.png?width=1440&height=700&name=Untitled%20design%20(7).png)

Increase Your Screw Machine Productivity by 20% or More

Unlock higher output with Logan Clutch Air Threading Clutches, Hi-Lo Retrokits, and Control Systems

Engineered for These Leading Machine Brands

How Logan Clutch Increases Screw Machine Efficiency by 20% or More

Logan Clutch products increase screw machine productivity by 20% or more by reducing idle time and improving cycle consistency. With upgrades like air-actuated clutches, Hi-Lo retrokits, and microprocessor-based controls, Logan helps manufacturers minimize maintenance downtime and streamline operations. The result: faster setup times, smoother indexing, and more parts per shift—without replacing the entire machine.

Learn More About Our Screw Machine Products

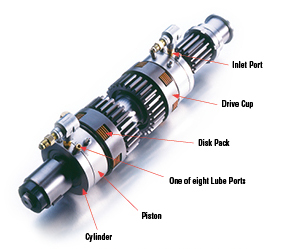

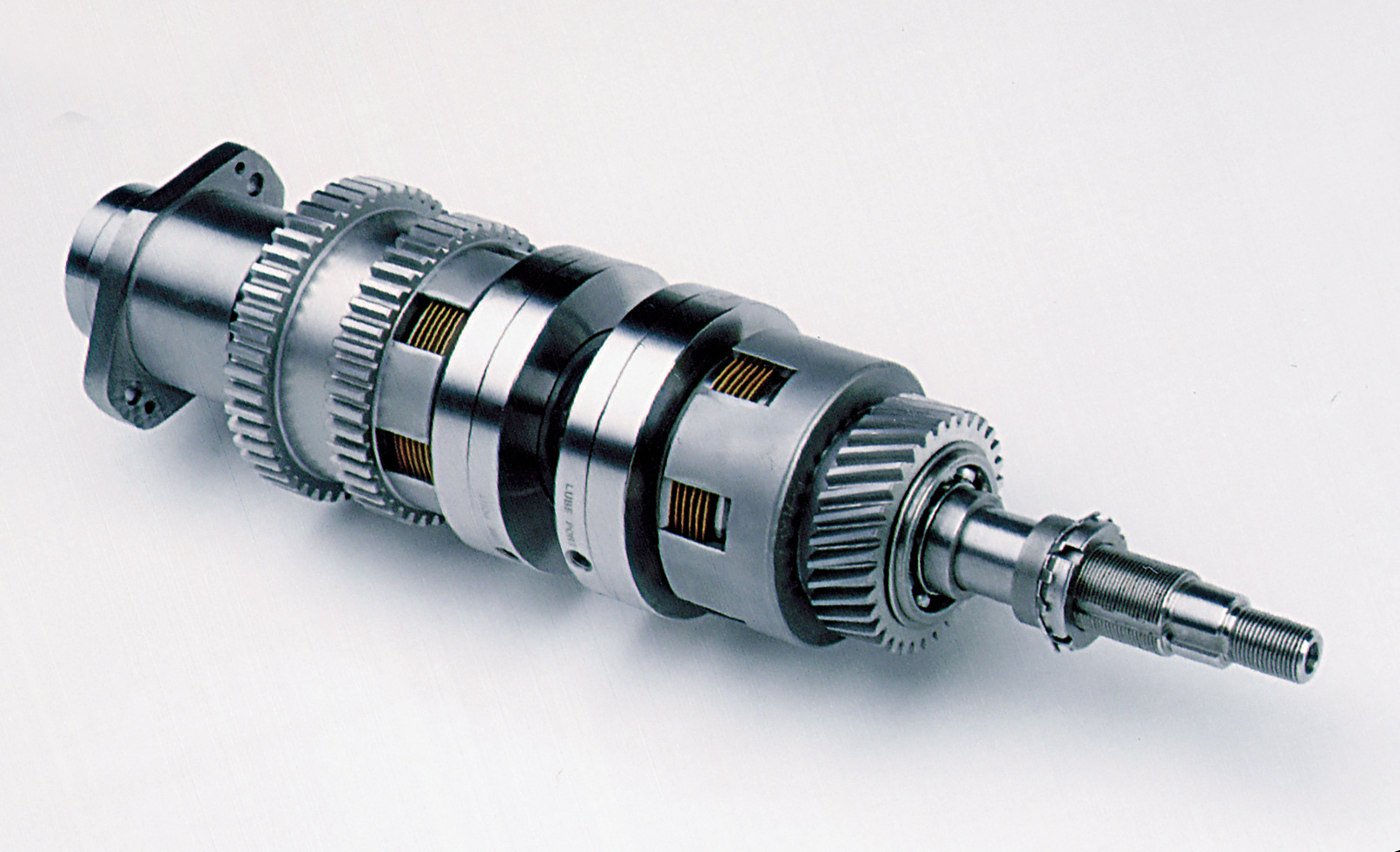

For Your Acme-Gridley Logan Hi-Capacity Air Threading®

