- Home

- Product

- FlexaDrive™ Marine

- FlexaDrive™ Mobile

- Bell Housing Power Take-Off Clutches

- SAE Direct Drive PTO Clutches

- Front of Engine / Front Mount PTOs

- Pump Drive Applications

- CH Series Clutches

- HPC Series Clutches

- LVC Series Clutches

- LCT Series Clutches

- Industrial Hydraulic Clutches and Pneumatic Clutches

- Inter-Mec Clutch-Brake

- Screw Machines

- Clutch Discs

- LoganNet WiFi

- Logan Controls

- Logan Power Packs

- Product Selector

- Industry

- Case Studies

- Literature

- Video

- Contact

Real-World Ind. Clutch & Brake Case Studies -

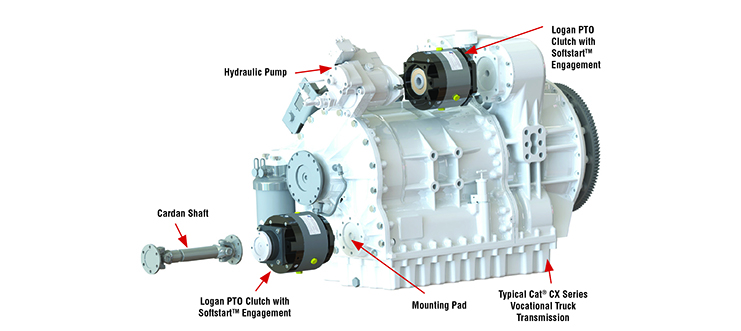

Logan Direct Drive Power Take-off (PTO) Clutches

Logan Direct Drive Power Take-off (PTO) Clutches provide immediate reduction in fuel consumption, greenhouse gas emissions and maintenance

