Euroturn

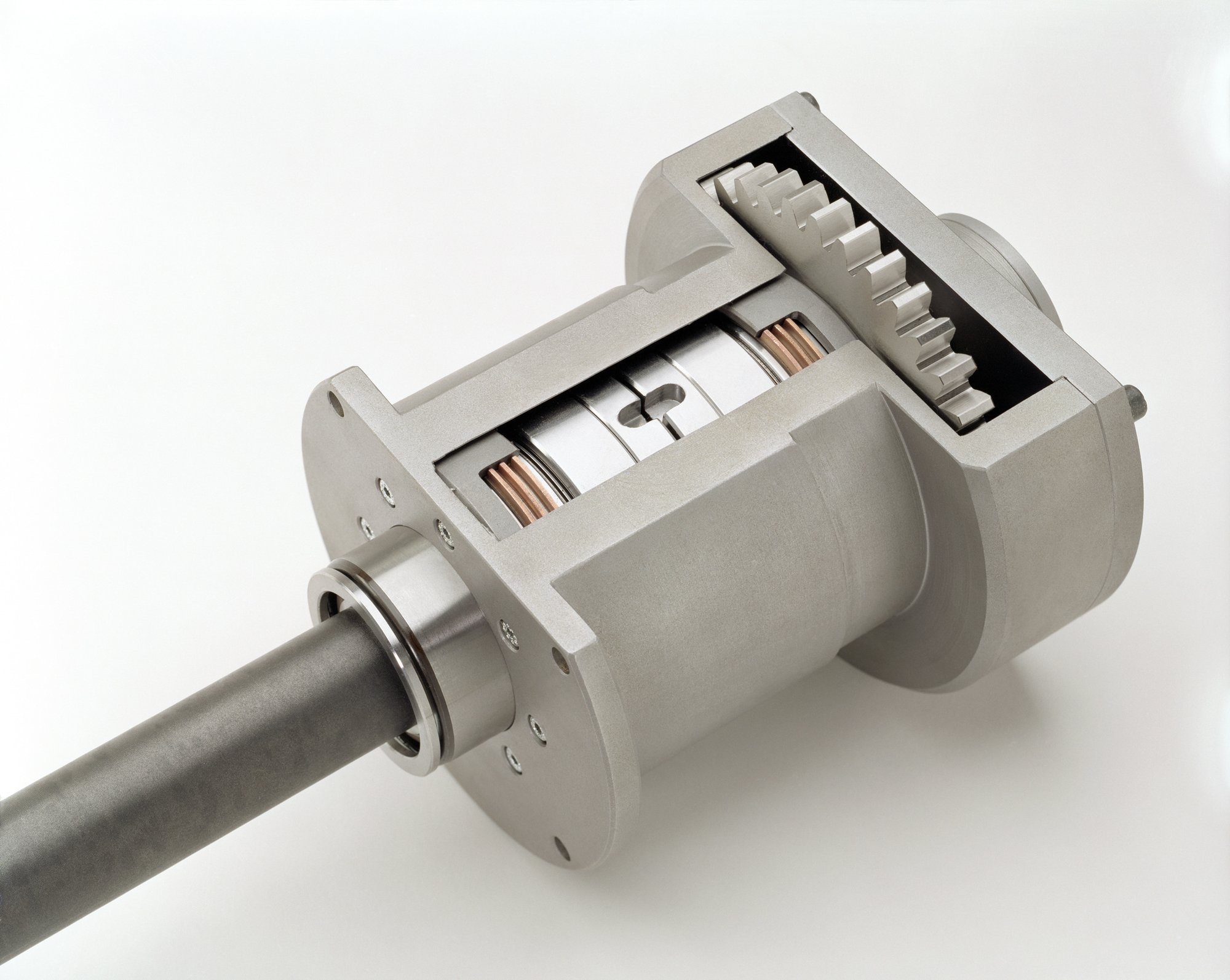

Increase Productivity, Quality, and Tap Life with Logan Hi-Capacity Air Threading Clutches on your early and late model Euroturns!

Thousands of lost production hours can be attributed each year to electromagnetic threading clutches that are over or under adjusted, or slipping on your Euroturn – forcing you to compromise on part quality and tap life.

Euroturn

Air Threading Euroturn

Now you can achieve state-of-the art tapping repeatability, thread quality and tap life on your Euroturn. Our self-adjusting Air Threading Clutches outperform your existing electromagnetic threading clutch in engagement and disengagement, torque and RPM capabilities.

