Air Threading Wickman

Air Threading Wickman

Logan Air Threading Clutches for all Wickman Screw Machine sizes

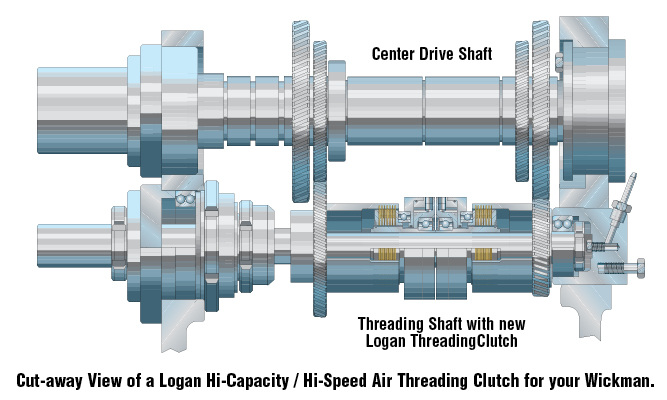

Logan Air Threading Clutches employ the original drive cups or clutch gears to drive the threading spindle.

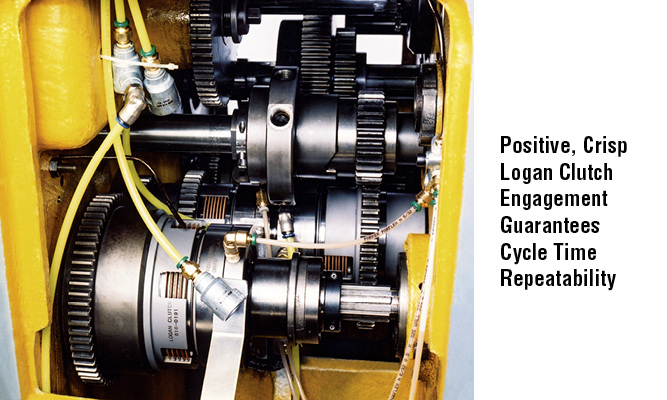

Change of speed is accomplished by a limit switch and a solenoid activated, directional control valve. At the prescribed depth, the limit switch is tripped by the threading slide shaft, shifting the Low-speed clutch to the High-speed clutch, allowing the tap to back out. Slow speed for tapping; Fast speed to back out.

