- Home

- Product

- FlexaDrive™ Marine

- FlexaDrive™ Mobile

- Bell Housing Power Take-Off Clutches

- SAE Direct Drive PTO Clutches

- Front of Engine / Front Mount PTOs

- Pump Drive Applications

- CH Series Clutches

- HPC Series Clutches

- LVC Series Clutches

- LCT Series Clutches

- Industrial Hydraulic Clutches and Pneumatic Clutches

- Inter-Mec Clutch-Brake

- Screw Machines

- Clutch Discs

- LoganNet WiFi

- Logan Controls

- Logan Power Packs

- Product Selector

- Industry

- Case Studies

- Literature

- Video

- Contact

Dynamic positioning thruster systems use Logan PTO clutches -

Fast supply vessels are an important part of the supply chain for any type of Wind Farm or Offshore Drilling operation, and each vessel is required to have Dynamic Positioning (DP) capabilities to control its position relative to a specific position, drill rig, wind turbine tower or other support vessel.

Fast supply vessels are an important part of the supply chain for any type of Wind Farm or Offshore Drilling operation, and each vessel is required to have Dynamic Positioning (DP) capabilities to control its position relative to a specific position, drill rig, wind turbine tower or other support vessel.

Dynamic positioning (DP) is a computer-controlled system to automatically maintain a vessel’s position and heading by using its own propellers and thrusters. Thrustmaster of Texas Inc. is a major supplier of DP thruster systems to builders of DP vessels.

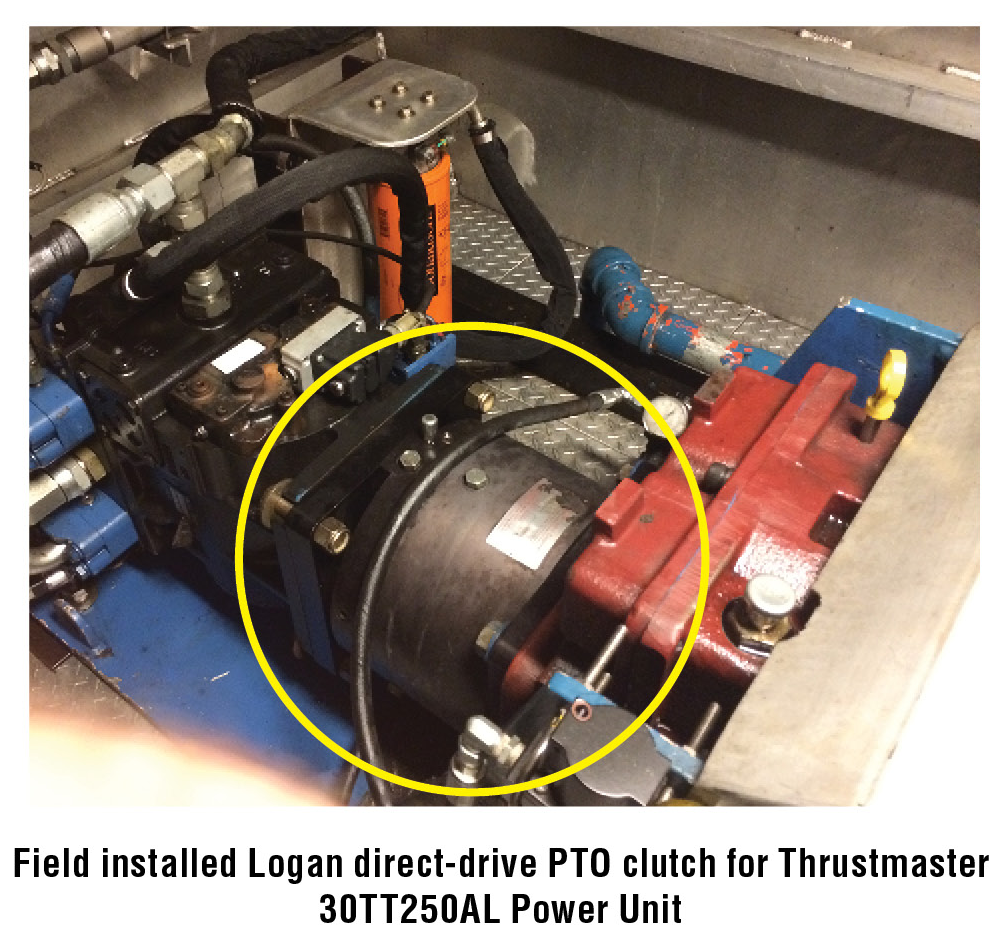

Larger and faster supply vessels (upwards of 200 ft. with speeds over 25 knots) require larger DP systems. One Thrustmaster system, the 250 Horsepower Thrustmaster 30TT250AL, uses a hydraulic motor powered by a large hydraulic axial piston pump (180 cc per revolution). Sandwiched between the hydraulic motor and Durst gearbox is a Logan 1200 Series, air actuated, Direct Drive PTO Clutch to provide on-demand engagement-disengagement to the thruster. The Durst gear box is driven by the vessel’s generator sets.

Logan Clutches lower fuel costs, lower emissions and reduce wear and tear on components

The Logan PTO clutch enables the system to be disconnected when the DP thruster is not required, which results in lower fuel costs, noise, and wear and tear on the hydraulic motor and hydraulic system. Engaging the hydraulic system as  required with the Logan PTO clutch also lowers the overall operating temperature of the hydraulic system, which increases the life of system components such as hoses and other ancillary items. The Logan PTO is also equipped with a SOFTSTART™ system, which enables the thruster to be engaged at idle or at operating speed.

required with the Logan PTO clutch also lowers the overall operating temperature of the hydraulic system, which increases the life of system components such as hoses and other ancillary items. The Logan PTO is also equipped with a SOFTSTART™ system, which enables the thruster to be engaged at idle or at operating speed.

Making the Switch from Electromagnetic Clutches to Logan Clutches

Originally Thrustmaster was using an electromagnetic clutch but found that even the largest electromagnetic clutch on the market could not withstand engagement at full genset RPM, which is required to avoid going into what vessel operators call “darkship” mode where the generators are briefly taken offline to engage the DP thrusters using electromagnetic clutches. Thrustmaster engineers were so impressed by the improved reliability of the redesigned system that they changed the specification of their largest hydraulic system to include the Logan SAE PTO and replace the underperforming electromagnetic clutches.