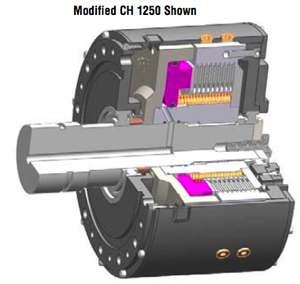

CH Technical Data for Wet or Dry Operation

Modified Standards Available

Higher torque ranges, actuation pressures, and stronger release springs are available to meet customer’s specific design requirements. Contact Logan for more details.

| Duty | SF |

|---|---|

| Small Inertia Low Cycle Rate Non-pulsating Load | 1.3 to 1.7 |

| Large Inertia Low Cycle Rate Non-pulsating Load | 1.7 to 2.2 |

| Small Inertia High Cycle Rate Pulsating Load | 2.2 to 3.2 |

* Data shown is subject to change. Please consult factory for current dimensional data.

Selection Procedures

I Calculate the torque requirement for the application using one of the following formula

Torque (Lb./In.) = HP* 63025/RPM

or

Tc (Nm.) = HP* 9550/RPM

II Identify the service factor which best identifies your application from the suggested service factor table.

III Adjust the torque requirement using the selected service factor.

Gross Torque Capacity (T) / Safety Factor (SF)

T= Tc x SF or T=Tb x SF

IV. Determine if the model will:

1) Accommodate the shaft and key

2) Operate at the required speed

3) Fit within the available space

V. Determine the Drive Ring Mounting

Vl. Complete the Application Fact Sheet

provided in this brochure or complete online

at www.loganclutch.com. Call, e-mail, or

Fax your application and place your order.

HP = Horsepower

RPM = Clutch or Brake shaft speed

WR2 = Total inertia to be stopped (Ib.ft.2)

T = Required Torque (Lb./ Ft., Nm, Lb./in)

Tc = Clutch Torque (Lb./ Ft., Nm, Lb./in)

Tb = Brake Torque (Lb./ Ft., Nm, Lb./in)

t = Time to stop (seconds)

SF = Service Factor

Torque & Horsepower Formulas

HP = T(Lb./Ft.)*RPM /5250

Torque (Lb./Ft.) = HP*5250/RPM

HP = T(Lb./Ft.)* RPM / 63025

Torque (Lb./In.) = HP * 63025 / RPM

HP = T(Nm..) x RPM /9950

Torque (Nm.) = HP*9950/RPM

|

Torque Conversion Calculators |

Multiplier |

Contact Our Sales Team

Our Sales Engineers can help you find the exact product or service you need to succeed.