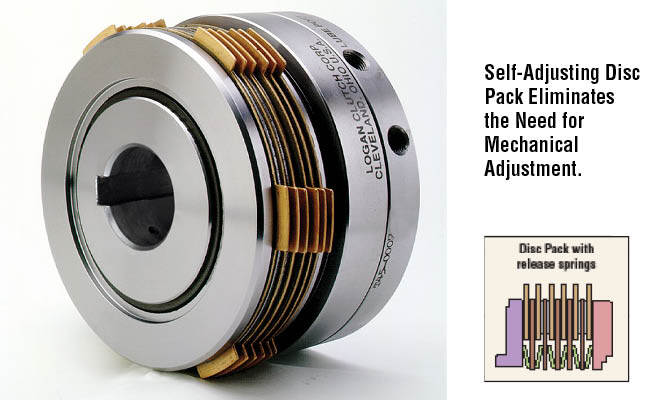

Self Adjusting Disc Pack

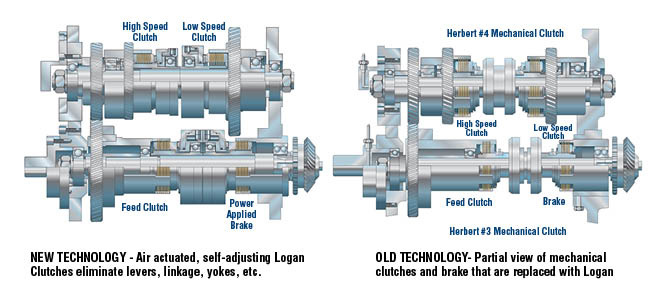

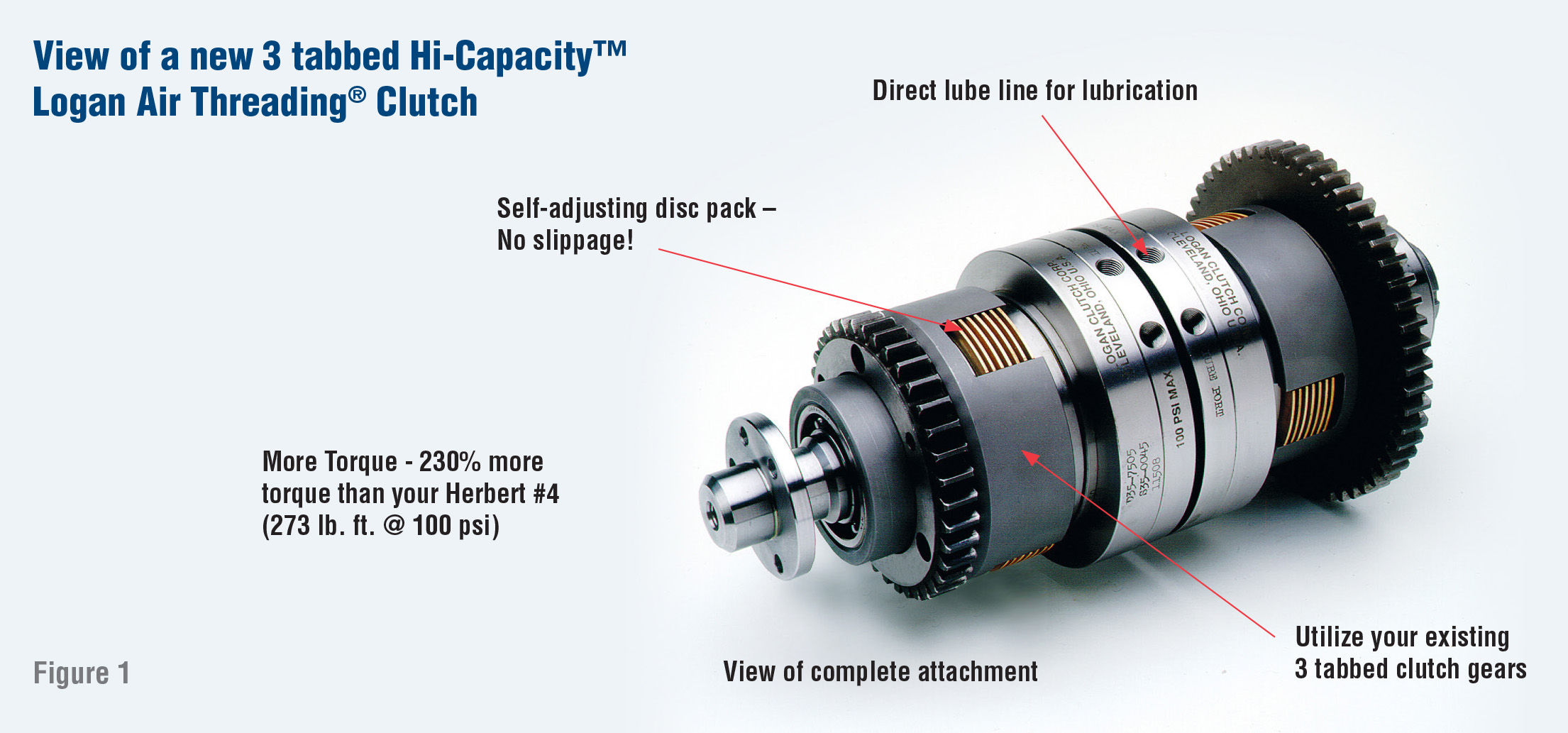

Today, a new solution exists to engage and disengage threading operations that offers greater reliability, self-adjustment, consistent performance, more torque, and almost maintenance free operation (figure 1).