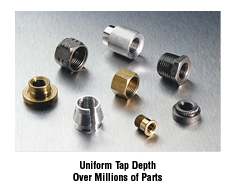

Increase Productivity and Quality

- Self-Adjusting Disc Pack - No Slippage

- Extremely Accurate - Uniform Thread Depth Over Millions of Parts

- Large Cylinder - Piston Area For Maximum Torque

- Up To 200% More Torque Than Mechanical Clutches

Convenient to Maintain

- Increase Tap Life Through Positive Clutch Engagement

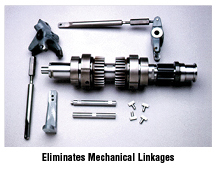

- Eliminates Mechanical Linkages – Lever Arms, Adjusting Collars, Dog Levers, Spring Pins, Yokes, Clutch Sleeves, etc.

- Eliminates Mechanical Clutch Adjustment

Simple to Install

Most Logan Air Threading Clutches Utilize Existing Clutch Drive Cups, (Clutch Gears), Spacers and Shafts

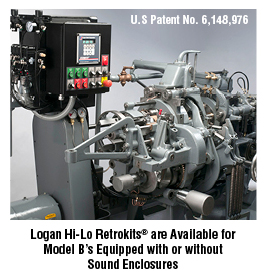

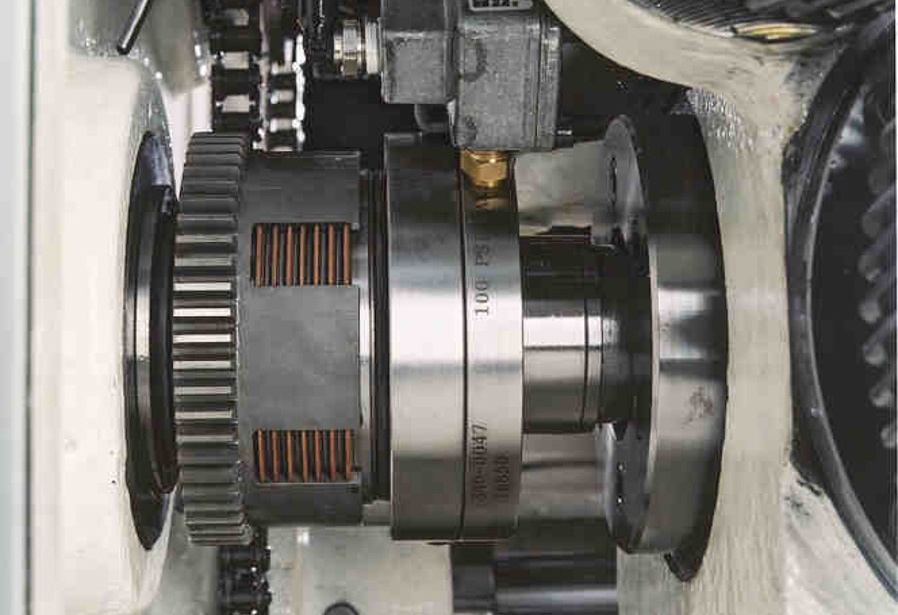

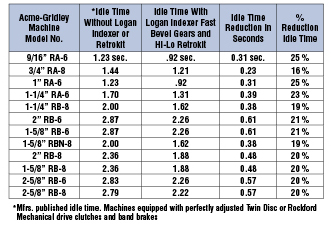

For Your Acme-Gridley Logan Hi-Lo Retrokit

Retrokit® Features:

