Air Threading BSA

For Your BSA Gridley

Increase Productivity, Thread Quality, and Tap Life

Year after year, lost production hours are attributed to mechanical threading clutches that are over or under adjusted on your Acme-Gridley screw machine - forcing you to compromise on part quality and tap life.

Now, you can achieve state-of-the-art tapping repeatability, reliability, and quality with Logan Hi-Capacity Air Threading™ Clutches. Engagement and disengagement are so smooth and positive - Tap depth remains consistent over millions of parts.

Also, the load on your tap is uniform, prolonging the life of the tap. Fewer tool changes are necessary, shaving valuable hours from a big job. Logan also provides up to 200% more torque for heavy-duty pipe thread tapping.

Logan Hi-Capacity Air Threading™ Clutches are simple to install and available for almost every Acme ever manufactured.

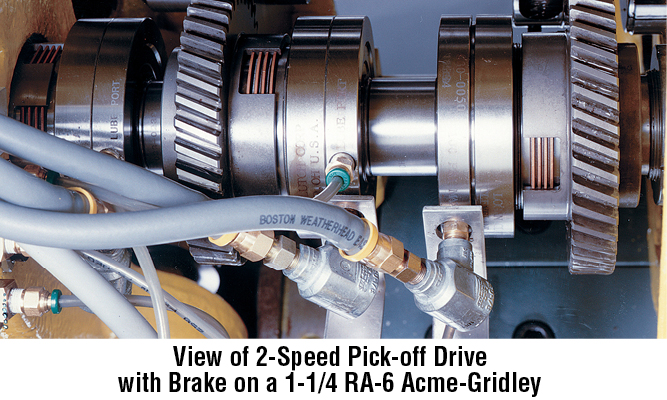

Hi-Lo Retrokit

New Logan Hi-Lo Retrokits for your early and late-model BSA's increase your machines daily and weekly output from 10-20% - leaving you room for additional capacity, productivity and profitability. Positive, fast-acting Logan Clutch engagement enables your Acme to change speeds much faster, and provides a more consistent and accurate cycle time than conventional mechanical clutches.

Contact Our Sales Team

Our Sales Engineers can help you find the exact product or service you need to succeed.