (x0.7) |

6.00 |

6.67 |

0.67 |

|

parts per hour |

360.00 |

400.00 |

40.00 |

|

Parts per shift (8 hrs.x0.7) |

2,880.00 |

3,200.00 |

320.00 |

|

Parts per day (2 shifts) |

5,760.00 |

6,400.00 |

640.00 |

|

Parts per week (5 days) |

28,800.00 |

32,000.00 |

3,200.00 |

|

Parts per year (50 weeks) |

1,440,000.00 |

1,600,000.00 |

160,000.00 |

|

Revenue @ 0.15 per part |

$216,000.00 |

240,000.00 |

$24,000.00 |

- Additional parts produced per year - with Retrokit® 160,000

- Total added revenue to companies top line, utilizing existing machine, operator and floor space $24,000.00

Above calculation based on 10% increase in productivity - Varies by machine vintage

Logan Hi-Lo Retrokits For Your Early and Late-Model BSA!

Each Logan Electrical, Mechanical, Pneumatic and Accessory kit is designed to save you time and money during installation. Kits are furnished with detailed mechanical, electrical and pneumatic schematics.

Simple to Install

-

Easily retrofit older machines.

-

Field installation service is also available.

-

Simplifies addition of stock depletion, broken-tool and short-part detectors.

Hi-Lo Retrokit Control Options

1. Standard Cams and Limit Switches

Provides Conventional Cam and limit Switch operation2. CS 2001XT16 Microprocessor Control

- Easy to read 2-line screen Displays cycle time, parts count, machine position in degrees

- Machine Lockup detection

- Low-speed shift points in degrees

- Thread Check - detects tap failure and shuts down your machine before index

- 15 programmable tool counters

- Eliminates auxiliary cams and limit switches

- Stock Load positioning - reduce stock-up by 50%

- Full pre-wired push-button control station

- Eliminates relay logic

- 35 Programmable Tool Counters

- Air coolant, lube pressure monitor capability

Contact Our Sales Team

Our Sales Engineers can help you find the exact product or service you need to succeed.