- Reduces Idle Time Between Speed Changes

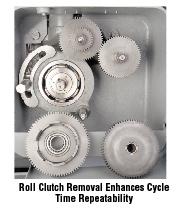

- Replaces Mechanical Clutches, Roll Clutch, Band Brake

- and Linkages with Fast-Acting Air-Actuated Logan Clutches

- Positive, Crisp Logan Clutch Engagement Guarantees

- Cycle Time Repeatability

- Simplifies Clutch Maintenance - No Disc Pack Adjustment

- or Slippage

- Quick-Stop, Power-Applied Brake - Prevents Machine Coasting

Savings:

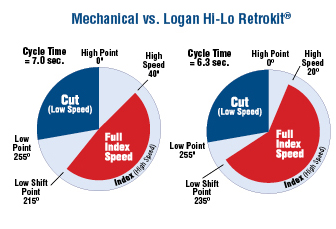

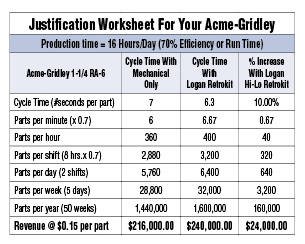

- Increase Productivity From 10-20%

- Tools Can Be Positioned Closer to the Work Piece Due to Repeatable High and Low-Speed Clutch Engagement

- Better Machine Utilization - More Productivity from Existing Machines, Operators and Floor Space

Additional parts produced per year - 160,000 With Hi-Lo Retrokit

Total added revenue to company’s $ 24,000.00 top line, utilizing existing machine, operator and floor space

Above calculation based on 10%

increase in productivity - Varies by machine condition

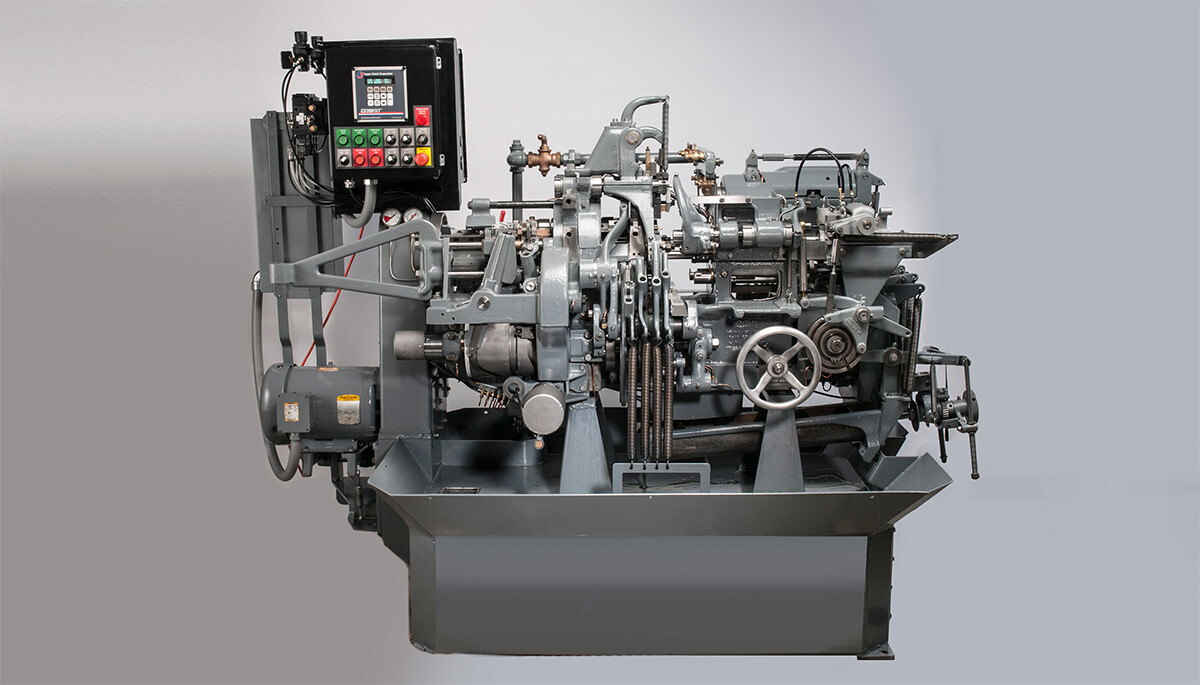

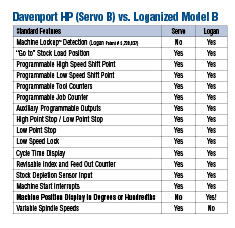

Logan Control Systems - The Logan CS 2001XTPTM Microprocessor Control

The CS 2001XTP is specifically designed to bring new machine technology to your existing fleet of screw machines. With features such as Tool Counters, Thread Check, Machine LockUp Detection, Stock Load and more, the XT offers screw machine users more flexibility during set-ups, and increases overall machine productivity.