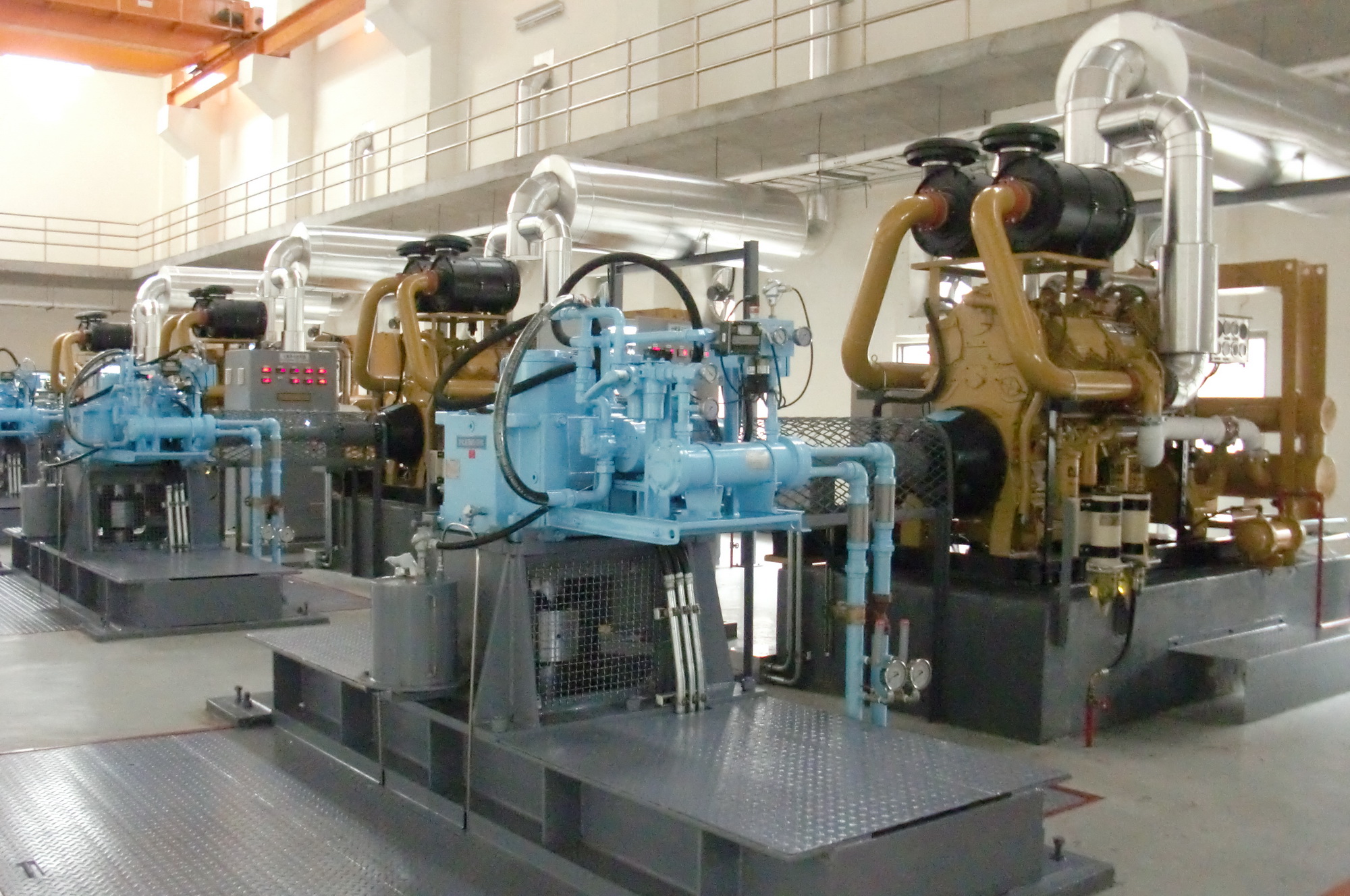

Logan Bell-Housing PTO Clutches for Pumping Stations in Taipei

Logan Bell-Housing PTO Clutches for Pumping Stations in Taipei

Logan Front of Engine PTO Clutches and Scania Engines provide on-demand hydraulic power for the Sailing Yacht Hetairos

Logan Front of Engine PTO Clutches and Scania Engines provide on-demand hydraulic power for the Sailing Yacht Hetairos

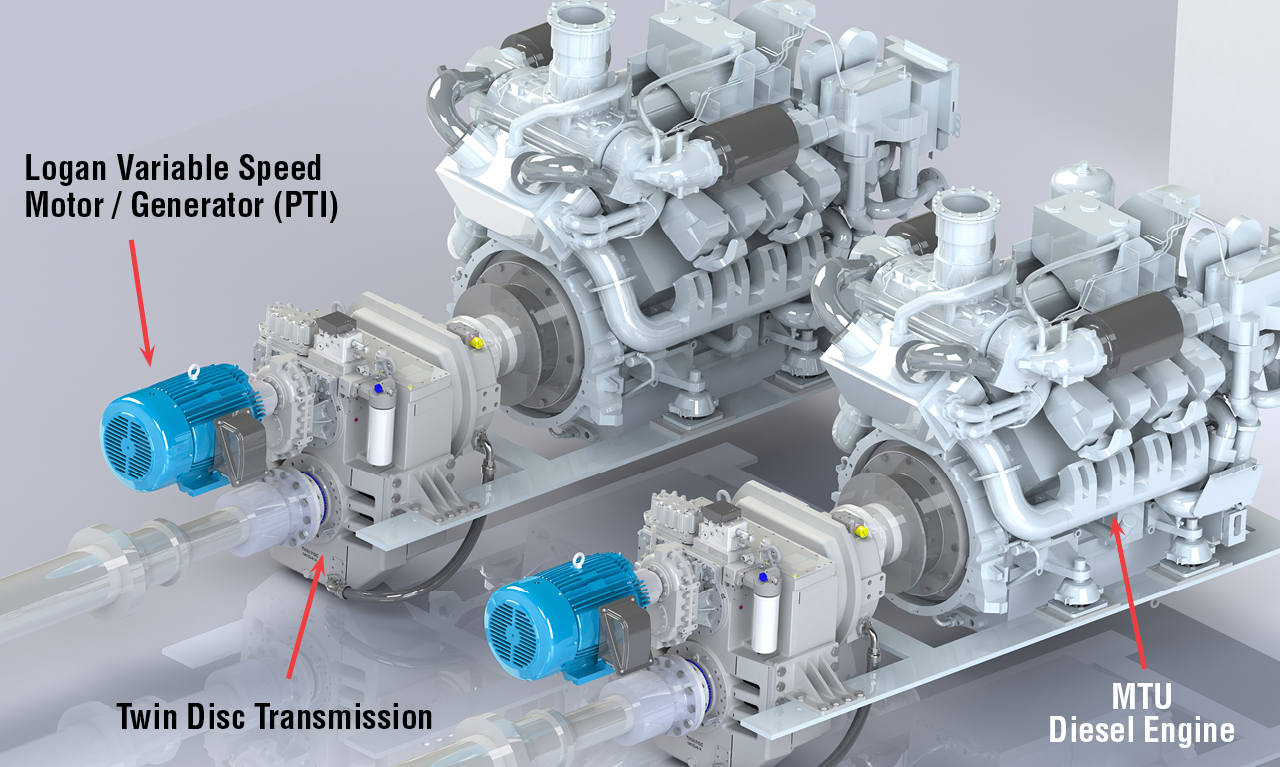

Logan Front of Engine Power Take-off Clutches

Logan Front of Engine Power Take-off Clutches and John Deere Gensets provide on-demand power for the tugboat North Arm Tempest

