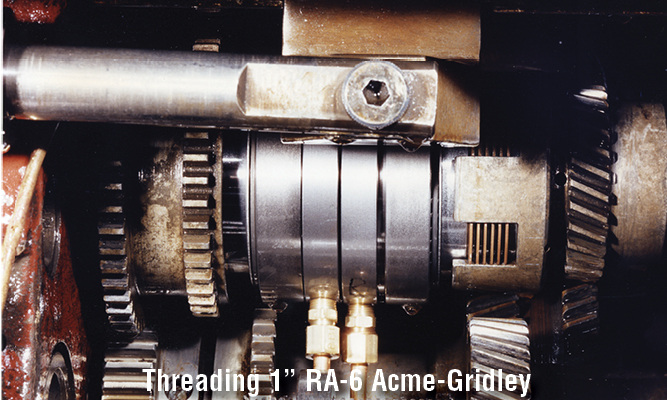

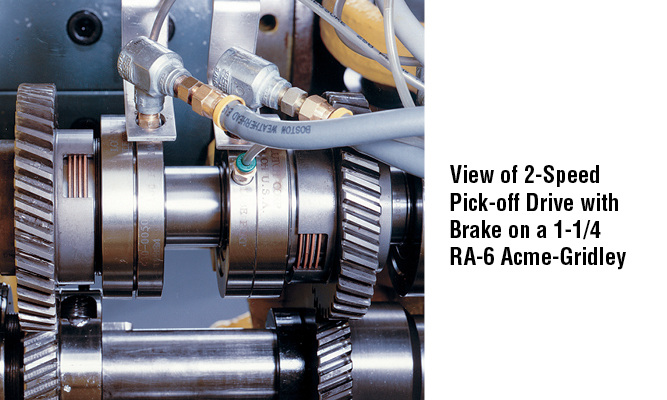

Air Threading Acme-Gridley

Air Threading Acme-Gridley

Increase Productivity, Thread Quality and Tap Life

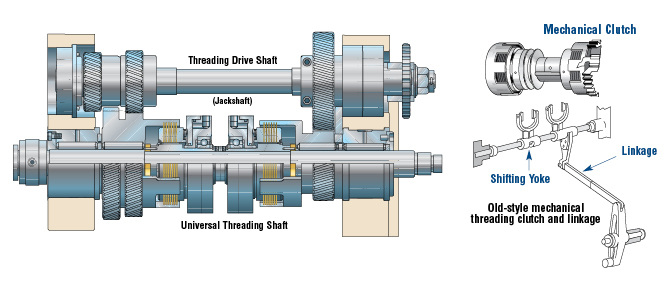

Year after year, lost production hours are attributed to mechanical threading clutches that are over or under-adjusted on your Acme-Gridley screw machine - forcing you to compromise on part quality and tap life.

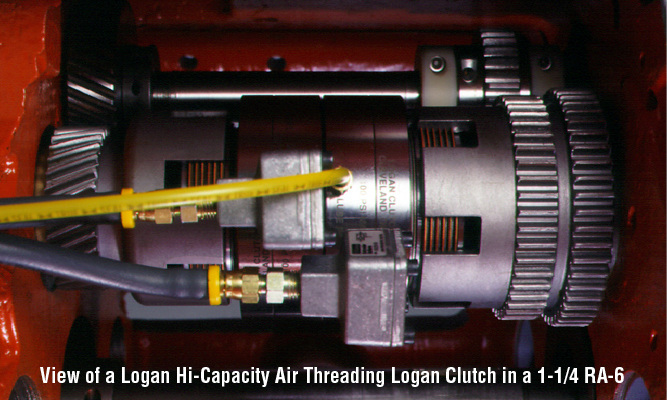

Now, you can achieve state-of-the-art tapping repeatability, reliability, and quality with Logan Hi-Capacity Air Threading® Clutches. Engagement and disengagement are so smooth and positive - Tap depth remains consistent over millions of parts.

Also, the load on your tap is uniform, prolonging the life of the tap. Fewer tool changes are necessary, shaving valuable hours from a big job. Logan also provides up to 200% more torque for heavy-duty pipe thread tapping.