All the Features of the XT16 Plus:

- Full Pre-Wired Push-Button Control Station, and Remote Station

- Eliminates Relay Logic

- 35 Programmable Tool Counters

- Air, Coolant, Lube Pressure Monitor Capability

Plus many more features - call for details

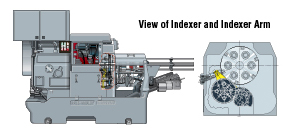

Logan Spindle Carrier Indexing Kits

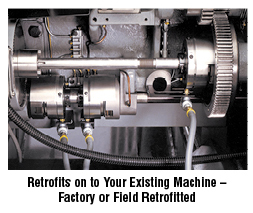

Retrofit Your Acme-Gridley with a Logan Hi-Lo Retrokit and Indexer Right on Your Shop Floor

Reduce Idle Time Between Gear Changes:

- Increase Capacity and Profitability

- More Productivity from Existing Machines,

- Floor Space and Operators

- Better Machine Utilization

- Lower Maintenance Costs

Smooth, Faster Acting Logan Spindle Carrier Indexing Kits for your Acme-Gridley

- Index up to 25% Faster - Save Time, Money and

- Increase Productivity

- Reduce Idle Time Between Speed Changes - More

- Capacity and Profitability

- Requires 75% Less Input Torque - Reduces Maintenance Costs

Reduce Idle Time on Your Acme-Gridley up to 25%

We replace the older Geneva-style indexing mechanism, spiral bevel gears, and Indexing arm on your Acme with our smooth, faster acting Logan Indexer, Fast Bevel Gears and Heavy-duty Indexing Arm

