Support Door Interlock for Screw Machine

Logan CS2001 Controls Support Door Interlock & Start Interrupt Switches.jpg?width=334&height=507&name=door_switchjpg-1424403512%20(1).jpg)

OSHA rulings and regulations are requiring screw machine users to upgrade their machines with door interlock switches. The purpose is to ensure that the machine cannot be started when a door is open.

The CS2001 control from Logan Clutch is a solution that has passed OSHA scrutiny in hundreds of machines. It works with the dedicated inputs of the CS2001 control and the three levels of programming security in the software. One security level is Set-up mode. Access to Set-up mode is controlled and secure. When a machine door is open it can only be jogged while in Set-up mode only. This enables CS2001 users to work in the tool zone, jog the machine and know that the machine cannot be started.

Simple Integration

The Logan Clutch CS2001 is a proven solution. There are multiple machine rebuild partners and field service technicians with the experience to install these systems for customers. The CS2001 provides benefits beyond OSHA compliance. The features of the CS2001 enable customers to improve the productivity and the reliability of the machines and they are supported by complete documentation and manuals for ongoing support. A compliance alternative that provides a payback is unique alternative to big problem for many screw machine shops.

Above: Logan CS2001 Controls Support Door Interlock and Start Interrupt Switch (Square D#9007C54B2)

CS2001 Door Start Interrupt Switch Inputs: How They Work

The CS2001 Microprocessor Control has two pairs of inputs for two Door Interlock Switches. Each pair of is designed for one normally opened switch contact and one normally closed switch contact. The control senses both inputs together and has an override/defeat checking feature to monitor door input functionality.

Logan Clutch CS2001 Kit Hardware

CS2001 Machine Condition / Error Message / HMI Display

The CS2001 Microprocessor Control has an 8 line LED display. The display provides a descriptive message of any alarm or error message that occurs or causes the machine to stop.

CS2001 features that generate payback (Partial List)

Stock Load Position Selector Switch: automatically stops the machine in the correct position for material loading.

Thread Check Failure System: Shuts the machine down if a part is not tapped.

Short Part & Broken Tool Detectors easily integrate with the CS2001 control.

Stock Depletion Detector Inputs: receives intelligent input from your sensor and shuts down the machine when the bar stock becomes too short to feed out to length.

Machine Lock-up Detection: Detects main drum shaft rotation and shuts down the machine if a lock-up condition occurs, minimizing clutch damage and other potential problems.

Cycle Time Display: Displays the machine cycle time in seconds. Useful in detecting machine problems. Cycle time variation may indicate clutch slippage.

CS2001 Machine Condition / Error Message / HMI Display

The CS2001 Microprocessor Control has an 8 line LED display. The display provides a descriptive message of any alarm or error message that occurs or causes the machine to stop.

Typical CS 2001XTP Hardware

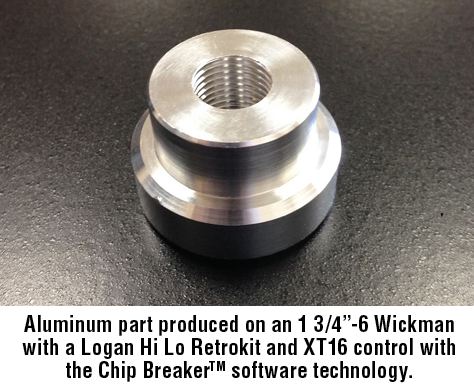

Ideal for Acmes, New Britains, Davenports and Wickmans

CS2001 XT16 features that generate payback (partial list)

Stock Load Position Selector Switch: Automatically stops the machine in the correct position for material loading

Thread Check Failure System: Shuts the machine down if a part is not tapped.

Tool Change Counters: Shuts down the machine at the designated tool service time; minimizing tool changes and maximizing quality finishes and threads. There are 15 available.

Stock Depletion Detector Inputs: Receives intelligent input from your sensor and shuts down the machine when the bar stock becomes too short to feed out to length.

Machine Lock-up Detection: Detects main drum shaft rotation and shuts down the machine if a lock-up condition occurs, minimizing clutch damage and other potential problems.

Reduce Setup Time: Program high and low speed points, providing the operator flexibility during setup and avoid having to mechanically re-time the high speed and brake cams.

Cycle Time Display: Displays the machine cycle time in seconds. Useful in detecting machine problems. Cycle time variation may indicate clutch slippage.

Contact Our Sales Team

Our Sales Engineers can help you find the exact product or service you need to succeed.