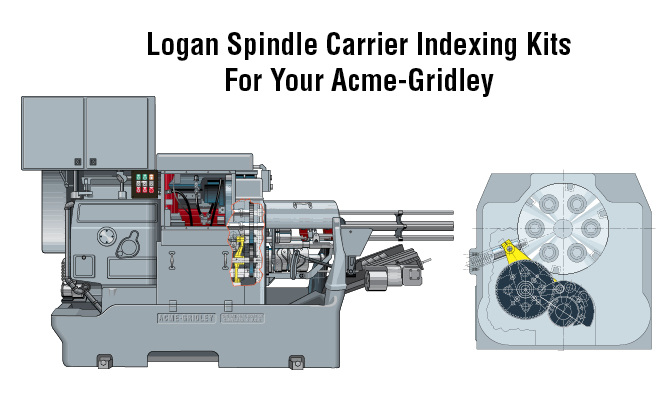

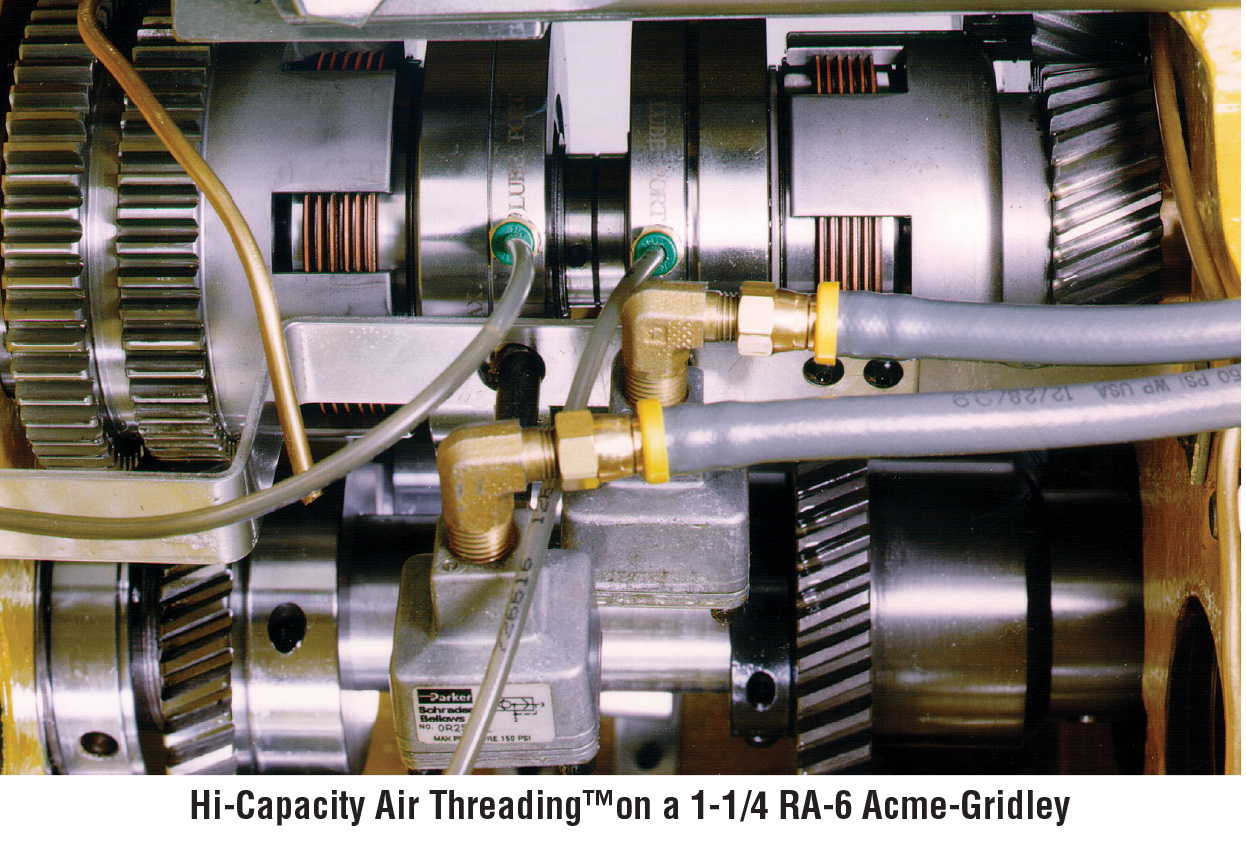

Logan Hi-Capacity AirTM Threading Clutches are simple to install and available for almost every Acme ever manufactured.

Increase Productivity And Quality

- Self-Adjusting Disc Pack - No Slippage.

