- Home

- Product

- FlexaDrive™ Marine

- FlexaDrive™ Mobile

- Bell Housing Power Take-Off Clutches

- SAE Direct Drive PTO Clutches

- Front of Engine / Front Mount PTOs

- Pump Drive Applications

- CH Series Clutches

- HPC Series Clutches

- LVC Series Clutches

- LCT Series Clutches

- Industrial Hydraulic Clutches and Pneumatic Clutches

- Inter-Mec Clutch-Brake

- Screw Machines

- Clutch Discs

- LoganNet WiFi

- Logan Controls

- Logan Power Packs

- Product Selector

- Industry

- Case Studies

- Literature

- Video

- Contact

Logan Power Take-off (PTO) Clutches For Mobile Equipment -

OEM Manufacturer of Construction Equipment Works Together with Logan Application Team

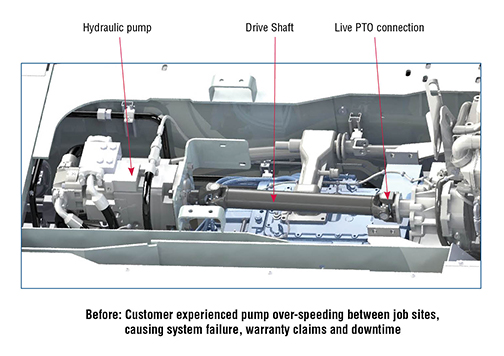

The Challenge: Before

OEM contacts Logan to solve system issues which are causing hydraulic pump failure

Most OEM manufacturers of mobile equipment use hydraulic piston pumps to control machine movements and attachments. In many cases these hydraulic piston pumps are driven remotely from the engine’s auxiliary PTO drive via a slip yoke shaft. Machine Operators must be able to turn these pumps on and off when the vehicle is driven from job site to job site - in order to prevent over speeding the pump when the engine is running faster than the pumps normal hydraulic work speed. There is also the potential for all the pumps to engage at once, which would cause the input torque rating to be above the engine specifications causing hydraulic system and pump failure. In this situation, customers were going beyond the limits of the machine and pump specs – the OEM had to do something quickly -they contacted Logan.

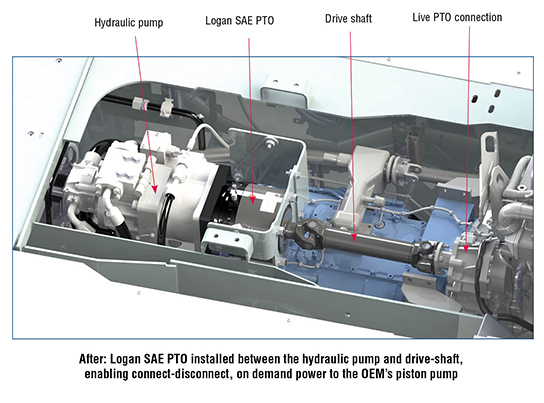

The Solution: After

Logan adapts off the shelf SAE PTO Clutch to meet specific OEM customer need

In most cases the pumps are already defined by the customer, which requires Logan to fit with small envelopes, sandwiching the Logan Clutch in between the pump and engine. After considering all of the options with Logan application engineers, the OEM selected an SAE PTO 1200 Series Clutch. In less than a week, extensive lab and field tests were conducted. Results were positive. The OEM quickly created space to sandwich the Logan Clutch between the driveline and the piston pump – thereby eliminating the possibility of over speeding the pumps. This solution enabled the OEM to keep its customer base happy by eliminating unnecessary machine downtime.