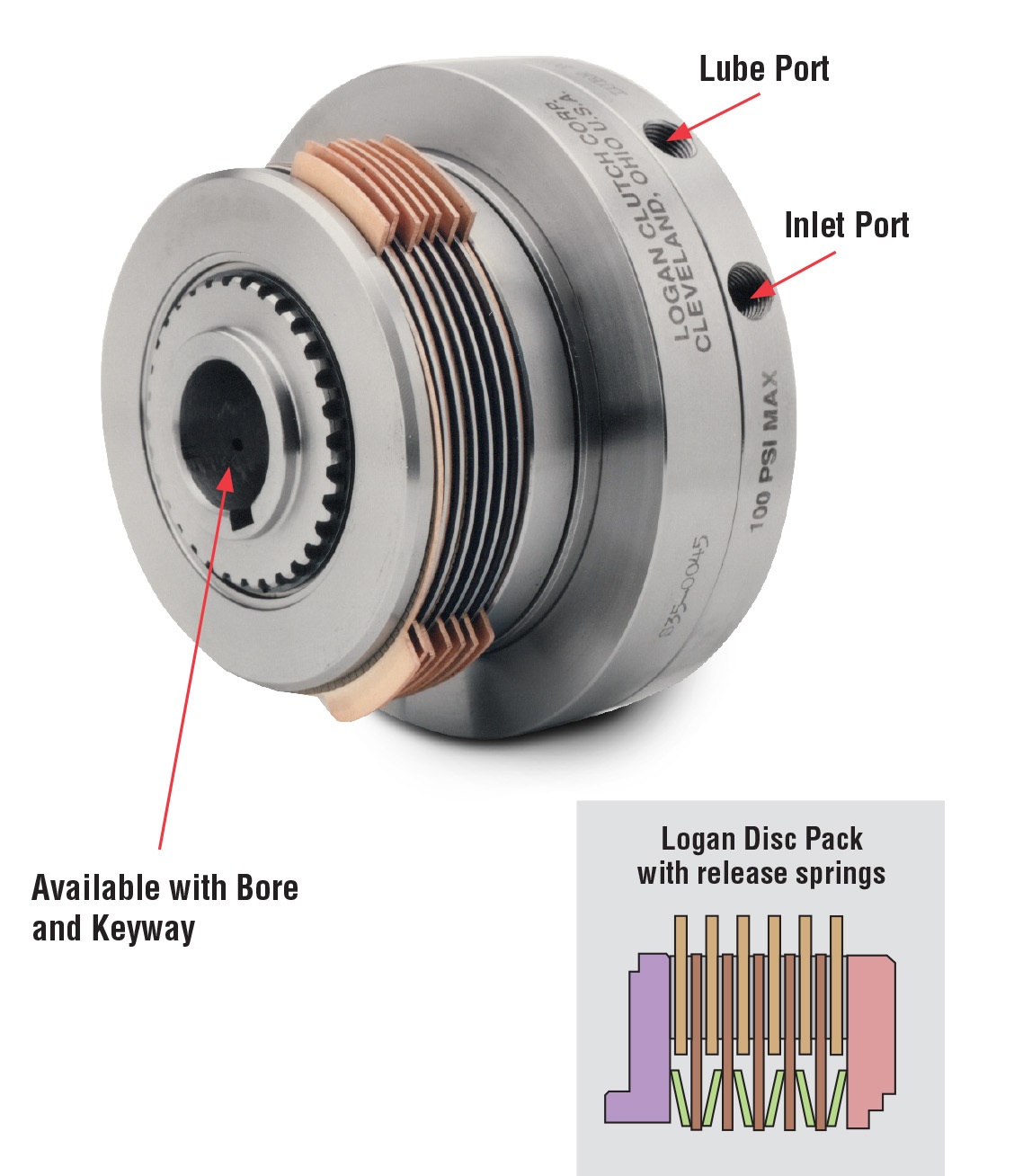

Logan Clutches are simple to maintain because they compensate for disc wear automatically. And unlike mechanical linkages, air pressure provides consistent force to provide positive transfer of torque, and extremely accurate tap depths.