- Extremely Accurate - Uniform Thread Depth Over Millions of Parts.

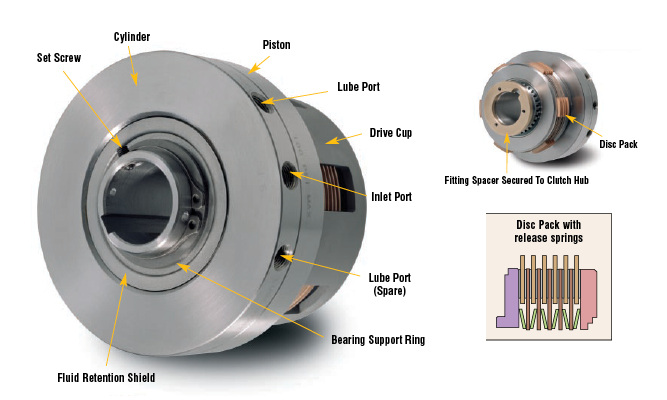

- Large Cylinder - Piston Area For Maximum Torque.

- Up To 200% More Torque Than Mechanical Clutches.

Simple to Install

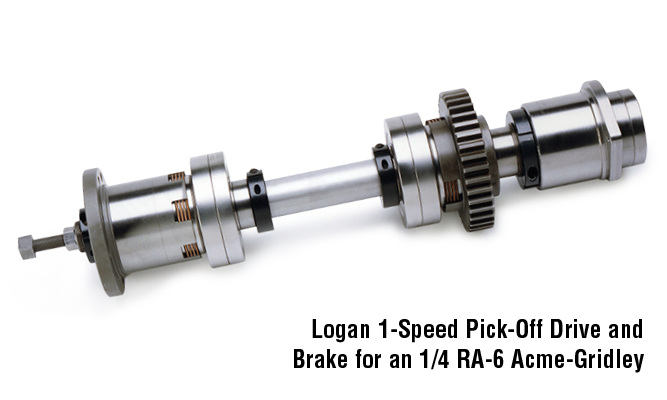

- Most Logan Air Threading Clutches utilize existing clutch drive cups, (clutch gears), spacers and shafts.

Convenient To Maintain

- Increase Tap Life Through Positive Clutch Engagement.

