Davenport

Davenport

Logan Air Threading for Davenport

The Logan Clutch is fast acting, providing consistent reliable tap depths for small and large diameter taps, from aluminum and brass to stainless steel. Repeatability within an 1/8th of a turn is the rule, not the exception. Since directional speed changes are smooth, the load on the tap is uniform, prolonging the life of the tap. Fewer tool changes are necessary, shaving valuable hours from a big job.

Logan vs. Servo

Cycle time on a conventional Model B can vary 3-4 tenths of a second or more due to mechanical clutches, linkages, levers, and band brakes that are out of adjustment. For example, if cycle time on a job layout is 2.0 seconds, you may be losing 10% or more in productivity, or almost 200 parts per hour - with only a 2 tenths variation in cycle time! Logan Hi-Lo Retrokits and controls eliminate these challenges - helping you realize significant productivity gains - utilizing the same operator, machine and floor space.

LoganNet Wifi for Davenport

Logan Clutch controls on the screw machines have their RS485 network com lines connected to WiFi Server Modules that allow communications with the customer's WiFi access point in the plant.

Logan Hi-Lo Retrokit™ for Davenport

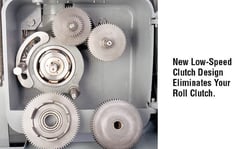

This variation occurs due to an improperly over or under-adjusted mechanical high-speed clutch, starter clutch, or band brake. For example, if your cycle time on a job layout is planned at 2.0 seconds, you are more than likely losing 10% or more in productivity, or almost 200 parts per hour - with only 2-tenths variation in cycle time! Logan can guarantee cycle time repeatability over millions of parts, all without ever stopping the machine to mechanically adjusting a clutch or band brake. Even better, if your layout completes the machining cycle in less than 50 hundredths, your set-up personnel can adjust the high and low shift points in degrees or hundredths to speed up the job.

CS 2001XTP Davenport

The CS 2001XTP is specifically designed to bring new machine technology to your existing fleet of screw machines. With features such as Tool Counters, Thread Check, Machine LockUp Detection, Stock Load and more, the XT offers screw machine users more flexibility during set-ups, and increases overall machine productivity.