Maintenance Free Operation - Increased Productivity

Maintenance-free operation means more uptime, because you’ll no longer have to repeatedly shut down the machine to make adjustments for disc pack wear. And, faster acting, more reliable clutches mean shorter cycle times. All of this leads to increased productivity, that’s why Logan Clutches are featured as Original Equipment on all National Acme, New Britain, and Davenport Screw Machines. Retrofitting your Wickman Automatic with a Logan Air Threading® Clutch will save you thousands of dollars by lowering operating costs.

New 3 Tab Design - Simple To Install

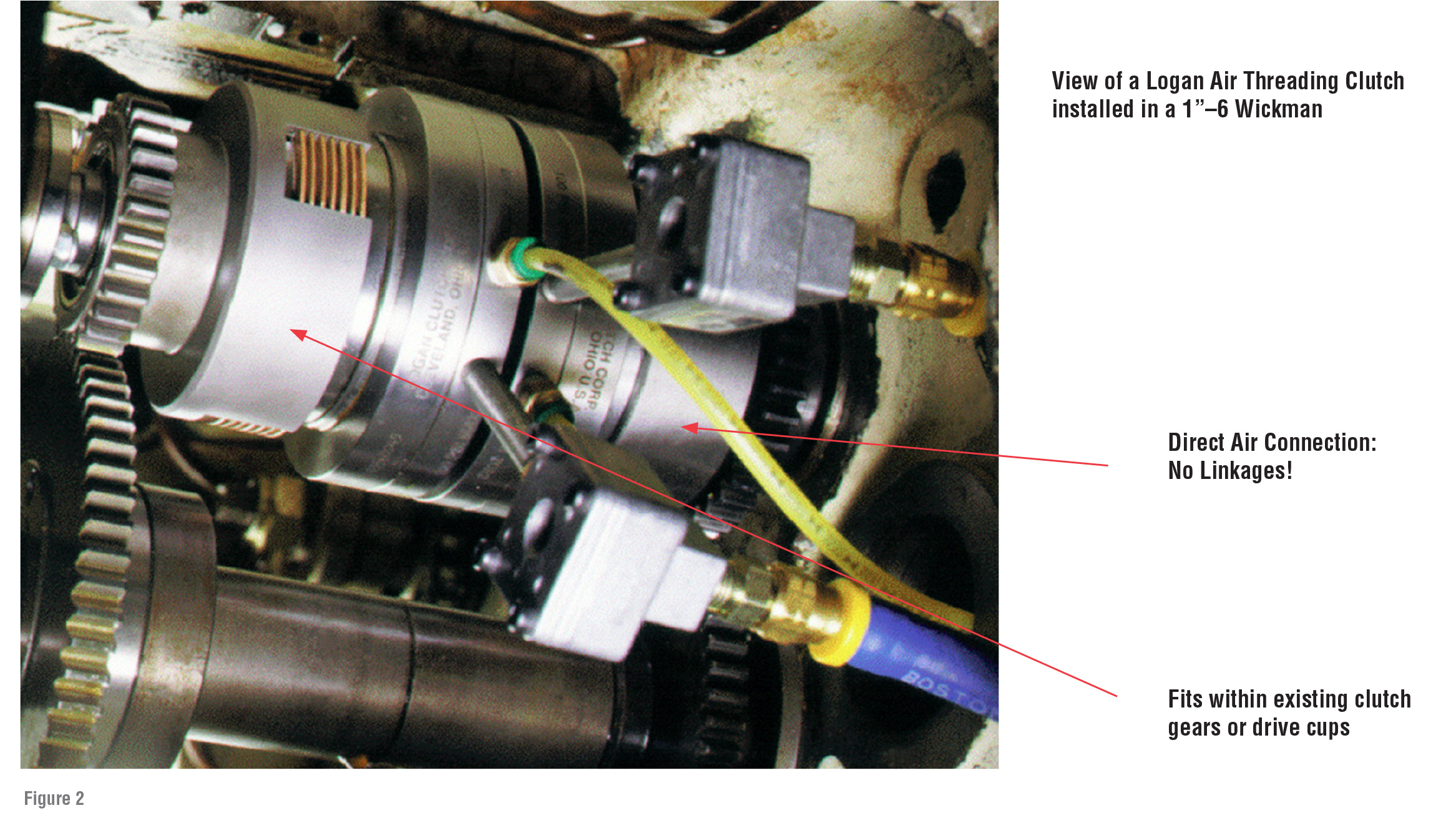

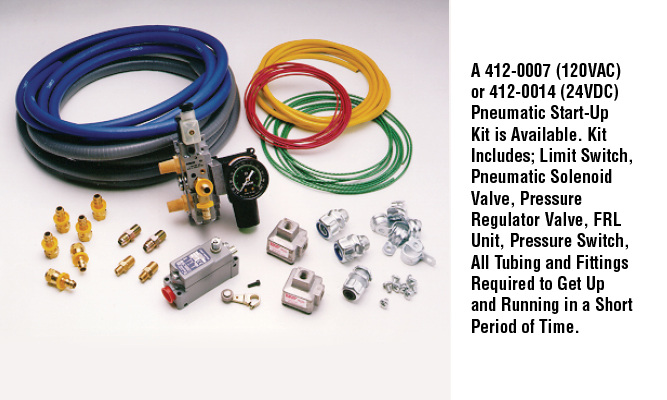

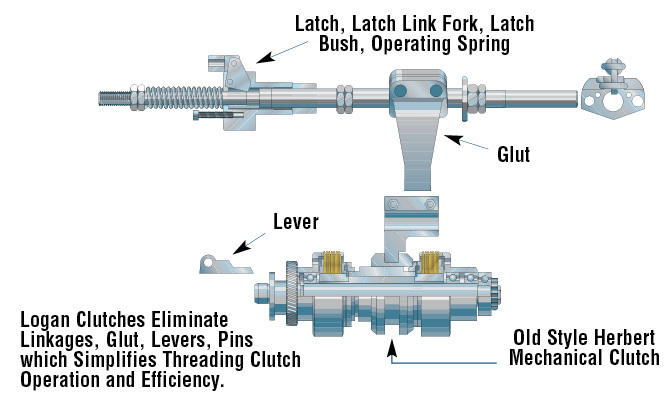

Simply replace your mechanical Herbert Multi-Grip Clutch with new, dimensionally interchangeable Logan Air Threading Clutches. Logan Clutches are designed to fit within your existing 3 slot clutch gears, or drive cups (See figure 2). In addition to Air Threading Clutches, Logan offers Electro-Pneumatic Start-Up Kits, and Accessory Packages which come complete with all of the valves, hose, and limit switches, necessary to make the switch from mechanical to Logan quick and easy.