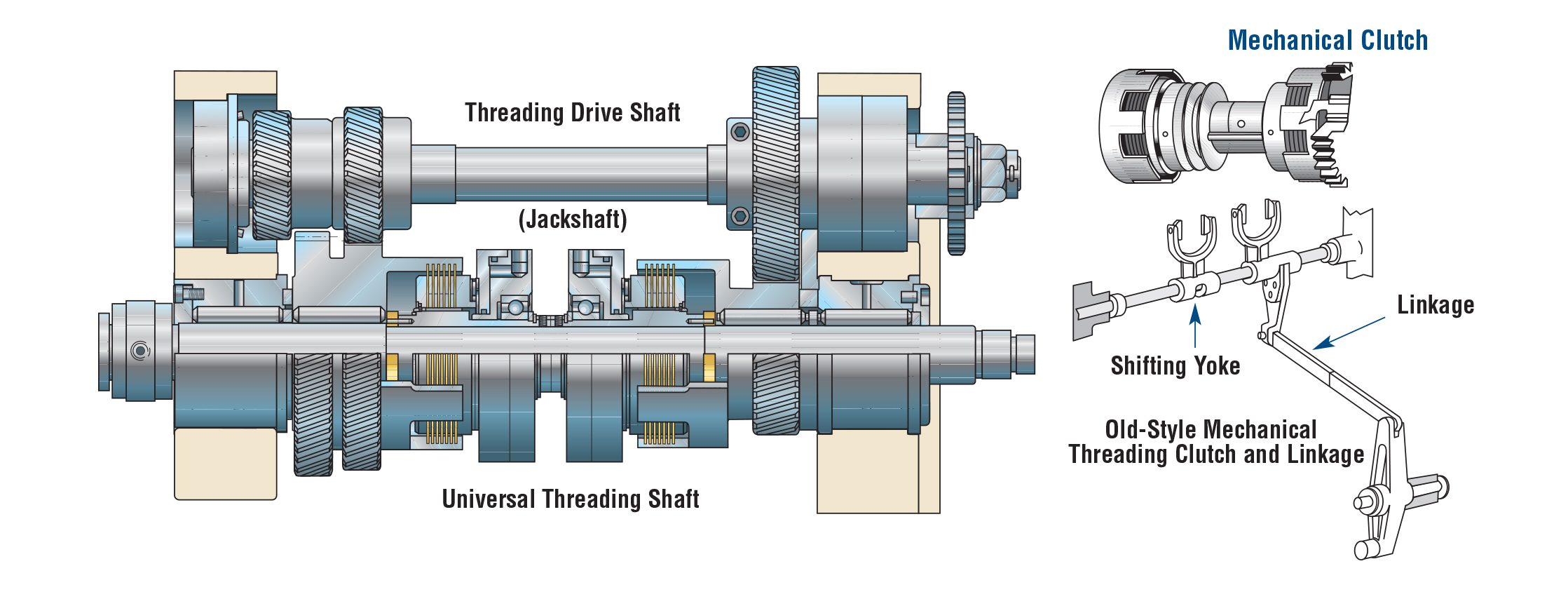

- Eliminates Mechanical Linkages – Lever Arms, Adjusting Collars, Dog Levers, Spring Pins, Yokes, Clutch Sleeves, etc.

- Eliminates Mechanical Clutch Adjustment.