Logan PTO Clutch Benefits

Logan PTO clutches reduce fuel consumption, operating costs, and greenhouse gas emissions, making them friendly for the world and your

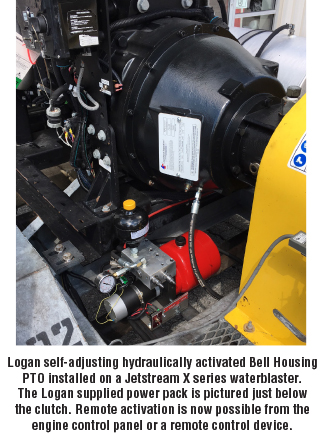

Logan Bell-Housing Power Take-off Clutches

Logan Bell-Housing Power Take-off Clutches for Hog Technologies Waterblasters

Logan Power Take Off Clutches for San Francisco Fireboats

Logan Power Take Off Clutches for San Francisco Fireboats

Logan FlexaDrives for Manure and Dragline Equipment

Logan FlexaDrives for Manure and Dragline Equipment

Logan Bell Housing PTO Clutches for Amsterdam fire-fighting vessel

Logan Clutches heavy-duty Bell-Housing PTO Clutches provides the necessary on-demand power needed for an Amsterdam fire-fighting vessel.

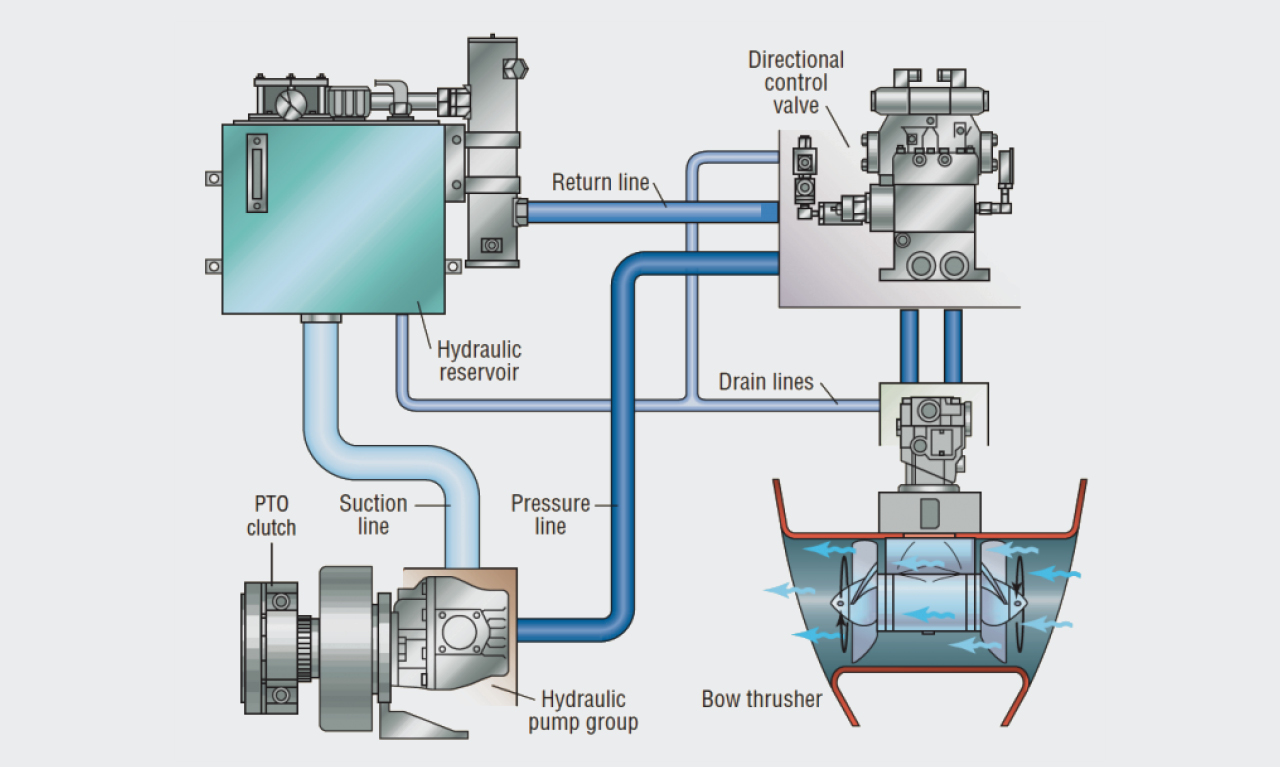

Dynamic positioning thruster systems switch from electromagnetic clutches to Logan air actuated PTO Clutches

Dynamic positioning thruster systems switch from electromagnetic clutches to Logan air actuated PTO Clutches