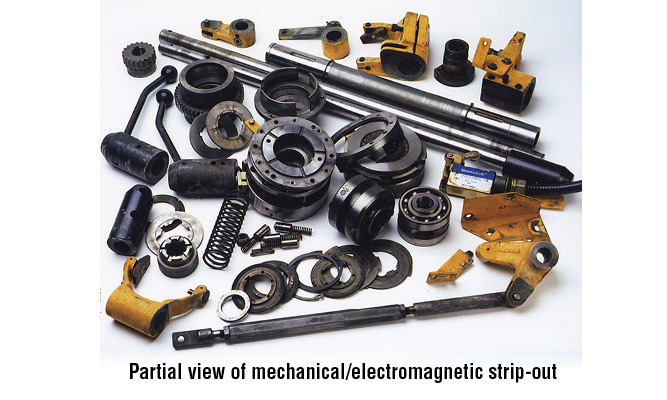

Air Actuation - Logan Is More Reliable Than Electromagnetic Clutches

Logan Air Threading clutches operate at a consistent rate based on air pressure. Electromagnetic units maintain residual magnetism, which hampers engagement and disengagement, thus increasing the idle time between speeds. Using shop air also eliminates the magnetic attraction of foreign particles to the bearing and disc pack which cause electromagnetic clutches to become sluggish and fail prematurely. Plus Logan clutches transmit much more torque within a smaller envelope - which is ideal for tapping modern-age materials.

Logan Air Threading® Clutches for All Wickman Screw Machine sizes

How They Work

Logan Air Threading™ Clutches employ the original drive cups or clutch gears to drive the threading spindle.

Change of speed is accomplished by a limit switch and a solenoid activated, directional control valve. At the prescribed depth, the limit switch is tripped by the threading slide shaft, shifting the Low speed clutch to the High speed clutch, allowing the tap to back out. Slow speed for tapping; Fast speed to back out.

Logan Clutches:

High Torque / Small Envelope

Pressurizing the Logan clutch cylinder-piston assembly forces the piston to clamp and lock the friction and steel separator discs. Torque is transmitted through to the drive cup or clutch gear slots. When pressure is removed, release springs separate the separator discs and maintain a running clearance between separator and friction discs. The amount of pressure controls the amount of torque. Logan clutches are self–adjusting. Piston travel increases automatically to accommodate disc wear.

Lubrication

Since Logan Air Threading™ clutches operate at relatively high speeds, a steady flow or spray of oil directed at the disc pack and bearing surfaces is necessary to dissipate the thermal energy generated during operation.

Convenient To Maintain

Logan clutches are self-adjusting.

Piston travel increases automatically to accommodate disc wear.

Logan Clutches do not require linkages, lever arms, adjusting collars, dog levers, spring pins, yokes, clutch sleeves, etc.

At Air Threading® service time, in-stock disc pack, seal kit and bearing repair kits, along with factory installation data sheets, simplify maintenance.

Here’s How To Order

Specify make or model and year of the machine. Provide Part number and brand of clutch that is being replaced.

Confirm bore, keyway, axial length of the clutch. Indicate if you would.

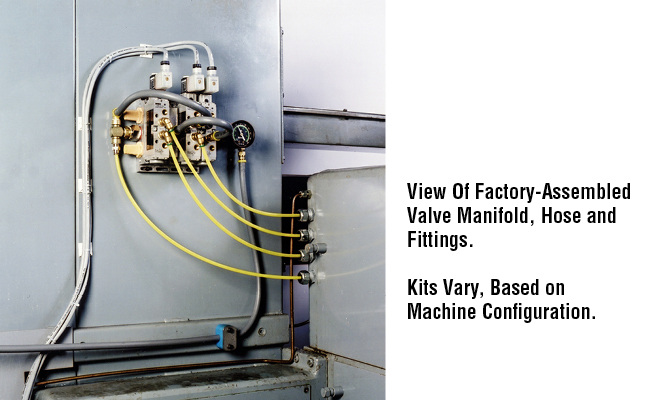

Electrical/ Pneumatic Start-Up Kits

Start-Up Kit Includes Valve Assembly, Pressure Gauge, Pressure Regulator, Limit Switch, Quick Exhaust Valves, Fittings, Bracket, Hose and Schematics.

There is a Logan Air Threading® Clutch for almost every screw machine produced.

Contact Our Sales Team

Our Sales Engineers can help you find the exact product or service you need to succeed.