Additional Benefits

- Direct Air Connection – No linkages

- Utilizes existing clutch gears in most cases

- Gain speed and cycle time by running larger tapping jobs on smaller machines

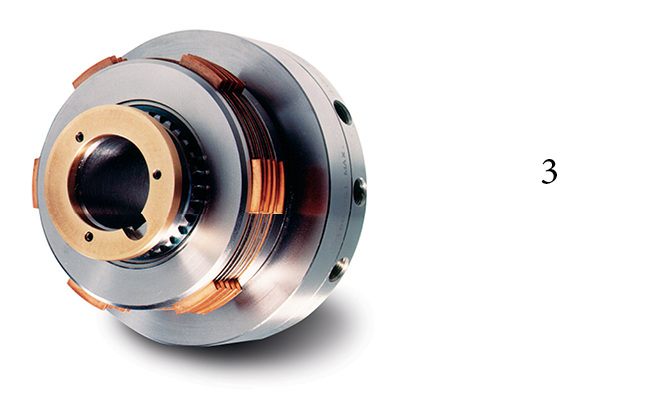

Logan Hi-CapacityTM Air Threading Clutches

Logan Clutches – How They Work

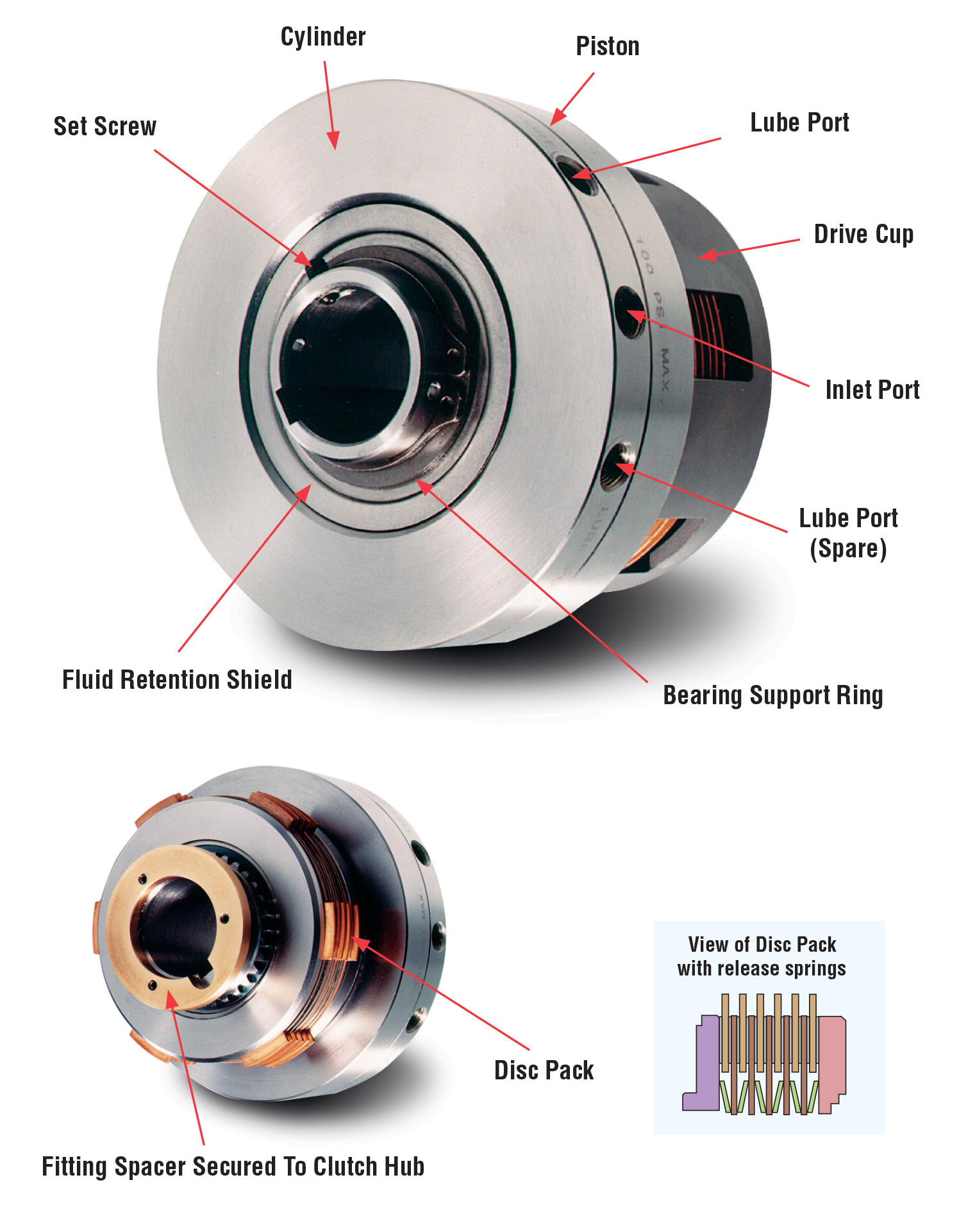

