.png?width=1440&height=700&name=Untitled%20design%20(13).png)

Maximize Power. Minimize Downtime.

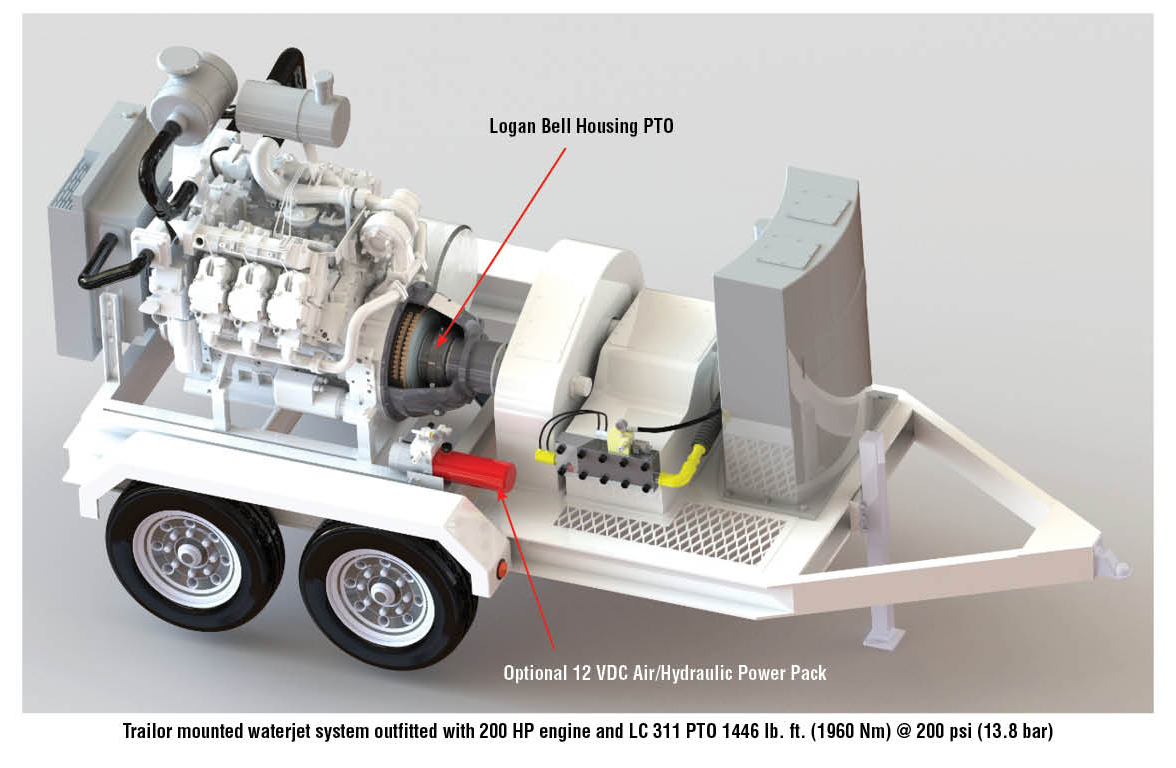

Logan Bell Housing PTO Clutches are built for performance, engineered for efficiency, and ready to work—just like you.

Key Benefits of Logan Bell Housing PTO Clutches

✅ Self-Adjusting:

Hydraulically or pneumatically actuated, Logan clutches eliminate the need for manual adjustments and lever arms—offering consistent, low-maintenance performance.

✅ Smooth, Precise Engagement:

With no linkages or yokes required, you get seamless integration, fewer moving parts, and more reliable operation in the field.

✅ Flexible System Integration:

No fluid or air power? No problem. Logan offers standalone hydraulic power packs, making integration easy across a wide range of driveline setups.

✅ Remote Operation & Control:

Engage the clutch exactly when and where you need to—via panel, remote control, or from inside the cab—for improved safety, convenience, and control.

✅ Fuel Efficiency & Emissions Reduction:

On-demand clutch engagement reduces engine load, helping save fuel and cut emissions without sacrificing performance.

Learn More About Our SAE Direct Drive PTO Products

SPF Series PTO - Direct Drive with Flexible Coupling

PTO Clutch with integral flexible coupling for torsionally active, in-line applications

Features:

- Air or fluid actuated

- Self-adjusting disc pack

- Smooth engagement / disengagement

- Integral torsional coupling for in-line applications

- Available in: B, C, D, E and F splines, plus bore and key configurations

FTPO Series PTO - Direct Drive Short Axial Length

PTO Clutch with through bolt design for low profile, compact applications

Features:

- Air or fluid actuated

- Self-adjusting disc pack

- Smooth engagement / disengagement

- SAE 2-Bolt or 4-Bolt B-Mount

- SAE 4-Bolt C-Mount

- 12 & 24 Volt DC Control valve system integrates with existing transmission pressure

- 30 psi / 2-bar sealed input housing

Logan Clutch manufactures Bell Housing PTO clutches designed for high-torque, heavy-duty applications—and proudly built in the USA.

Our bell housing clutches deliver reliable, self-adjusting performance in demanding environments where fuel efficiency, emissions reduction, and long-term durability are essential.

Applications

- Industrial

- Marine

- Agriculture

- Off-Road

- Mobile Equipment

- Hybrid Vehicles

Ready to enhance your equipment's performance with Logan's Bell Housing PTO Clutches?

Get a Quote Today

Fill out the form below to receive a customized quote tailored to your specific needs.