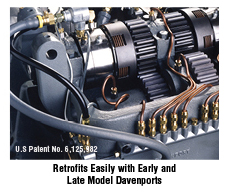

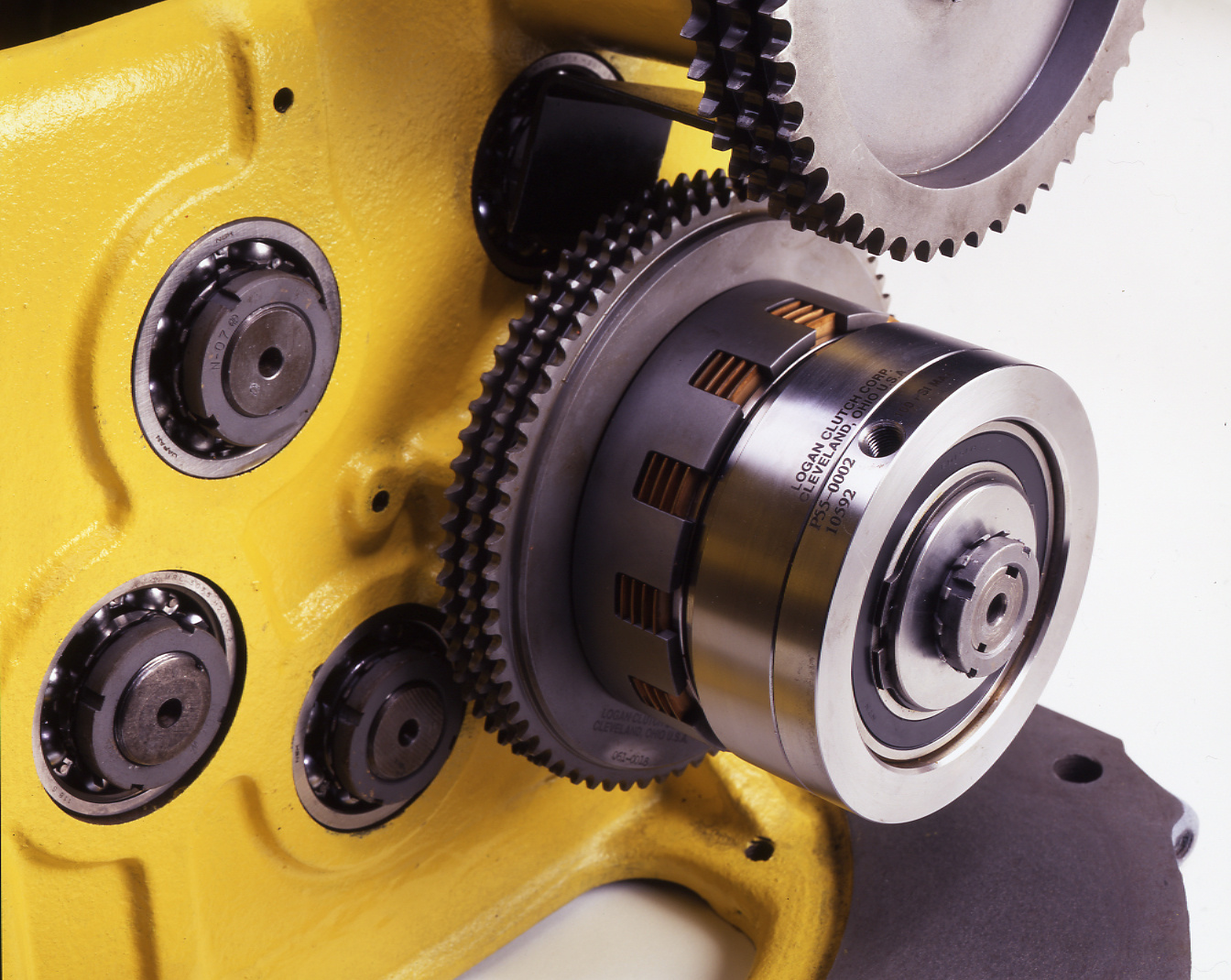

For Your Davenport Model B Logan Air Threading®

Air Threading Clutches are Self Adjusting - No Slippage!

Since Logan Air Threading Clutches are self-adjusting, they eliminate the need for your operator to mechanically adjust the threading clutch, providing your machine operator or maintenance person additional time to troubleshoot more complicated manufacturing challenges.

Retrofits Easily with Early and Late Model Davenports

This new Air-Threading clutch package has been designed to enable users of early and late model Davenports to easily retrofit their existing machines that currently use mechanical threading with this new Logan Air-Threading Clutch arrangement.

Air-Threading is Available on New Davenport Machines Too!

Increase Productivity and Quality

- Self-Adjusting Disc Pack – No Slippage

- Accurate, Uniform Thread Depth

- Increase Tap Life Through Positive Clutch Engagement

Convenient to Maintain

- Eliminates Mechanical Linkages – Lever Arms, Adjusting Collars, Dog Levers, Spring Pins, Yokes and Clutch Sleeves

- In Stock – Disc Packs, Bearing Kits and Seal Kits, Complete With Installation Data Sheets