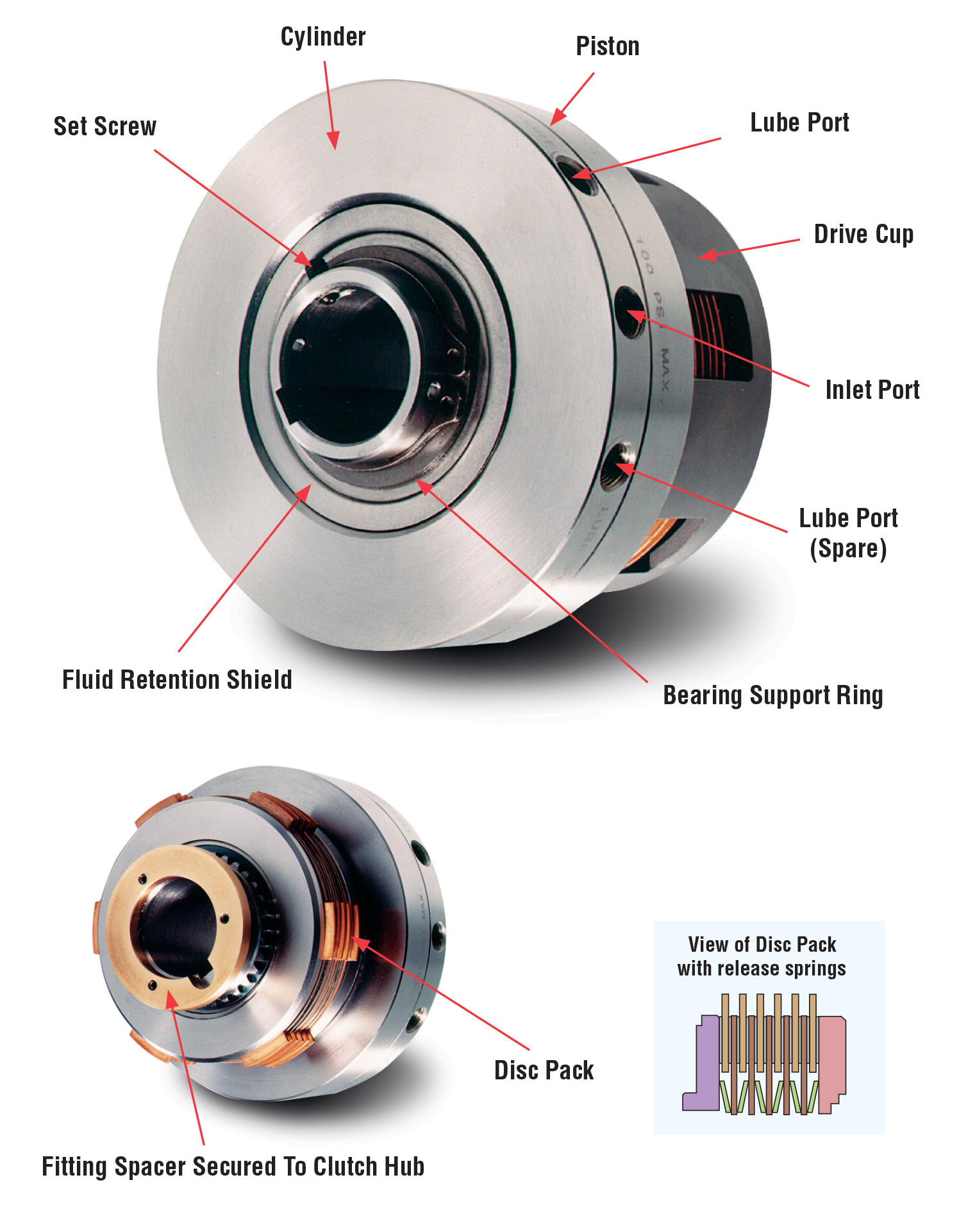

Pressurizing the cylinder forces the piston to clamp and lock the friction and steel separator discs. When pressure is removed, release springs separate the separator discs and maintain a running clearance between separator and friction discs.

The amount of pressure controls the amount of torque.

