Chip Breaker

Logan XT16 Chip Breaker Software

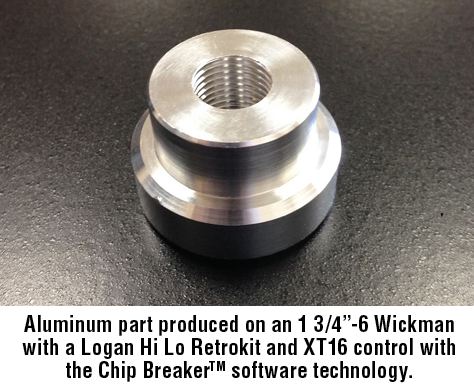

Logan Clutch now offers Chip Breaker™ technology on its line of CS2001 and CS2001 XT16 Microprocessor Controls. Chip Breaker technology enables Acme, New Britain and Davenport users to minimiz or eliminate nesting of metal stringers that occur in the feed cycle (when making aluminum and/or steel parts). This feature minimizes the need for operators to tend to or shut down the machine to clear chips.

In addition to the Chip Breaker software settings, other factors must be considered and potentially modified. These are the feed rate and the tooling. Industry feedback is that it should take no more than 2-3 revolutions of the spindle to break the chip, whether you are using a chip breaker cam or our software. The feed rate must also be considered and keep in mind the back pressure of the feed, which varies during the cycle.

Note that a hard coded timer is used in the logic that ensures the machine does not dwell for more than 1/2 second. This is done to avoid a machine lockup condition by using these features.

Chip Breaker™ technology is available as an option on new and existing CS2001 XT16 controls and is ideal for users of solid aluminum (and some steel) material.

Contact Logan today for more details.

Typical CS 2001XTP Hardware

Ideal for Acmes, New Britains, Davenports and Wickmans

CS2001 XT16 features that generate payback (partial list)

Stock Load Position Selector Switch: Automatically stops the machine in the correct position for material loading

Thread Check Failure System: Shuts the machine down if a part is not tapped.

Tool Change Counters: Shuts down the machine at the designated tool service time; minimizing tool changes and maximizing quality finishes and threads. There are 15 available.

Stock Depletion Detector Inputs: Receives intelligent input from your sensor and shuts down the machine when the bar stock becomes too short to feed out to length.

Machine Lock-up Detection: Detects main drum shaft rotation and shuts down the machine if a lock-up condition occurs, minimizing clutch damage and other potential problems.

Reduce Setup Time: Program high and low speed points, providing the operator flexibility during setup and avoid having to mechanically re-time the high speed and brake cams.

Cycle Time Display: Displays the machine cycle time in seconds. Useful in detecting machine problems. Cycle time variation may indicate clutch slippage.

Contact Our Sales Team

Our Sales Engineers can help you find the exact product or service you need to succeed.