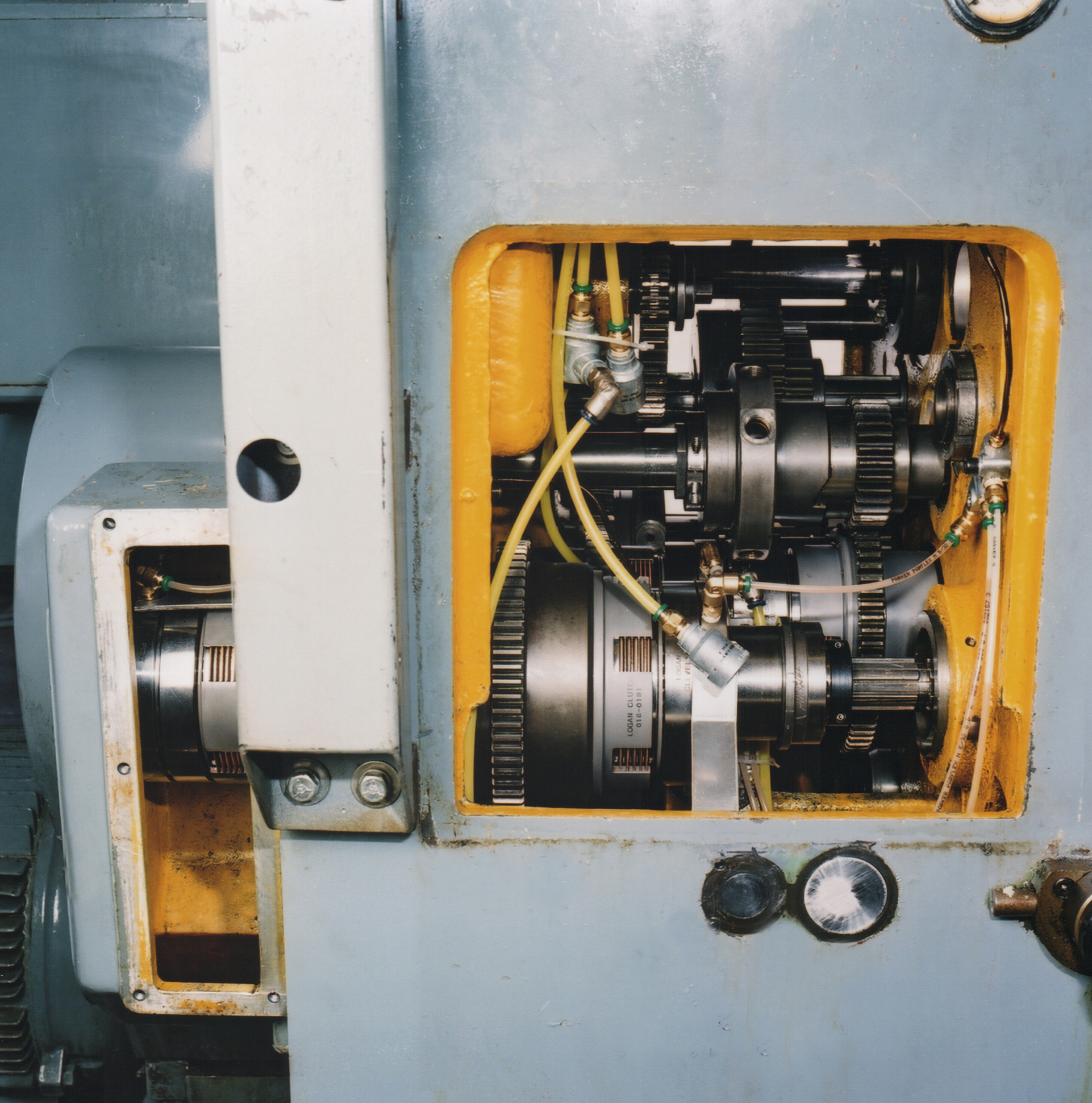

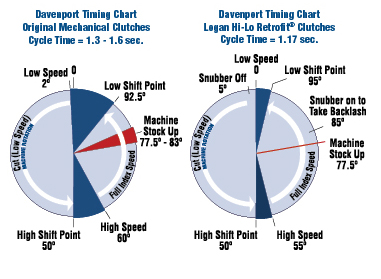

For Your Davenport Model B Hi-Lo Retrokit®

Savings:

- Increase productivity from 10-20%, or more!

- Tools can be positioned closer to the work piece due to repeatable high and low-speed clutch engagement

- Better machine utilization - More productivity from existing machines, operators and floor space

Hi-Lo Retrokit Features:

- Reduces idle time between speed changes

- Replaces mechanical clutches, roll clutch, band brake and linkages with fast-acting air-actuated clutches

- Positive, crisp Logan Clutch engagement guarantees cycle time repeatability

- Simplifies clutch maintenance - No disc pack adjustment or slippage

- Quick-stop, power applied brake - Prevents machine coasting

- Low-speed clutch design reduces idle time while machine operates more consistently

Savings:

- Increase overall machine productivity from 10- 20%

- Reduce cycle time - Tools can be positioned closer to the work piece due to repeatable high and low speed clutch-engagement•

- LockUp detection feature - detects main drum rotation and shuts down your machine if a lock-up condition occurs

“Go To” Stock Load Positioning

- Our power applied brake feature stops your Model B in the correct position to load bars – “jogging” the machine into bar load position during stock up is eliminated – reducing manual load time as much as 50%!

- Stops machine within 1-degree of manual bar load position

- Prevents machine coasting – Minimizes cut-off tool breakage

Ideal for Bar Loaders Too!

- Accurately positions your Model B in the “Bar Load Window” to accept bar stock from bar loaders, and more

Logan Clutch is the market leader in replacement clutches for all brands of screw machines.

Additionally, many machine tool rebuilders rely upon Logan engineering expertise when remanufacturing high-value machine tools.

Logan supplies OEM replacement parts for:

Bullard, Davenport, National Acme, Conomatic, New Britain, Wickman, Warner & Swasey, Giddings & Lewis, Brown & Sharpe, Tornos, and more.