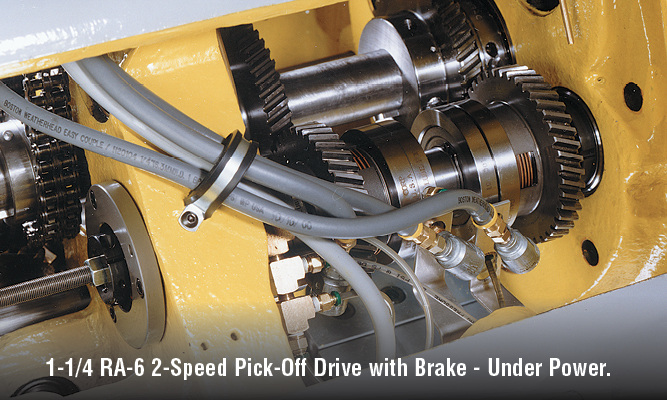

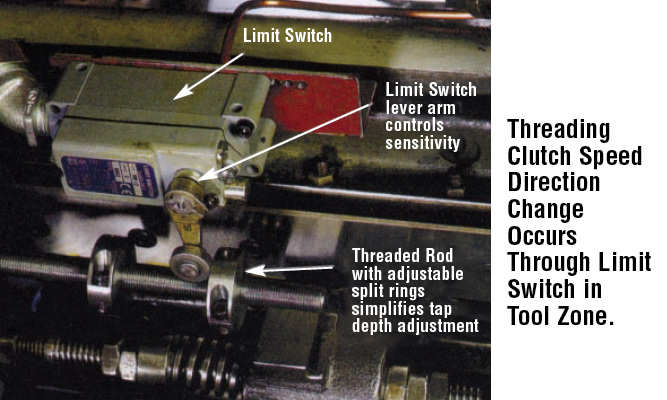

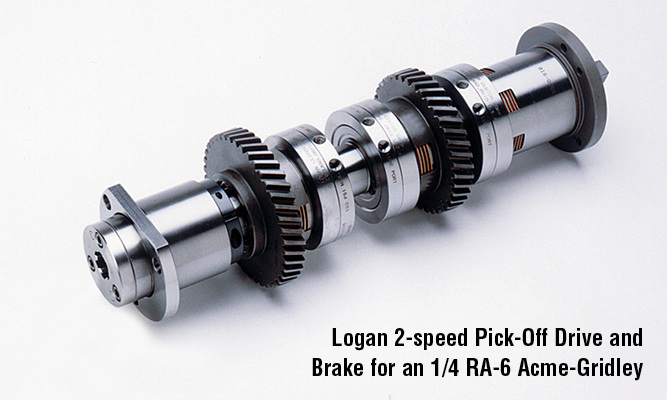

Speed Changes

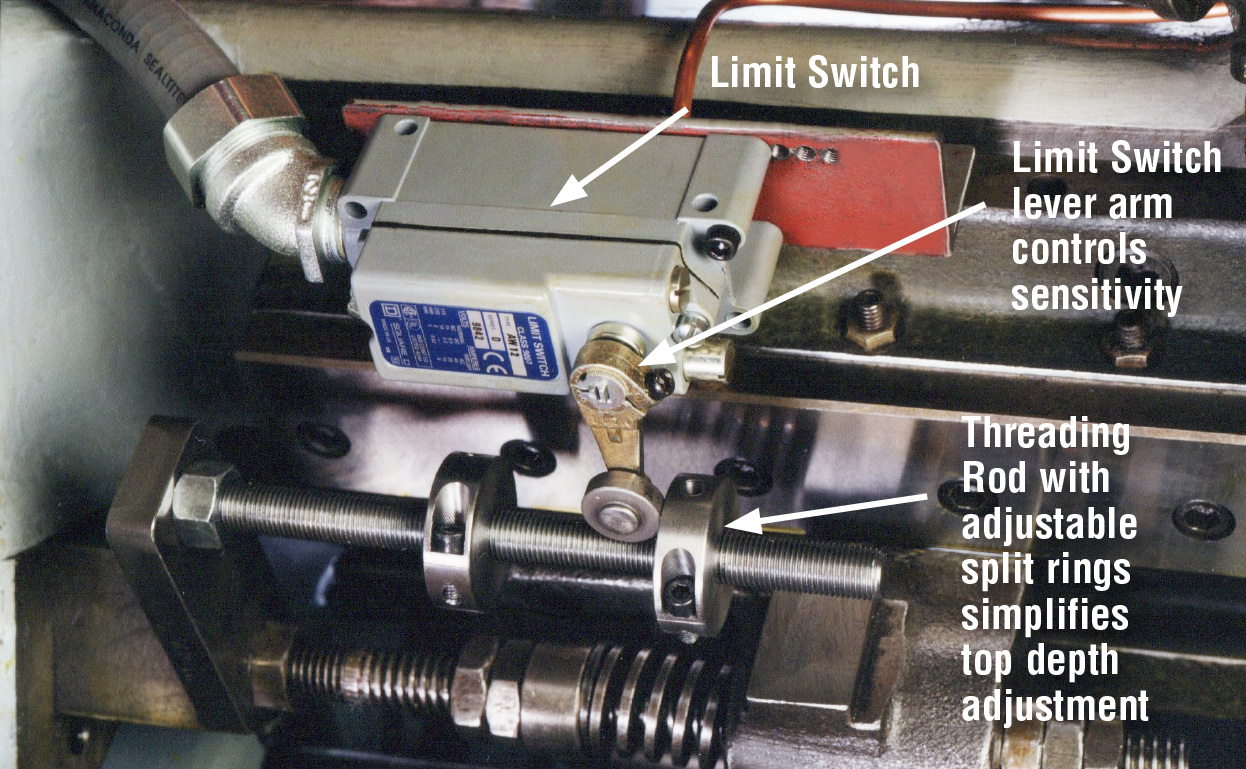

Change of speed in threading applications is accomplished through a limit switch and a solenoid-activated, directional control valve. At the prescribed depth, the limit switch is tripped by the threading slide shaft, signaling the threading clutch to change speeds. Low speed for tapping - Fast speed to back the tap out. (Left hand threading applications require the inverse sequence).

Lubrication

Since Logan Clutches operate at relatively high speeds, a steady metered flow of lubrication is required over the bearing and disc pack surfaces.