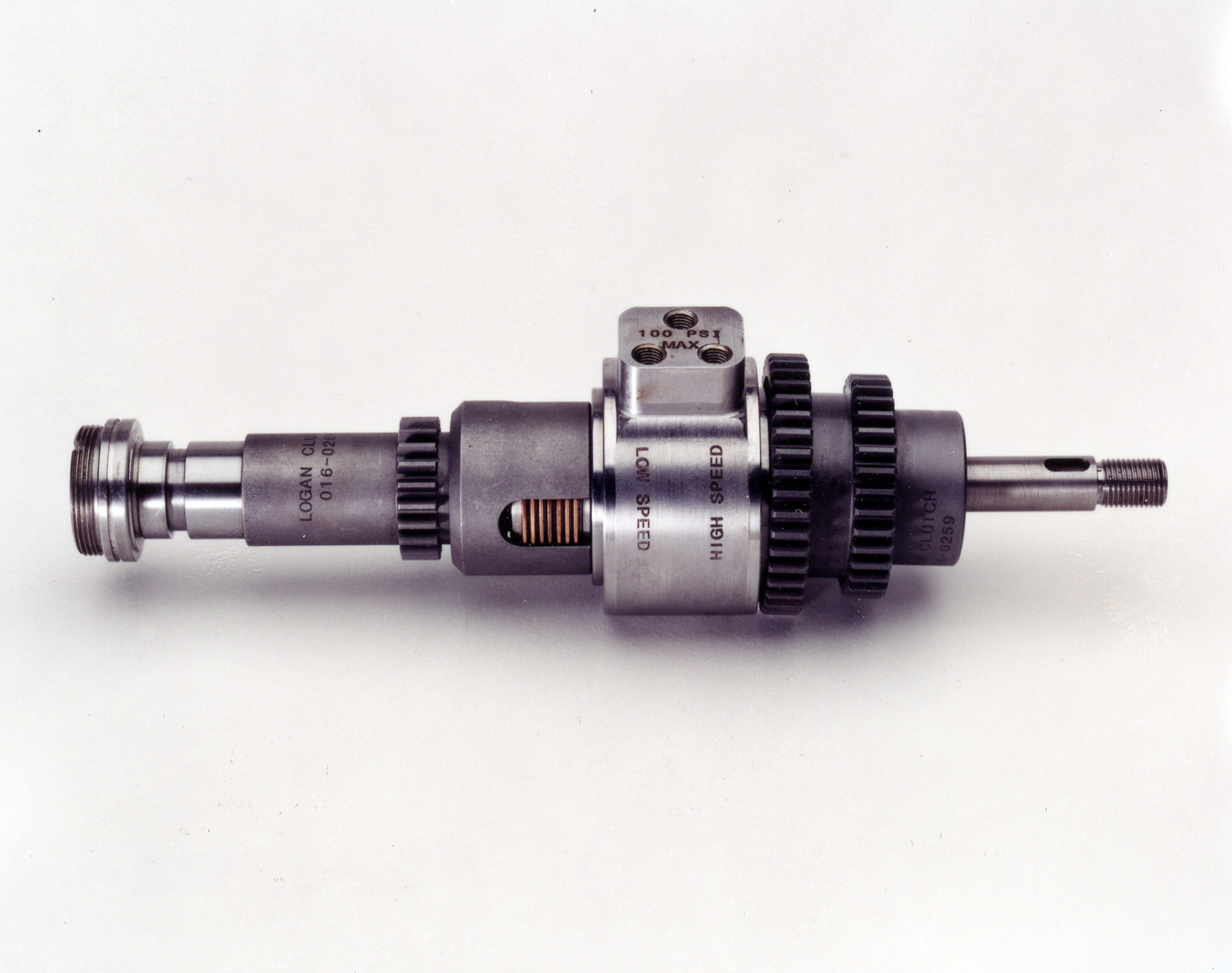

Logan Pick-off Drives for Euroturn Screw Machines

For many years, electromagnetic brakes have been utilized to stop Euroturn pick-off drive spindles, just prior to the pick-off collet opening. Over time, users have discovered that the electromagnetic clutch does not have the braking torque capability to completely stop the Air-Pick-off spindle, thereby ejecting parts that are still rotating in the tool zone 13 causing nicks, marks, lost parts, and machine cross slide jam-ups!