Logan Air Threading for your Acme-Gridley

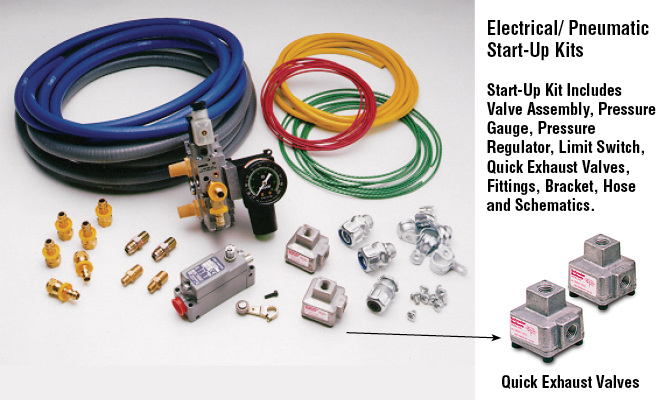

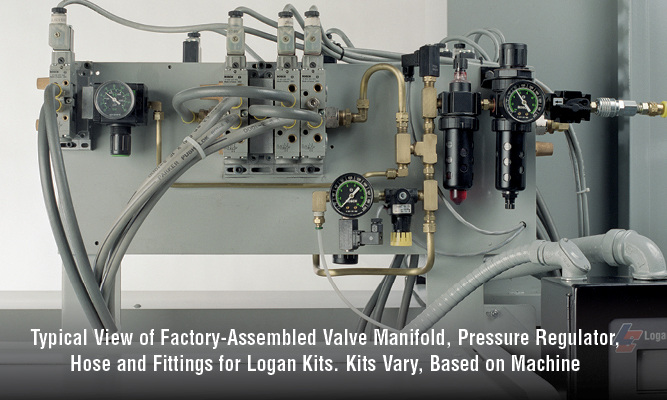

Electrical-Pneumatic Start-Up Kits

Each Logan electrical – pneumatic start-up kit is designed to save you time and money during Installation. Kits are furnished with detailed schematics to simplify Installation.

Simple to Install

- Easily retrofits with all types of early and late-model screw machines.

- Field installation service is also available.

How to Order

- Call Logan and specify machine make and model. Provide part number and brand of clutch being replaced.

- If necessary, confirm bore, keyway, and axial length of duplex clutch assembly being replaced.

Electrical/ Pneumatic Start-Up Kits

Start-Up Kit Includes Valve Assembly, Pressure Gauge, Pressure Regulator, Limit Switch, Quick Exhaust Valves, Fittings, Bracket, Hose and Schematics.

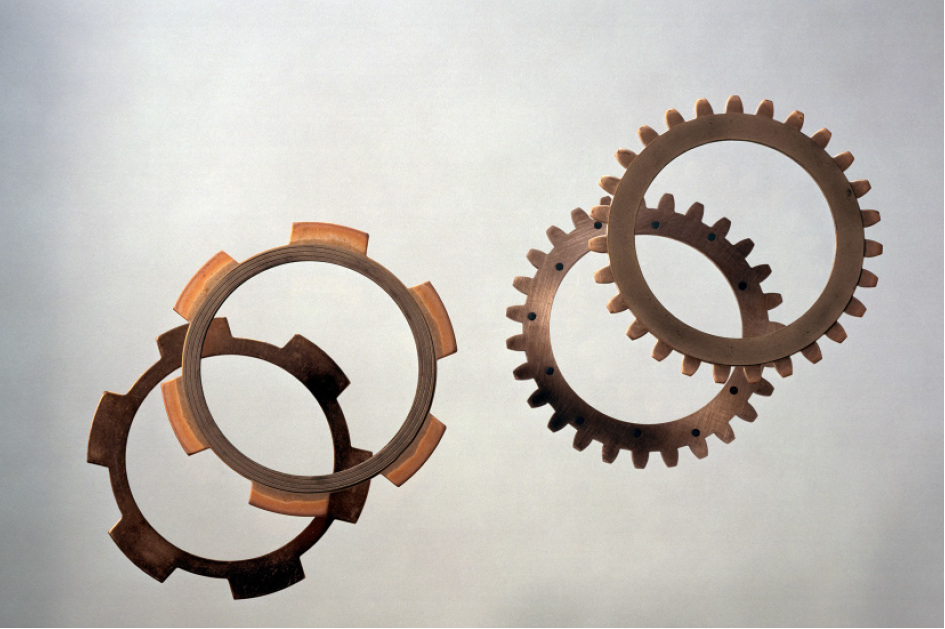

Logan Clutch and Brake Discs

Replacement Friction and Steel Clutch Discs for :

- Twin Disc

- Dana / Formsprag / T.B. Wood’s

- Rockford

- Carlyle Johnson and more…

Applications Include:

- Mechanical Threading Clutches

- Spindle Stopping Clutches

- Mechanical High Speed and Feed Clutches

Longer Lasting Spindle Stopping Clutch Discs

In addition to our line of air/fluid actuated Clutches and Brakes, Logan manufactures and stocks a wide variety of friction-faced and high-carbon steel clutch discs for use in a variety of applications.

Air Threading® is a Registered Trademark of Logan Clutch